Arburg, S.A. - Injection moulding machines for multicomponent – multicolor

Arburg

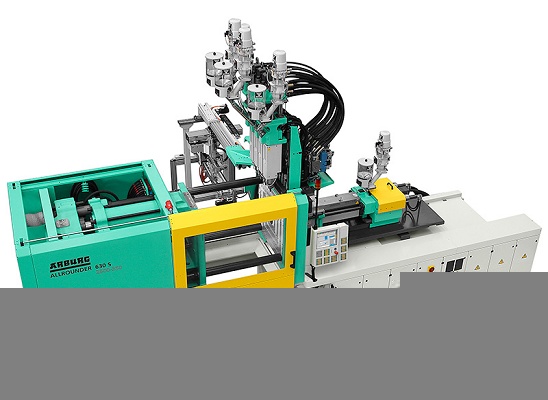

Multi-component injection moulding plant: individual configuration of best suited to each application of multicomponent injection technique

Allrounder modular construction system enables individual settings best suited to each application of multicomponent injection technique. The spectrum ranges from the Allrounder S fully hydraulic with technique of hydraulic accumulator to drive machines fully electric Alldrive series. Either vertical or horizontal, or rotary table, all machines can be combined with the most varied units injection and thus cover the different applications and energy needs.

ARBURG offers an extensive know-how in the field of multi-component injection-many combinations of sizes: up to six independent injection units from one another on a machine.Wachen sandwich, mould transfer technique, spin, plates.

-Numerous combinations of sizes: up to six independent injection units from one another on a machine.

-Development of the process more stable and free programming: all units of injection, mould and robot features unified in the central Selogica control.

ARBURG offers an extensive know-how in the field of multi-component injection-many combinations of sizes: up to six independent injection units from one another on a machine.Wachen sandwich, mould transfer technique, spin, plates.

-Numerous combinations of sizes: up to six independent injection units from one another on a machine.

-Development of the process more stable and free programming: all units of injection, mould and robot features unified in the central Selogica control.