Becker completes its range of side channel of high-speed equipment

July 9, 2010

A world of possibilities

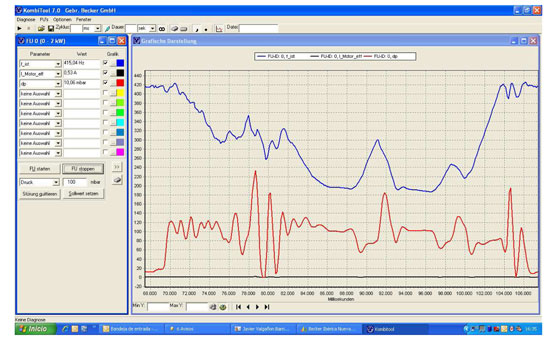

- Fixed frequency: the working point is transmitted to the VASF via an external signal, supplied by the user.

- Internal modulation: while maintaining a level of difference of pressure without external transformers. The level of difference of pressure to achieve is transmitted using an external signal. The internal setting of the VASF maintains the level indicated by automatically regulating the frequency of the engine.

- External modulation: while maintaining a level of difference of pressure in a given consumption point. The level of difference of pressure to achieve and the level of difference in the system are transmitted by means external to the VASF, which in turn signals and automatically regulates the frequency of the engine to reach the specified working point.

Communicate, carry out and report

-Analog input: connection to enter the frequency of the engine, work in vacuum / pressure, flow, connection of an external transformer,...

-Analog output: connection for the transmission of a point of work, for example, to work in Master/Slave. The following values can be passed: current frequency; vacuum / pressure; flow; engine consumption; power engine; present value in analog input; etc.

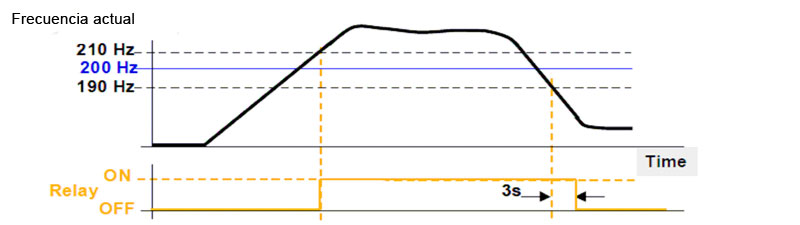

-Relay: This relay provides a series of signals that have to be transmitted to a State prederteminado. Functions as well as the conditions of drive are parameterized previously at Becker facilities or at home of the client. Basis, the relay provides the following functions: collective failure message; posts by collective work; overweight of limit values, it is possible to introduce a hysteresis and a delay in the starting and stopping; Active consumption limit; Active temperature limit; continuous deviation of values; and extent of the value.

Clean air, exact supply

One of the great challenges of our time is the production of clean energy for the protection of our environment. The different production processes include the recovery of solar energy in organic waste from agriculture and animal husbandry, linked through biogas plants.

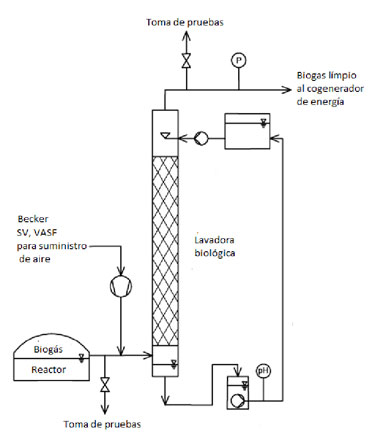

Before the biogas can be used to generate electricity or thermal energy, it is necessary to purify it through the processes of desulphurisation, drying and separation of gases.

The desulfurization is the oxidation of hydrogen sulfide included in biogas to keep the concentration of this gas below the levels suggested for final use. To this end the major manufacturers of biogas plants rely exact air supply Becker, including VASF systems through side channel compressors. This method of desulfurization in addition to being cheaper than others, provides sulfur to the leftovers of the biomass and thus increases their quality as fertilizer.

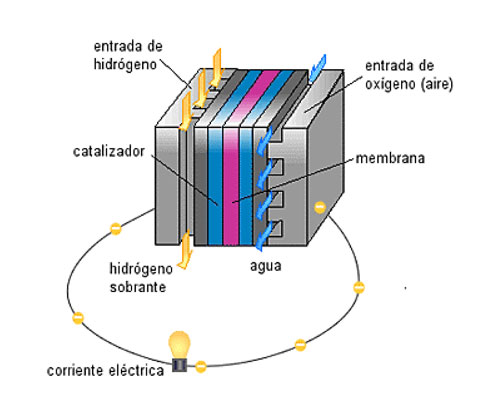

One of the great challenges of our day is the generation of clean energy and which is obtained by the fuel cells.

Fuel cells are an electrochemical device that converts the energy released in the reaction between a fuel (usually hydrogen) element and an oxidizing agent (oxygen) into electrical energy. The fuel cell consists of two electrodes (anode and cathode) separated by a Proton conductive membrane.

Provided hydrogen dissociates in protons and electrons. The electrons are driven through the anode, producing energy, while the protons pass through the conductive membrane. At the cathode, oxygen molecules are reduced by the dissociated electrons of the hydrogen and become anions. The subsequent reaction between anions and cations is water.

The simplified electrochemical reaction is:

2 H2 + 02 = 2 H2or + color + electricity

While the quality and purity of the hydrogen are of great importance to the good performance of the fuel cell, the oxygen comes from the ambient air. By systems VASF is achieved through a driving of oxygen controlled and effective, while respecting and serving as variable parameters as important such as flow, pressure level and response time to the needs of the cell. All this with an integrated system sometimes requires no more than 10% of the energy generated by the same stack.