Precise cut of metal by means of thermal sensors technologies

22 February 2012

Vanad 2000, manufacturer of machines situated in the Czech Republic, offers the last solutions CNC for mechanised of metals. The maximum precision in the cut and efficient use of the thermal sensors power have converted his solutions in international norms in the industry of machinery of cutting. Founded in 1994 like ‘Vanad, spol ro. S', the origin of the company was the modernisation and renewal of scheme ancient, together with the development of his own machines to work metals. In 1996 the company went in in the European market and later in the year 2000 moved his activity to the world-wide market. Because of the remarkable evolution and growth of the company, in 2008 built a new plant of production, specifically in the population of Goalčův Jeníkov (south of Prague). With this new plant increased the capacity to manufacture machines to cover the increasing demand and satisfy the needs of the customers all over the world.

Energetic efficiency in the cut of the metal

Vanad 2000 to.s. They are specialists in solutions CNC for the cut of metal (in shape of leaf) using the technologies of oxigeno and plasma, including the most demanding applications with plasma of high definition. Depending on the resistance of the material required and the quality of cut, the machines of cut can instrument with sources of plasma for thicknesses of metal of 1 to 100 millimetres or antorchas of oxygen for thicknesses of 5 to 300 millimetres.

All the machines that offers Vanad have a simple and fast manufacturing of the paths of the antorcha thanks to the use of different applications CAD/CAM. His modular structure does ideal this solution CNC for his use in the factories of cut with soplete. At present, the machines use mainly in the production of steel, rail technology, production of power, automotive sector / nautics construction, repairs, metallurgical industry in general and skilled metallurgical industry.

The cycles with high speeds of communications ensure some cuttings of high precision

Reach the maximum quality in the cut of the edges represents a new challenge for Vanad. Regarding the construction of the machine require structures highly solid, 100% of precision in the portico together with the antorcha and guides of support. Of great importance also are the transmissions that have to lack holguras, as well as also it requires an accurate selection of a system of suitable control. The ideal system is the one who allows to keep a constant speed and ensure the precision, in addition to an exact repetition of the movements of the antorcha.

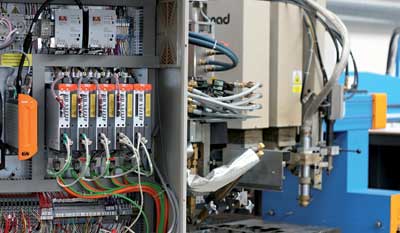

To fulfil with all these requirements, Vanad chose the platform of industrial PC of B & R. The modularidad of the system allows future expansions. The drivers for the servomotors Acopos use to ensure the exact position of the sources of plasma, soplete of oxygen and laser. The short times of sampling and the cycles of communication of 400 us guarantee a process of production without problems. Modules of entrances and compact exits X20 by means of communication Powerlink, guarantee the lower times of answer and a high speed of transfer of data, between the different stations and equipment connected to the network of communications in the machine.

Vanad Also opted by the platform Power Signpost of B&R to improve the ease of use in the machines of CNC. In the graphic screen of high resolution show the elements with an intuitive guide of operation in addition to a help to the operario, that avoids the introduction of erroneous parameters. The engineers of Vanad benefit of the integrated cheese cheese diagnostic, the fast times of start and the simple remote maintenance. The new solution also guarantees the high quality and precision in the cut, in addition to the low cost in the service for operations of hygiene. This has helped to the company Vanad to turn into one of the world-wide leaders in the supply of machines with technology of cut by oxygen and plasma, in addition to tools in the area of machinery CNC.