Carboneras Internacional - Feeding systems for machinery

G. P. A. Serie A

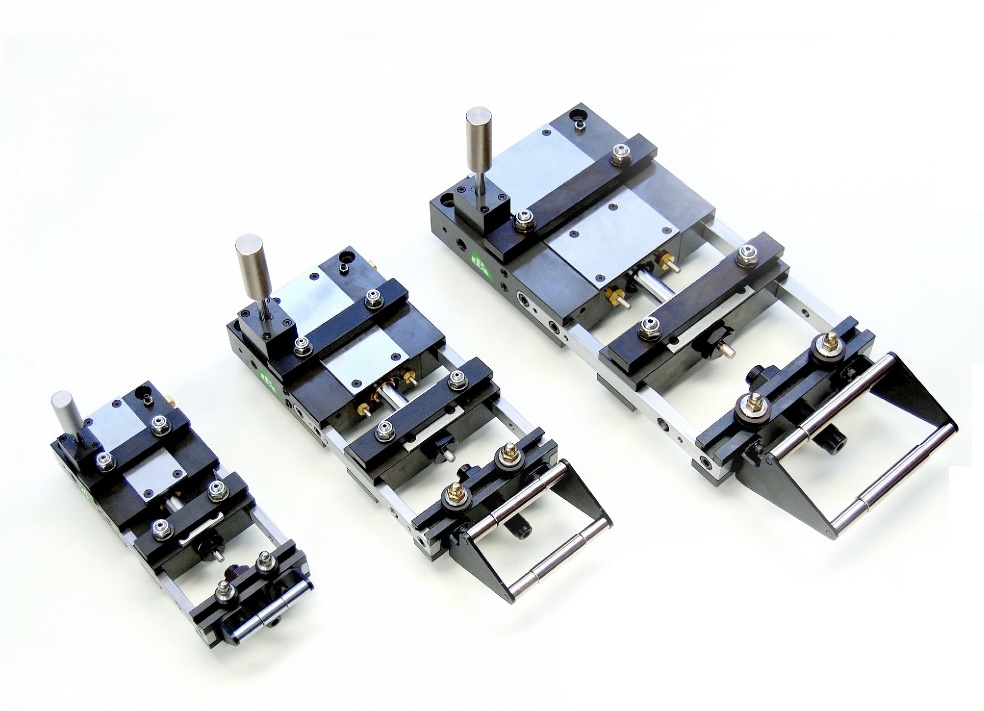

Compact pneumatic feeders: outstanding ease of use and speed in the change of die

Available for wide maximum material 40, 60 and 100 mm, with the possibility of selecting the type of command: mechanical, electrical or pneumatic. instead of die. Direct mounting on the die: reduced dimensions, fast and simplified remote control connections, externally-mounted valves and the possibility of direct mounting in the die, are the main characteristics of these feeders.

Available for wide maximum material 40, 60 and 100 mm, with the possibility of selecting the type of command: mechanical, electrical or pneumatic.

In case of working with die with centering, it is possible to install a kit that allows the complete release of the jaws of the feeder material during the pressing phase.

The reduced dimensions, the rapid and simplified remote control connections and the possibility of direct mounting in the die are the main features of the feeder series that models AN and ANM complement.-Mechanical control: the power supply unit is supplied with a mechanical control valve pressure and command is transmitted directly from the movement of the die or press-mechanical control: the power supply unit is supplied with a mechanical control valve pressure and command is transmitted directly from the movement of the die or the press.a mechanical control valve pressure and the command is transmitted directly from movement of the die or the press.

-Pneumatic control: the power supply unit is supplied with a pneumatic control valve and the command is transmitted signal of the air valve of the press or a Microswitch mounted on the press mechanical cam.

They can also be supplied with two optional accessories:-superior protection: on request provided superior protection resistant polycarbonate for the protection of the upper area of the mobile jaw movement.

-Automatic release system: release kit allows during pressing, the full release of jaws of the feed material. This system is particularly useful in the case of die with centering.

Available for wide maximum material 40, 60 and 100 mm, with the possibility of selecting the type of command: mechanical, electrical or pneumatic.

In case of working with die with centering, it is possible to install a kit that allows the complete release of the jaws of the feeder material during the pressing phase.

The reduced dimensions, the rapid and simplified remote control connections and the possibility of direct mounting in the die are the main features of the feeder series that models AN and ANM complement.-Mechanical control: the power supply unit is supplied with a mechanical control valve pressure and command is transmitted directly from the movement of the die or press-mechanical control: the power supply unit is supplied with a mechanical control valve pressure and command is transmitted directly from the movement of the die or the press.a mechanical control valve pressure and the command is transmitted directly from movement of the die or the press.

-Pneumatic control: the power supply unit is supplied with a pneumatic control valve and the command is transmitted signal of the air valve of the press or a Microswitch mounted on the press mechanical cam.

They can also be supplied with two optional accessories:-superior protection: on request provided superior protection resistant polycarbonate for the protection of the upper area of the mobile jaw movement.

-Automatic release system: release kit allows during pressing, the full release of jaws of the feed material. This system is particularly useful in the case of die with centering.