Article extracted of the

Utilisation of the conformed incremental of sheet to manufacture piece of industrial appliance

B. Urrutia And N. Aranzabal, of Fagor Industrial; To. Blond and M.L. Penalva, of Tecnalia Industry and Transport

23/09/2013To keep his position in the sector of the industrial appliance Fagor Industrial needs to reduce the terms and costs associated to the launching of each new series of products. The conformed incremental is a technology of transformation of sheet that could offer a solution to this problem of terms and costs. His capacity to manufacture pieces of complex geometry joined to the low cost in equipment would allow to manufacture prototypes in sheet of fast and economic form speeding up like this the stage of design and guaranteeing the validation of the final design. Even it could be a solution to manufacture final piece or simplify coin them in the cases of the series of minor thrown. By this reason, Tecnalia has realizar an experimental study oriented to evaluate the technical feasibility of the manufacture by means of conformed incremental of a group of representative pieces of the sheet metal pieces that Fagor Industrial produces. The results obtained reveal that the technology is able to obtain a good part of the pieces considered.

Fagor Industrial is an integrated cooperative in MCC (Mondragón Cooperative Corporation) that offers equipment for collective catering and lavandería mainly with products of own manufacture. Created in 1960 like a department of Fagor Appliances for the commercialisation of industrial kitchens headed to the hospitality industry, in the actuality offers a wide range of products of cooking, washed of tablewares, ovens, lavandería, cold industrial and distribution, is leader of the sector in the national market and a concerning world-wide level with presence in more than 90 countries. To keep his position of leadership, Fagor Industrial is conscious of the importance to offer to his customers the most innovative products and of the maximum quality looking for a balance with the costs and terms associated to said products. In this sense, one of the points of improvement identified by the company is the reduction of the terms and costs associated to the launching of each new series of products.

The design of any new product is an evolutionary process in which from an initial concept go developing different versions, well of successive or simultaneous form. When treating of products of sheet, until the design does not validate does not launch the manufacture of the troquel. The reason is the high cost of coin them of tooling (30.000 and €50.000*). Like result, between the stage of design and the launching of the production exists a period of inactivity for the manufacturer that delays the exit of his product to the market. The problem aggravates with the terms of delivery of coin them (3-4 months*). On the other hand, during the stage of design is necessary to work with prototypes to realizar functional proofs (setting, estanqueidad, others) as well as to validate the design with more reliability. In front of the absence of coin specific the prototypes manufacture basically from sheet cut and soldered. Logically, it treats of pieces that do not reproduce the design to 100%, which hampers the validation of the design and does that it result less reliable. Sometimes it arrives to suceder that launched already the manufacture of the troquel or even once manufactured enters a change of design of last hour. In these cases, to the additional delay of the launching of the production joins a considerable increase of the costs. Obviously, what lower is the size of the series (25/50/100…500 pieces*) more critical results the problem.

Note*: according to data of Fagor Industrial

1. Solution posed

In front of the problem of terms and costs associated to the validation of the design of new products explained in the previous section, Tecnalia proposes to Fagor Industrial analyse the feasibility of the conformed incremental asymmetric of sheet to manufacture his prototypes. The utilisation of this technology would allow to obtain pieces of identical geometry to the one of the design of fast and economic way, speeding up like this the stage of design and guaranteeing the reliability of the validation of the final design.

The conformed incremental and asymmetric is a technology of conformed flexible that proposes often like solution to the problem of the reduction of the size of the series to the that confront at present a lot of transformers of sheet. Unlike other technologies of conformed flexible (p.And. hidroconformado, conformed electromagnetic) that when requiring of a matrix are advisable from a minimum size of the series, the conformed incremental results indicated for cases of ‘unitary pieces' (prototypes, series very reduced) because it is possible to work without troquel and even when it resorts to this option treats of a support of easy and cheap support to manufacture. Thus, further of the manufacture of prototypes the technology can be useful to manufacture pieces or simplify coin as long as the size of the series justify it economically.

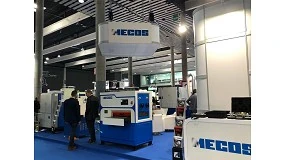

The conformed incremental asymmetric of sheet bases in the plastic deformation located and progressive of the sheet under the action of a tool type punzón that follows a continuous path and numerically controlled. The operation of conformed carries out without the use of coin or using a support of support manufactured in materials of low cost and easy to mechanise (wood, resin or similar). Therefore the necessary basic equipment only includes a device to tie up the sheet, the tool type punzón and a system CNC (robot, fresadora) that moves the tool according to the path programmed. Depending on if it uses support or no and of the geometry to realizar exist different configurations of process, as it shows in the Figure 1. Like this, when the geometry is concave speaks of conformed negative, whereas if the geometry is convex the conformed is positive. On the other hand, when it does not use support the process designates Single Point Incremental Forming (SPIF) and if it uses support designates Two Point Incremental Forming (TPIF). When it works with a partial support combine SPIF and TPIF.

Although the technology finds still developing, exist already some industrial applications. AUDI Has an installation of conformed incremental robotizada in his centre of pre-series [1] in which they manufacture prototypes of structural components of the vehicle. On the other hand, Deep includes pieces manufactured by conformed incremental in his platform of vehicles customizable Modulate [2]. Specifically, of the model S800 manufactures the hood with the end that the buyer can customise the geometry to his taste. In the model Fit HB in addition to the hood also manufactures the guardabarros. Tecnalia works in the development of the conformed incremental from 8 years ago. It has coordinated two European projects SCULPTOR (FP6, ref. 14026) and INMA (FP7, ref. 266208) devoted to this technology and has elaborated studies of technical feasibility for different companies of the aeronautical sector component manufacturing sector component manufacturing sector and of the urban equipment. Recently, it has designed and set up a cell robotizada for the manufacture of pieces by means of this technology.

2. Identification of basic geometries

The first step of the experimental analysis of technical feasibility of the conformed incremental for the case posed Fagor Industrial consisted in carrying out a study of the geometrical characteristics of his pieces. The object of the study was to identify the geometries of basic type that define the pieces. For this, Fagor Industrial selected a group of pieces sufficiently representative of the pieces and families of pieces that compose his current catalogue of products. In total selected 13 pieces between which find components of pertaining products to his distinct sections such as the lavandería, the cooking or the ovens. The Figure 2 collects the images of the pieces selected.

Of the analysis of the pieces proposed Tecnalia identified the following basic geometries:

Embuticiones. Can present from walls with little inclination until vertical walls and can be of distinct forms (square, circulate, irregular). Depending on the piece considered the filling situates by the expensive sight or the no sight.Eyelashes. The eyelashes locate in the extremes of the pieces or around the holes. The eyelashes in the sides present a width of until 30mm and those that surround the holes can arrive to the 10 mm of width.Recess. recess Them, unlike the embuticiones present very little depth (underneath of the 5 mm). His walls are straight and his form varies a lot of a piece to another. According to cual was the piece considered the recess situates by the expensive sight or the no sight.Corners. In the embuticiones and recess them the resultant corners of the intersection between two walls present a radius (minimum 3 mm).Slots. Some pieces present embuticiones in shape of slot that characterise by a width and a depth reduced (10-15 mm of width and a depth roughly the same to the half of the width) in front of his length. His walls are vertical.alive Edges and radios of agreement. The pieces present alive edges and small radii of agreement (1-3 mm) in the intersection between the walls and the horizontal surfaces.Small personalizaciones. treats of other details such as lengüetas for the fixation of the piece to another component, marked of sheet, etc. Generally are not of big size and his geometry changes of a piece to another.

Can conclude therefore that the pieces proposed are defined from some basic geometries (8 in total) that according to the piece considered vary of dimensions, of number and in the form in which they combine ones with others.

3. Manufacture of the basic geometries

3.1. Experimentation

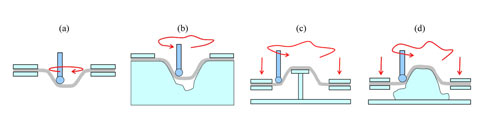

The proofs of conformed realizar in a machine developed internally by Tecnalia. It treats of a machine of structure type gantry that has of 5 axles. To tie up the sheet and the matrix used an also developed tooling internally and that allows to conform so much in positive as in negative. Besides, when it works with the positive configuration is possible to apply a pretence to the sheet. In the image of the Figure 3 can see the device used.

Like tools used different punchers of carbide of tungsten with diameters comprised between the 6 and the 20 mm. The geometry of these punchers adapted to the specific characteristics of each basic geometry. Like lubricante used an oil EP (900-960 cSt to 40 °C) to guarantee some good conditions of contact between the tool and the sheet. With the end to obtain the maximum geometrical precision, in all the proofs worked with a support mechanised in a resin of high density. Like conditions of operation fixed for all the proofs a speed of advance of 3.000 mm/min and a step of tool between turn and turn of 0,5 mm. Like material for the proofs used AISI 304, stainless steel austenítico employed by Fagor Industrial for the greater part of his sheet metal pieces. They used sheets so much of 400 x 400 mm as of 600 x 600 mm, all they of 1,0 mm of thickness. For the proofs that like this required it measured the thickness of the sheet with a measurer of ultrasonic thicknesses with a standard resolution of 0,01 mm. In some cases obtained also geometrical measures of the sheet (radios of agreement, angle formed between two walls…) by means of replies in resin of cured fast that later measured using a microscope of workshop.

3.2. Embuticiones

In the conformed incremental the sheet remains subject by his perimeter during the operation of conformed of such way that, in theory, the zone of sheet deformed is subjected exclusively to a deformation to cortadura. According to this, after the operation his thickness is inferior to the original in accordance with the expressesion known commonly like law of the breast:

Where t0 represents the initial thickness of the sheet, t1 the final thickness and α it is the angle of inclination of the sheet generated by the deformation.

Of the previous expressesion deduces that it is not possible to obtain vertical walls (to=90º) by means of conformed incremental as the resultant thickness would be zero. In the practice, the state of deformations of the sheet is more complex and the thickness adjusts to the previous expressesion of approximate form [3]. Like result, the break of the sheet owing to thicknesses too reduced produces enough before arriving to the 90º of inclination. By this reason, numerous works [4] have considered the manufacture of embuticiones with the end to identify the angle of wall limit although the results refer to aluminiums little aleados (series 1XXX) and common steels in tooling (DC04, DC05). In all the cases, the angle limit situates roughly between the 60-65º depending of the material and of the thickness considered.

In accordance with previous results obtained by Tecnalia, the value of the angle limit when shapeless incrementalmente AISI 304 of 1,0 mm of thickness situates in the 65º. Nevertheless, these results refer to sizes of piece quite more reduced that those that characterise the pieces of Fagor Industrial. To check the generality of the already existent results defined two geometries type of dimensions chords to the ones of the pieces proposed. Specifically, it treats of a trunk of cone of 450 mm of diameter (conformed negative) and a trunk of pyramid of base squared sideways 250 mm (conformed positive).

Both geometries present a height of wall of 100 mm because of restrictions in the volume of work of the tooling of tie up used. Each geometry manufactured 3 times to guarantee the repetitividad of the results.

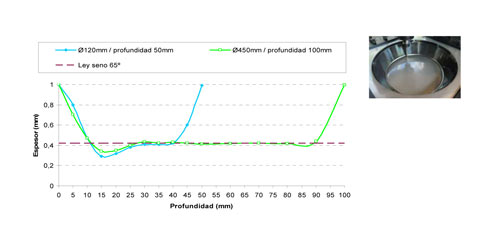

In the case of the trunk of cone conformed in negative the 3 pieces manufactured without problems. As it can appreciate in the Figure 4, the thickness presents the same distribution with independence of the size of the piece. This means that while it do not surpass the critical value of 65º the depth of filling is boundless.

Appears 4. distribution of thicknesses in pieces type trunk of cone with 65º of angle of wall. Each value of the thickness represented is result of the average of 4 measurements.

Instead, in the case of the trunk of pyramid conformed in positive 2 of the 3 pieces manufactured broke during the operation. The break produced in the two cases, as it can observe in the Figure 5, in a zone of the already conformed sheet. The conformed incremental characterises [5], [6] for inducing in the sheet a state of tensions practically uniaxial according to the vertical steering (descent of the tool) by what when a piece breaks presents a horizontal crack. In this case instead the apparition of a vertical crack suggests the existence of a state of twinaxial tensions that justifies the break with 65º of inclination. In this type of piece observed besides that the effect of the elastic recovery is evident to simple sight owed his big size, thing that no sucede when realizar pieces of size more reduced.

To surpass the limitation in the angle of wall Tecnalia has developed [7] a type of paths of tool with which is possible to realizar vertical walls, as it can see in the example of the Figure 6. However, it treats of strategies multietapa that cause the progressive hardening of the sheet. In accordance with the results of the proofs realizar, the maximum depth of filling in the case of the material considered situates in 30 mm.

3.3. Eyelashes

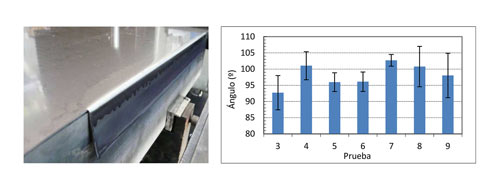

In the pieces proposed by Fagor Industrial are frequent so much the lateral eyelashes, that close the perimeter of the piece, as those that close the holes. In the case of the lateral eyelashes, after reviewing all the pieces proposed defined one like geometry of study an eyelash of 30 mm of wide representative of the most demanding case of the identified. After testing different paths and types of tool could observe , see the Figure 7, that the resultant angle is always upper to the 90º owing to the elastic recovery of the material. Nevertheless, the result varies slightly according to the type of tool and path used. As it can see in the graphic, in the most favourable case the half value situates underneath of the 95º with an interval of some 5º (tests Number 3). To delete the problem of the elastic recovery would be necessary to deform an upper angle to the 90º, which demands to use a machine of at least 4 axles (5 according to how was the geometry of the piece). Anyway, the lateral eyelashes do not represent a basic geometry criticism put that they can obtain in a plegadora of way very fast and economic.

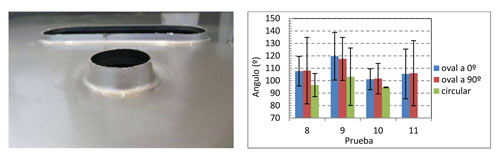

Regarding the eyelashes that close the holes, defined a circular eyelash of 12 mm of width and another oval of 7 mm corresponding to the most demanding cases (maximum width) present in the pieces. The eyelashes ovales realizar according to the steering of laminación and to 90º of the same to analyse his possible influence in the results. They used distinct paths of tool and geometries of tool following the recommendations of the bibliography [8] and the own experience of Tecnalia. To the equal that in the case of the lateral eyelashes, the elastic recovery showed by the eyelash varies according to the path of tool chosen, see the Figure 8. In the best of the cases (tests Number 10) the half value of the angle of bent situates in 95-100º with an interval of until some 10º as it treat of the eyelashes ovales or the circular. In any one of the cases, the steering of laminación does not seem to have any effect in the results.

3.4. You recess

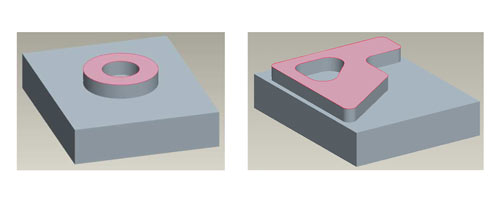

To analyse the possibility to realizar recess defined the geometries showed in the Figure 9. The circular geometry extracted of one of the pieces proposed. The another geometry is a geometry type that includes deformations to 0/45/90º of the steering of laminación combined with radios. The dimensions of the radii are also extracted of the pieces. Both geometries allow to obtain in an alone tied a recess by the face of the sheet in contact with the tool and another by the opposite face. Each geometry manufactured 3 times to guarantee the repetitividad of the results. The results obtained indicate that the sheet breaks of average to the 5,2 mm. It is possible therefore realizar recess them present in the pieces (walls of less than 5 mm of height).

3.5. Other basic geometries

In addition to the basic geometries commented in the subapartados previous the pieces proposed present details of lower scale. It treats , as already it has explained in the Apdo. 2, of corners, slots, alive edges or radios of agreement and small personalizaciones. These geometries result too small to obtain them using the dimensions of tool (of 10 to 25 mm of diameter) and geometries (hemispherical tip) with which usually works [4] to avoid well the fracture of the tool or the break of the sheet.

To analyse the possibility to obtain details extracted some geometries of study of the pieces proposed. They correspond to the most demanding cases (minimum dimensions) save in the case of the personalised detail where chose a detail at random from among all the showed by the pieces. The results obtained indicate, as it can appreciate in the Figure 10, thanks to a design of tool and to a suitable path is possible to produce details using the conformed incremental.

4. Analysis of technical feasibility of the manufacture of pieces

From the results obtained about the manufacture of basic geometries realizar an analysis of the technical feasibility to obtain by means of conformed incremental the pieces selected by Fagor Industrial.

To determine if a piece can manufacture or is not precise to identify and analyse separately each one of the basic geometries that contains. If the basic geometries can manufacture the piece also can manufacture. On the other hand, to the hour to analyse the manufacture of a piece by means of conformed incremental is necessary to define why side (expensive sight, no sight) goes to manufacture. The criterion adopted was to avoid in the measure of the possible the contact of the tool with zones seen of the piece with the end to guarantee an optimum superficial quality of the expensive sight of the piece. The Table 1 resume the results of the analysis.

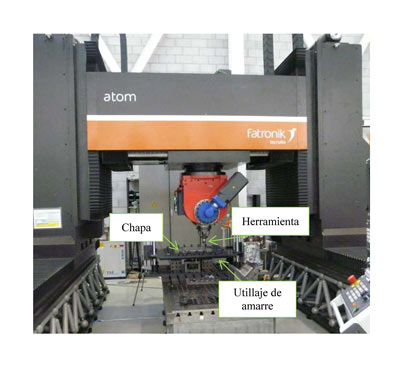

5. Manufacture of the piece demostrador

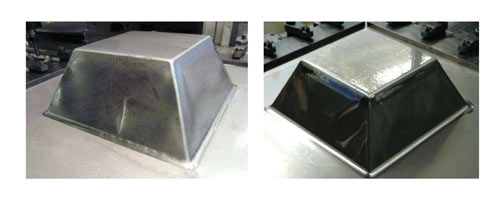

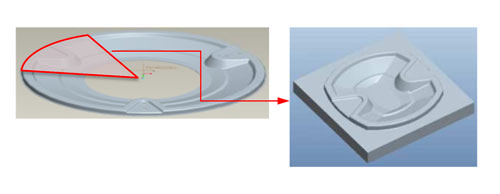

To confirm the analysis of technical feasibility of the pieces of Fagor Industrial in base to the basic geometries proceeded to the manufacture of a piece demostrador. Because of the limitations in the size of sheet of the tooling of tie up with which explains Tecnalia designed a piece demostrador from a to scale real portion of one of the pieces proposed. In the Figure 11 show the real piece and the demostrador.

The piece demostrador contains all the present basic geometries in the real piece and that in concrete are:

- Embutición Of walls to 60º and depth 41 mm by the expensive sight

- Embutición of walls to 90º and depth 11 mm by the face do not dress

- Radii of agreement of 1 mm

- Recess of 2 mm of depth

- Corners of radius 3 mm

Once designed the demostrador defined the sequence of operations of conformed necessary to produce each one of his basic geometries and as resulted the piece. After manufacturing the piece proceeded to cut it to check the effect of the release of residual tensions, see the Figure 12. The piece was contrasted by Fagor Industrial and has his seen well.

6. Conclusions

The present work collects the analysis of technical feasibility about the manufacture of components of sheet for industrial appliance by means of conformed incremental asymmetric that Tecnalia has realizar for Fagor Industrial. The results obtained show that the technology is capaza to manufacture the geometries of piece proposed except in the cases of embuticiones with walls of more than 65º of inclination and 30 mm of depth. Instead, if the inclination of the walls does not surpass the 65º does not exist limit in the depth of filling. It is necessary now confirm by means of the manufacture of real piece that do not exist problems associated to the effect scale (p.And. Deformation of the piece when cutting by the release of residual tensions). The implementation of a software that facilitate the programming of the paths of tool is another an indispensable element to facilitate the industrialisation of the technology.

References

[1] http://www.kuka.com/nl_media/07/text_inkrementelles_umformen_en.pdf

[2] http://world.honda.com/news/2005/4050112.html

[3] Young D. Et al., Wall thickness variations in single-point incremental forming, Proc. Instn. Mechn. Engrs., 218, Part B: Eng. Manufacture, 2004, 1453-1459

[4] Jeswiet J. Et al., Asymmetric single point incremental forming of sheet metal, CIRP 54/2/2005, 623-649

[5] Kim T.J. Et al., Improvement of formability for the incremental sheet metal forming process, Int. Journal of Siences, 42,

2000, 1271-1286

[6] Kim And.H. Et al., Effect of process parameters on formability in incremental forming of sheet metal, Journal of Materials Processing Technology, 130-131, 2002, 42-46

[7] Blond et al., Methodology to identify the suitability of new materials for Asymmetric Incremental Sheet Forming, iddrg 2011 Conf., Bilbao, 2011.

[8] Cui Z. Et al., Studies on hole-flanging process using multistage incremental forming, CIRP Journal of Manufacturing Science and Technology, vol. 2, no. 2, pp. 124–128, 2010.