Centrotécnica - C.T. Servicio, S.A. - Injection moulding machines for universal use (thermoplastic)

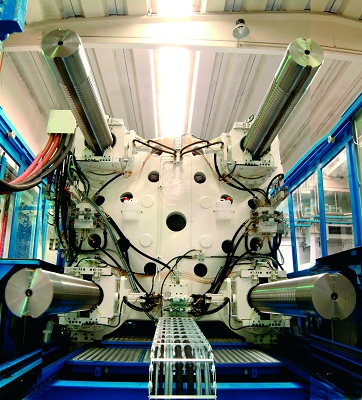

Italtech KS 1.300

Inyectora For PP

The inyectoras produced by Italtech are cream of a wise project and care, oriented to the employment of standard components, with evident economic advantages for the transformers; and with the application of numerous innovations, as és the system of control Alpha 6 and the profile of the husillos devoted to the transformation of materials with high characteristic. By not speaking of the use of electrical motors regulator by inverters on the husillo of plastification with notable advantages in terms of energetic saving certificate, greater productivity and reduction of the environingingmental impact.

Italtech, on the other hand, always has oriented his research to the realisation of able machines to keep, a high productivity and constant in the time; to achieve a fast amortización of the investments; what results an important economic indicator for all.

Italtech Can guarantee these results because it organises entirely the process of production, from the project to the setting, with a constant attention and repeated comprobaciones technical. His inyectoras, therefore, reunen provision of high level , absolutely on line, and even better, of the ones of the greater world-wide producers; comparing the parameters comunmente used such like productivity, quality of the product finished, repetibilidad, absence of errors, modularidad and length in the time.

Also the services pre and post sale, of course, have been organised in way to reduce or cancel the problems of utilisation of the machines. This achieves using diverse modalities (telephone, modem, fax, sms, direct intervention,...) By part of a human team of expert technicians in electronics equipment dealers equipment dealers, mechanical and hydraulics, able to give immediate answers. A very gifted warehouse allows to send quickly the spare parts to cualquie pais European.

Italtech Proposes nowadays, lines of product, so much with closing to kneepad like hydraulics closing, of the type 2 dishes.

The machine presented in Equiplast 2005 of the series KS, has 1.300 t of strength of closing and incorporates the last advances in the type of closing 2 dishes, of high speed and efficiency. It mounts a group plastificador special for injection of PP with long fibre, electrical engine in the load and inverters; what turns it into one of the machines of lower energetic consumption of the sector.

Italtech, on the other hand, always has oriented his research to the realisation of able machines to keep, a high productivity and constant in the time; to achieve a fast amortización of the investments; what results an important economic indicator for all.

Italtech Can guarantee these results because it organises entirely the process of production, from the project to the setting, with a constant attention and repeated comprobaciones technical. His inyectoras, therefore, reunen provision of high level , absolutely on line, and even better, of the ones of the greater world-wide producers; comparing the parameters comunmente used such like productivity, quality of the product finished, repetibilidad, absence of errors, modularidad and length in the time.

Also the services pre and post sale, of course, have been organised in way to reduce or cancel the problems of utilisation of the machines. This achieves using diverse modalities (telephone, modem, fax, sms, direct intervention,...) By part of a human team of expert technicians in electronics equipment dealers equipment dealers, mechanical and hydraulics, able to give immediate answers. A very gifted warehouse allows to send quickly the spare parts to cualquie pais European.

Italtech Proposes nowadays, lines of product, so much with closing to kneepad like hydraulics closing, of the type 2 dishes.

The machine presented in Equiplast 2005 of the series KS, has 1.300 t of strength of closing and incorporates the last advances in the type of closing 2 dishes, of high speed and efficiency. It mounts a group plastificador special for injection of PP with long fibre, electrical engine in the load and inverters; what turns it into one of the machines of lower energetic consumption of the sector.