Walter Tools Ibérica, S.A.U. - Inserts for broaches

Walter Tiger-tec PVD-AL203

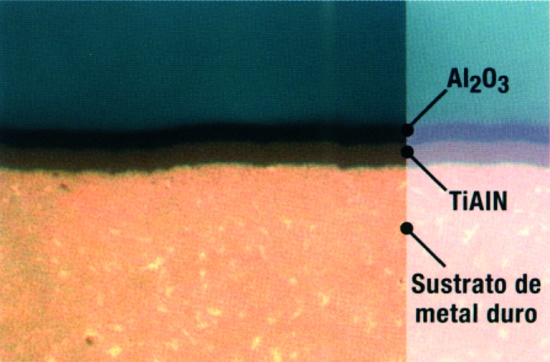

Coatings of oxide of aluminium with the procedure PVD: for the mechanised of materials of difficult start of shaving

The plaquitas of two colours Tiger-tec with the coating indicator and offering until 75% more than performance, turned into the role model to increase the productivity in the mechanised of smelting.

Walter Tools launches Tiger-tec for steel and the materials of cut Tiger-tec applied in the systems of tools Xtra-tec.

Thanks to the development of an innovative coating, Walter Tools has attained to use oxide of aluminium with the procedure PVD on plaquitas of hard metal.

This material of cut offers a hardness, tenacity and resistance to the unknown wear until the moment.

Therefore Tiger-tec PVD-To THE203 is ideal for the mechanised of materials of difficult start of shaving (S) like alloys of titanium or alloys based in nickel, of stainless steels (M) and of steel (P).

With this revolutionary development, his materials of cut Tiger-tec cover more than 80% of all the types of mechanised in the start of shaving.

It allows high speeds of cutting and high hygiene of process.

There are materials like the steels CrNi or titanium in which there is not big advances in decades regarding the increase of quality in the mechanised, something that has not benefited to the industry aerospacial, producers of electrical head offices, producers of installations and of the technical industry of feeding.

The Tiger-tec PVD-To the203 sample an upper power in two main applications at the same time. The material of cut PVD in the degrees WSM 35 and WSP 45 gathers the positive characteristics of the coatings PVD and CVD: edges of sharp cutting, high tenacity and the best stability to the temperature even under the speeds of cutting higher and the conditions more desfavorables.

Walter Tools launches Tiger-tec for steel and the materials of cut Tiger-tec applied in the systems of tools Xtra-tec.

Thanks to the development of an innovative coating, Walter Tools has attained to use oxide of aluminium with the procedure PVD on plaquitas of hard metal.

This material of cut offers a hardness, tenacity and resistance to the unknown wear until the moment.

Therefore Tiger-tec PVD-To THE203 is ideal for the mechanised of materials of difficult start of shaving (S) like alloys of titanium or alloys based in nickel, of stainless steels (M) and of steel (P).

With this revolutionary development, his materials of cut Tiger-tec cover more than 80% of all the types of mechanised in the start of shaving.

It allows high speeds of cutting and high hygiene of process.

There are materials like the steels CrNi or titanium in which there is not big advances in decades regarding the increase of quality in the mechanised, something that has not benefited to the industry aerospacial, producers of electrical head offices, producers of installations and of the technical industry of feeding.

The Tiger-tec PVD-To the203 sample an upper power in two main applications at the same time. The material of cut PVD in the degrees WSM 35 and WSP 45 gathers the positive characteristics of the coatings PVD and CVD: edges of sharp cutting, high tenacity and the best stability to the temperature even under the speeds of cutting higher and the conditions more desfavorables.