Sandvik Coromant Ibérica, S.A. - Broaches

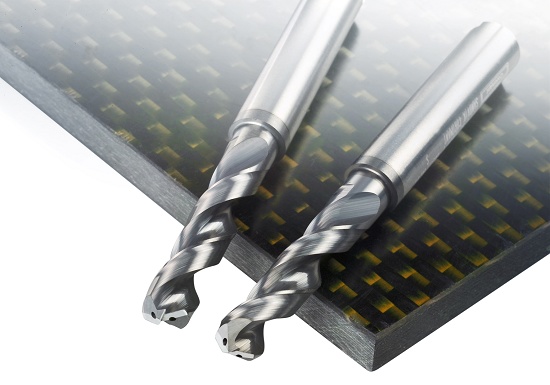

Sandvik CoroDrill 854 y CoroDrill 856

Drills for composite materials: designed for the aerospace sector

To meet the growing demand for the aerospace sector of a reliable and efficient technology to practice holes in composite materials, the cutting tools and systems from Sandvik Coromant tools specialist has the CoroDrill 854 and CoroDrill 856, tools with a special design.

Practice holes in plastic reinforced with carbon (CFRP) requires the use of exclusive geometries to desired bore, tolerance and quality the de-lamination and the chipping are frequent problems. The combination of CFRP with a stacking material such as aluminum, introduces a dimension to the problem, given that both materials require different machining techniques. CoroDrill 854 and 856 are drills designed to meet the stringent demands of the most modern materials of CFRP with packets of aluminium, which offer a homogeneous, long useful life and are able to meet strict tolerances with continuity.

The geometric shape of the 854 CoroDrill is intended to improve the quality of the entry and exit into the hole in materials with a high proportion of fiber. A correct selection of the tool is essential to achieve good results when practicing holes in composite materials: CoroDrill 854 is recommended when there are problems of chipping or desflecado, while customers prefer the 856 CoroDrill if the problem is the peeling in large percentage of resin materials.

The geometric design of the 856 CoroDrill optimizes the performance of holes in materials with a high proportion of resin. Small tip angles and large detachment angles help to improve the quality of the hole, as well as to reduce the axial effort, especially critical in parts with thin wall surfaces. Both CoroDrill products help eliminate burrs and to improve the surface finish.

Typical aerospace applications of the 854 CoroDrill and the 856 CoroDrill include the wing box and components of aerospace structures.