International machinery at the EMO 2007

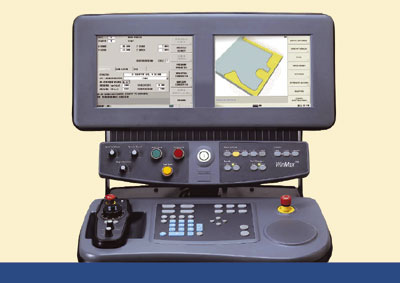

High programmability control system

Machinery international booth has Winmax, a control system of high programmability, designed for numeric control centres (multiple, Swivel Head and horizontal axis), fast and easy to use, which incorporates advanced verification graphics that allow 3D designs with dynamic rotation and a viewing of the piece from any angle without having to redibujarla... It also allows a simulation of the piece in 3D in real time, with graphical display of the tool mecanizing the piece. In addition, it has graphics and options for storing notes and information of the provider. This software simplifies the programming of contours 3D in a single block of data. It enables the design of contours such as cavities or islands with departure angles.

Winmax also includes interactive touch screen, automatic geometric calculation, parallel programming, automatic calculation of progress and speed, input data ergonomic, rotating and tilt, console 1.7 GB, USB interface program memory and up to 512 MB RAM and graphics of simulation.

Machining centres

Hurco has the Centre of multiple and horizontal machining HTX 500, with a few tours of 710 x 610 x 610 mm (2 x pallet 500 x 500 mm), axis (b) rotating continuously and automatic pallet change. The VMX 42 SR model is a 5-axis machining easy to program on site, with a few tours of 1,060 x 610 x 610 mm, an angle of 360 °, and a fourth axis that allows work pieces up to 600 mmWhile the model VMX 84t offers a few tours of 2.130 x 865 x 760 mm, to a maximum of 12,000 rpm. For its part, the VMX 50 models t and VMX 60 t working at 12,000 rpm, with a few tours of 1,525 x 660 x 610 mm.