Spark-erosion and mechanised of high speed: up to date technologies for the challenges of the medical industry

From GF AgieCharmilles have seen that to keep in the line of continuous evolution and can answer to the high exigencias of the medical sector, is indispensable to invest in technology, development and select painstakingly the processes of manufacture more suitable. It exists a clear tendency to the miniaturisation of the components for the achievement of operations increasingly complex or the realisation of interventions less invasivas. On the other hand the diversification of the materials of medical application also has his effects in the evolution of the technologies employed for the manufacture.

Like this is as from methods already known such as the spark-erosion (where AgieCharmilles is pioneering and at present is celebrating the 60 anniversary of this technology) and the mechanised of high speed or more known like HSM, are technologies that have gone evolving and improving to be able to keep to the avant-garde of the processes of mechanised.

But which is the field of application of these two technologies and which advances contribute to the medical sector?

The spark-erosion, increasingly sophisticated

For the neófitos, the spark-erosion bases in the electrical conductivity of the piece to mechanise. The application of a difference of electrical potential between an electrode situated to a short distance of the piece creates a channel of ionisation in the dielectric where is submerged. A spark generates and the implosion of plasma in the channel comports the start of material by erosion of the piece.

With an electrode of form, can obtain cavities of complex geometry by means of the called spark-erosion of penetration. Instead, if it employs a thread like electrode, with his trip obtains the cut of ruled surfaces with the spark-erosion by thread.

This technology allows the obtaining of complex forms and keep degrees of tolerance very narrow as well as finished of big quality. The field of his application limits to the conductive materials. With the EDM, does not exist physical contact between tool and piece, therefore the efforts of cut disappear. This allows to exceed the limits of the viable with common processes as milling and rectified, especially when they look for the borders in the miniaturisation of the components. In this field, the process is very reliable and economic, even in the most complex applications or the materials of difficult mechanised for other methods.

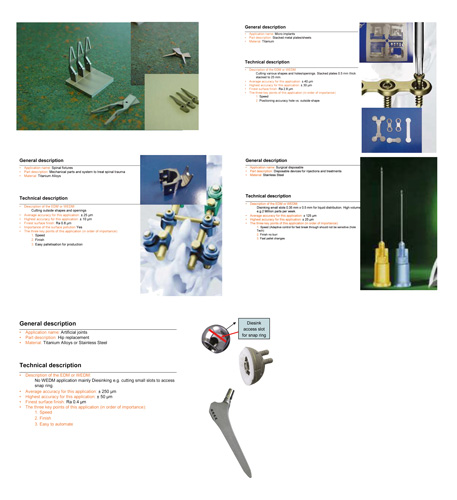

The evolution of the machines of spark-erosion has allowed important and attractor trucks advances for the industry of the medical sector. Generators of high provision that do not alter the properties of the materials (known like CC or Clean Cut), new softwares with technologies of specific erosion for the distinct materials, machines of cut by thread with double cabezal to work with different diameters of thread, the employment of additional axles of rotation of piece, systems of robotización and automation, are some of the advances that have produced to improve the productivity of the spark-erosion and expand the fan of his application.

Numerous challenges posed by the elements to manufacture for the medical sector find his solution with these advances. Like this the work of pieces of small dimensions (inferior to 10 mm2) goes back more accessible and opens new horizons with the maximum reduction of internal radii with cuttings of thread until 0,02 mm of diameter, the absence of rebabas in piece and the maximum superficial quality.

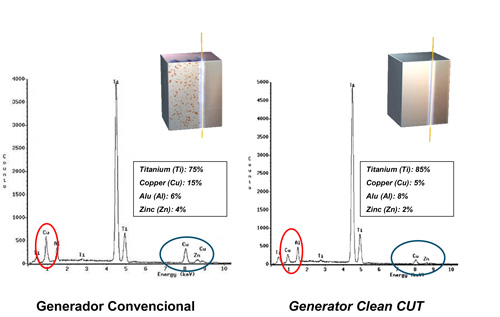

For the implantología and the manufacture of surgical material, the progress of the spark-erosion, with the generators CC “Clean Cut” and the technologies of cut adapted, has contributed improvements no only reducing the times of production, but also in the obtaining of clean “surfaces” reducing of considerable form the superficial pollution of derivative piece of the process of cutting and degradation of the thread. Like this, apart from a greater quality of superficial finishing, obtains also a lower pollution of the piece and alteration of his chemical composition in the superficial zone. Like example, in the cut by thread of pieces in alloys of titanium, the generators CC Clean Cut avoid the oxidation of the titanium and leave the surface exenta of brass and zinc from the degradation of the thread.

Advances in milling

The technology of the milling also has known to evolve to keep to the avant-garde of the productive methods for the medical sector. The mechanised of high speed has done gap and is one of the processes of greater growth at present in the field of the implantología. The new technicians of mechanised, the evolution of the machines and the tools of skilled cutting allow to take out greater performance to the milling. Well it was for the already known alloys of titanium, chromium cobalt and other stainless steels, also has gone adapting to the apparition of new plastic materials, composites or even ceramic that extend in the field of application of the medical industry.

With the mechanised of high speed HSM, as his name indicates, increases the speed of cut between tool and material. This has an effect of increase of local temperature in the zone of cutting and evacuation of the heat with the shaving or material given off. The efforts of cutting reduce considerably, the capacity of start of material increases and achieve better superficial qualities and dimensional precision of piece.

Technological advances like the employment of electromandrinos of high frequency, that can do turn the tool until more than 50.000 revolutions by minute, the afianzamiento of the technology of linear motors, the direct transmission in the axles giratorios of the machines of 5 axles and the evolution of the numerical controls have gone maturing this technology endowing it of a greater versatilidad and expanding his spectrum of application.

The current tendency comes marked by the employment of machining centres of 5 axles with provision of high dynamic and acceleration. These characteristics contribute considerable advantages to give solution to the challenges of the mechanised for the sector. The employment of 5 axles (3 of linear trip and 2 of rotation) allows to give to the tool the ideal orientation with regard to the piece at all times. Like this it can access to levels of geometrical complexity elevated of productive way. The big dynamic of trip in the mechanised, no only in speed but also in acceleration, contributes in the first place a reduction of time of production. For the process of cutting also causes a stabilisation and improvement of the conditions of cut for the tool. This translates in a reduction of the wear and therefore increase of the useful life of tool, improves like this the superficial quality obtained even in materials of difficult mechanised. The result are pieces of high complexity in lower time, with maximum quality and precision and an optimisation of costs of tools.

A key point to take out the maximum provecho of this technology is the development of the automation and gestión of the process. In effect it is seeing as in the sector grows the demand of systems of automation. By a part with the robotización of the machining centres and by another in systems of programming CAM increasingly automatic and specialised for concrete applications. The automatic gestión of the information is also a key point to keep the trazabilidad and minimise the errors during all the chain of process.

Technology in the dental field

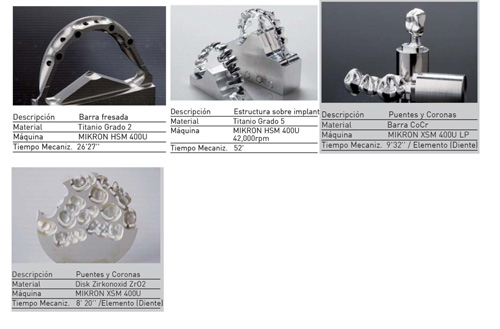

A clear example where the mechanised of high speed to contributed big changes is the sector of the dental prosthesis. From it does some years is experiencing an authentic industrial revolution. It is happened of manual processes that reveal authentic craftsmanship to systems entirely numerizados.

A new chain of process with digitalisation, design CAD, programming CAM and manufacture by milling of high speed is already a reality in this sector. In base to this technological solution have developed the called centres of milling. The fan of solutions is very wide being able to resupply from small centres for one or several prothetic laboratories until centres industrialised with capacity of international coverage.

To give answer to the demand, so many manufacturers of machine, like developers of software of design and programming, as well as the providers of tool have known to adapt to offer integral solutions based in this technology. The result is the obtaining of cells of skilled manufacture devoted to concrete products but with the sufficient flexibility to adapt to the specific requirements of each user, material, method of manufacture or typology of piece.

At present, exists a big variety of materials so much in composition as in formats to work in the medical application and the proportions of his utilisation are in constant change. This supposes a challenge for the technological development of machines. In effect, it is necessary that the productive means are specialised to attend to the needs of a product or specific material, but have to be at the same time flexible to be able to evolve and absorb the changes with new designs or new materials.

Are not the same provision that ask to a machine that have to manufacture prosthesis of You or CoCr that to which employs to mill zirconio, resins, neither neither disilicato of lithium or other ceramics. If some materials require the use of refrigerante for mechanised, others exclude this option, the start can generate shaving in some cases or abrasive dust in others. The magnitudes of strengths of cut generated are totally distinct. By all this, the design of a machine of high provision has to give him the sufficient flexibility to adapt to the different situations and requirements without having to suffer losses of performance or have to be subjected to important modifications. An equipment to the letter has to allow him confront to the maximum of situations and problematic.

The current demand and the evolution of the manufacture for the medical sector demand a combination of leading technology and know do to face the exigencias of the present. In a market in constant change where the competitiveness has gone back an imperative, no longer suffices with having the best equipments or machines more vanguardistas to create the newest products. The profitability demands to take out the maximum performance of the productive means.

Processes like the spark-erosion or the mechanised of high speed have known modernizarse and face up to the changes and tendencies that marks the sector. Like this they appear increasingly skilled technical solutions to answer to problematic concrete.

However exist some clear tendencies in the technological demand of this sector. The manufacturers of this industry ask integrated cheese cheese solutions and the support of technological collaborators, more than simple providers of equipments and machinery. The productivity goes through the automation of the chains of process and the robotización of the machines for maximizar his potential. Finally, the solutions specialised can not go argued with the flexibility if they have to face the challenges of the future with the technology of the present.