This work of investigation has centred the effort in resolving the problematic of manufacture of three particular components: intraocular lens, rings capsulares and implants oftalmológicos of complex geometry

Manufacture of components oftalmológicos with processes of ultraprecisión

H. Urreta, To. Agirre, I. Ayastuy And To. Sanchez of

M. Muñoz of AJL Ophthalmic S.A.

28/11/2013This article collects the work developed in the manufacture of components oftalmológicos, in concrete intraocular lens and optical implants. They present the machines of ultraprecisión used in the processes: Microfresadora, lathe of ultraprecisión and machine of processed laser with pulse ultra short. These machines have been designed and developed for applications between which find the optical components and oftalmológicos.

By means of the microfresado of 5 axles has manufactured an ocular implant in polimetacrilato of methyl (PMMA), with a big esbeltez and complex geometry. This prototype of implant (in phase of world-wide patent) is low clinical essay by a group oftalmológico. On the other hand, they have manufactured intraocular lens and rings of tension capsular in polymeric materials, so much the mentioned PMMA, as in hidroxietil methacrylate (HEMA), and material hidrófobo. In this process has realizar a turning to tip of natural diamond with radius 0,05 mm, with qualities of rugosidad superficial optical, Ra<40nm. And on the other hand it has tuned a process of cut by laser for recortar the lens without that they suffer tensions in the milling, classical process. The components (intraocular lens and implant oftalmológico) have been characterised and measured to ensure the quality and validity of the processes, for what has used a perfilómetro optical 3D as well as a micro-CMM.

1. Introduction

The intraocular lens and in general the implants oftalmológicos are suffering a spectacular increase in his demand, originated mainly by the increase in laesperanza of life and the greater standards regarding quality of life that pursue in the actuality. These assertions sustentan in the studies and forecasts realizar by the OECD in relation to the world-wide consumption in thematic of the health, where integrate the lens and implants oftalmológicos, as well as his impact in the hope of life of the people of the developed countries along the 20th century and first chamber of the 21st century. These studies present of way resumida in the following two graphic, Appears 1:

![It appears 1. Evolution of the cost per capita in thematic of the health 1(to) and hope of resultant life 1(b) [1] It appears 1. Evolution of the cost per capita in thematic of the health 1(to) and hope of resultant life 1(b) [1]](https://img.interempresas.net/fotos/906984.gif)

In sight of the advances that expects finish promoting the market of the health and the one of the ophthalmology in particular, in this work of investigation has centred the effort in resolving the problematic of manufacture of three particular components: intraocular lens, rings capsulares and implants oftalmologícos of complex geometry. In the actuality the greater consumption of product oftalmológico centres in the lens of contact and in his fluids of maintenance. These are product of low cost and copados by the big multinationals of the sector, mainly ALCON and Bausch&Lomb. For companies whose critical mass no scope to the ones of the multinationals the markets that has to pose like aim are the ones of products with greater value added, in sectors of niche and opened to a continuous development by part of the market and the clinics. Like this, and as it can obervar in the following two figures published by Bausch&Lomb in his usual studies of market, the percentage on the global market of the two signatures mentioned surpasses 50%, being the lens of contact his greater market.

The intraocular lens are instead products with greater requests, and like this of greater value added, arriving to be able to be personalised lens for each patient. This market results of greater interest for companies like AJL Ophthalmic, co-author of this work, where can find opportunities of business in the manufacture of complex lens, personalised and far of the big series offered to very low cost by the multinationals. Beside the market of the lens also stand out by interest the devices and physical systems oftalmológicos (figure 2b) with more than 16% of quota of market. It results therefore of this brief analysis of the market the interest in working in complex intraocular lens as well as in devices and ophthalmic implants (systems and devices Appears 2b), where stand out the rings capsulares and personalised implants.

![It appears 2. Quota of market of the main actors (to) and main products that copan the market (b) [2] It appears 2. Quota of market of the main actors (to) and main products that copan the market (b) [2]](https://img.interempresas.net/fotos/906986.gif)

Entered the field of performance of the present work of investigation, to continuation proceeds to detail the processes of manufacture with which have developed the components oftalmológicos mentioned.

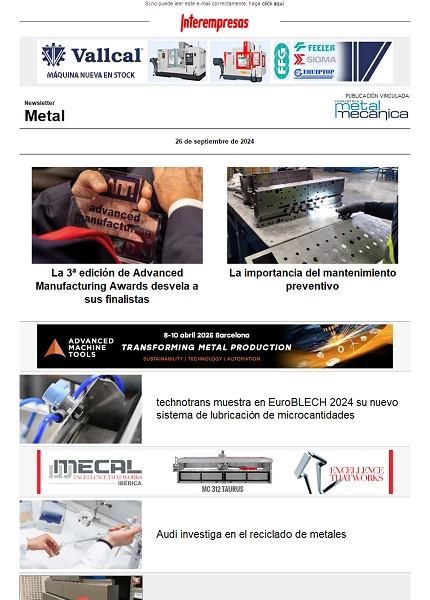

2. Intraocular lens

The intraocular lens are components with optical function that implant in the back camera and previous camera of the corneal cavity of the optical globe, therefore in addition to having of a geometry and superficial finishing of big quality that ensure the sharpness and power dióptrica of the lens, this has to be manufactured in materials biocompatibles. In general the materials used are polymers, PMMA, HEMA and Hidrófobo, in function of some final requests that have to fulfil the lens. Materials that go aditivados with loads so that the lens have properties filtrantes in front of determinate wavelengths of the visible light. To continuation shows the disposal of the intraocular lens in the ocular globe, serving like source of information the unit of learning of AJL Ophthalmic:

For the manufacture of these lens exist in the different market commercial solutions, standing out between them the range Optoform of the house Precitech [4]. Like own solution, in the breast of this project has developed a lathe of ultraprecisión with which manufacture this type of lens. A lathe of three axles (two linear and one of rotation) to work of simple form in spherical lens and with interpolation CNC for any another type of profiles. The structure of the machine is entirely manufactured in granite, with all his guided aerostáticos, linear motors and precision of movement <1μm. The cabezal, also aerostático works until 15.000r/min, being able to be aided by a FTS until 1kHz.

The lens mechanise with tool of natural diamond monocristalino, material that allows a superacabado in the expensive refrentadas, with Ra<50 nm. The tools for this type of application are supplied to global level by Contour Diamond, specialist of the sector. The conditions of cut for this type of application situate around: Vc 300 m/min, F 5 μm/rev and ap 25 μm.

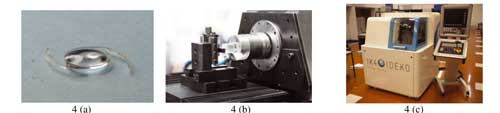

3. Intraocular ring: tension capsular and intraestromales

The intraocular rings, tano the ones of tension capsular like the intraestromales, are elements that use in intraocular operations, like manufacturing of the ocular globe for a back implant of lens or like surgical therapy for the correction of own pathologies of the ophthalmology. These rings manufacture of equal way that the lens in polymeric material biocompatible, usually PMMA. Regarding the process of manufacture divides two-phase, the mechanised to tip of diamond and the cut by means of laser for the obtaining of the ring. In this case, and in comparison to the mechanised of lens, the process of turning is less critical that the one of cut laser by what the focus of interest in this application will put in this last operation. The operation of recortado laser can carry out with machines with different sources laser, being the sources of CO2 the most usual since his wavelength of 10,6μm is very very absorbed by the polymers. In contrapartida this type of do realizar cuttings no very fine, with abundant rebaba in the edges by what generally requires of a process of polishing with which finish the pieces.

For processes of fine cut and processed 3D, has developed a machine laser with a source ultrarápida (ps) Lumera HyperRapid25, with three wavelengths 1064nm fundamental and his two harmonic, 532nm and 355nm. The machine has manufactured entirely in granite, looking for the greater stability in front of variations of temperature and distortions in the time, with guided aerostáticos and linear motors with rules of catchment of high range with which the precision in the volume of the work is <1μm. In the following figure show the intraocular ring of tension capsular mechanised in the machines showed in this work, initial turning of the faces (refrenteado to tip of diamond) and cut laser for the final obtaining of the piece:

For the manufacture of this piece, the parameters of cut of turning have used the same that in the lens, whereas in the processed laser has worked with the ultraviolet wavelength (355nm) for being the one who better precision of cut offers, to a half power of 5W to 200kHz with an advance of cut of 30mm/sg.

4. Implants oftalmológicos

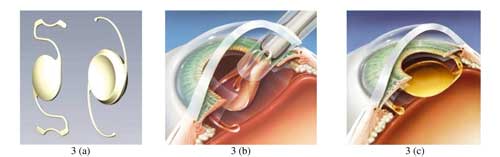

4. Implants oftalmológicos The generic manufacture of implant oftálmológicos customised of geometry 3D complex comports generally the milling in 5 axles with a high precision. For this has split of the microfresadora of ultraprecisión of 3 axles that was presented by Olaskoaga et al. 2010 in this same forum. Taking like base said machine has developed a microfresadora of five axles, nearer to the real needs of the market since the limitations that presented the work in three axles left the previous machine out of a big fan of possibilities. The restrictions that involves the work with 5 axles, being the main the loss of rigidity by the greater cinematic complexity, sees limited by the low strengths that generate in the micromecanizado, generally <5N. Like this, the rigidity that offers the solution of 5 axles adopted in the microfresadora follows allowing that the real precision in all the volume of work situate <1 μm. In this case it presents the mechanised of an implant for the correction of deformations of the ocular globe, an implant with a relatively complex geometry and with an esbeltez in one of his noteworthy walls. This piece is entered in the ocular cavity of the patient, exerting pressesure against the globe, by what has to be manufactured in material biocompatible of medical degree, that stop this concrete case has been again the PMMA. Splitting of material in bar obtains the monolithic piece showed in the following figure:

The mechanised of the implants has realizar with different tools of carbide of tungsten, with diameters from 1mm until 200 μm, all with propeller to 30º and two edges. The basic conditions of mechanised have been S40000 r/min, F2000 mm/min, with depths of mechanised of ap200 μm and ae100 μm.

References

[1] OECD Healt Dates 2010

[2] Bauch&Lomb Market Survey 2009

[3] AJL Ophthalmic S.A. Group of communication and learning, 2012

[4] Precitech 2013 http://www.precitech.com/product-overview/ophthalmic-overview/

[5] Olaskoaga et al. Proceedings 18 Congress MH INVEMA, 2010