Sandvik Coromant Ibérica, S.A. - Milling cutters

CoroMill 490

Cutters for escuadrar: reduces the cost of machining up to 25 %

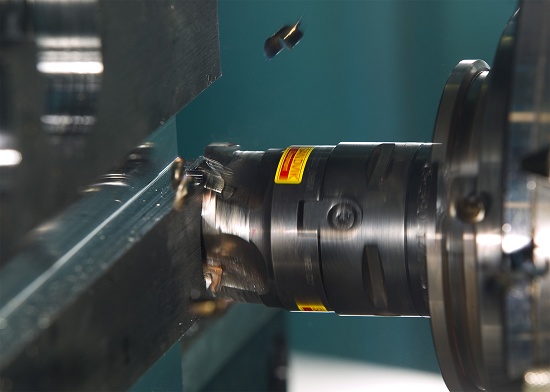

CoroMill 490 of Sandvik is a tool of high accuracy that allows carrying out finished late in a single pass, which makes it ideal for applications in foundries and forges working close to the final dimensions where it is necessary a precise cut.

This is possible thanks to the design of insert with four phyla of CoroMill 490, which reduces the cost per piece of face to the customer. CoroMill 490 can produce a finished product in just one pass. The maximum cutting depth is 5.5 mm, 4 mm optimal recommended. CoroMill 490 can be used as a tool for milling standard, to reduce the inventory of tools and simplify the control of the production. The end result is a lower cost of the milling front and Squadron. CoroMill 490 is used also for contouring, recanteado and milling slot without marks.

CoroMill 490 is available in diameters of 25 to 80 mm (25-125 mm complete once), with handles of type axis, Coromant Capto, cylindrical and Weldon; step L, M and H and available both metric in inches. The plates are currently offered with geometry P and in the future will be available also in M and K.

These new qualities are combined with exclusive geometries with parallel facet, allowing excellent finishes in front and Operations Squadron. Four phyla of court and an improvement in terms of both performance predictability as in precision that the CoroMill 490 is the first to get cut to exact 90º without noticeable edges on a smooth surface (the height of edge is 0.03 mm). CoroMill 490 allows to work with data in court and higher initial values, which implies higher productivity.