Súper-estructurales materials: a step towards the replacement of metals

June 3, 2009

The LVL company has introduced new grades of special materials, which may be deemed "a true reference in most structural applications". Thus, the company offers compounds designed to achieve an optimal load and the best module of elasticity, according to the requirements of a project. In this way, engineers can correct operations of design from the beginning, when it requires a proper replacement for metals. You can avoid certain unfavourable commitments, such as the use of composites or inserts, metal components and assemblies.

In addition, the wide range of thermoplastic compounds LVL also allows select appropriate resin for an adequate solution of the environmental factors most critical, since high temperatures up to chemical attacks, through exposure to moisture, and inclement weather.

High module materials

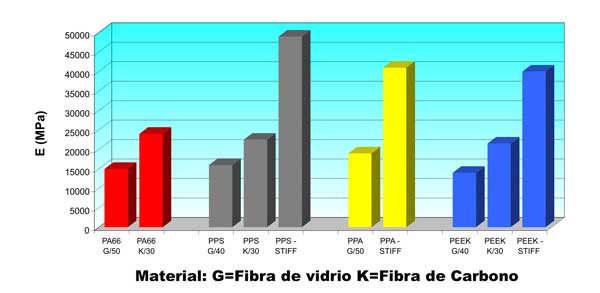

High module materials are a new branch of compounds that offer a modulus of elasticity outstanding, almost twice the value of products with fibres and carbon. These formulations are designed to strengthen the thermoplastic matrix with fibers of carbon of high load, such as those used in the aerospace industry. The resulting materials can create pieces with low deformation under load.

For these reasons, the ultra-rígidos materials are ideal candidates for replacement of composites and metal alloys in applications where their employment is plan based on non-deformation, more that on the basis of the high load or stiffness.

A composed virtually not deformable can fit perfectly in various industrial sectors where required the use of pieces with low dimensional geometric tolerances such as aerospace, mechanisms of precision, electronics, textile, military, pneumatic machinery and special valves. Ultra-rígidos materials are provided exclusively in high-performance resins: PPA, PPS, PEEK and PAs.

Materials of high load breaking

Metals are often used where you expect heavy mechanical stress, such as cutting, bending and torsion. The ability to withstand very high loads is part of the proposal of LVL, achievable through the use of reinforced materials with high content of glass fibers.

The best proposals are based on compounds of PA6, PA66 and PPS reinforced with 40, 50 or 60% of glass fibres. These products are characterized by an interesting relationship benefit/cost. Nevertheless, the polyamides show problems related to humidity and high temperatures, and PPS is constrained by its well known small elongation in the breaking point. To overcome these disadvantages, LVL has introduced the Laramid G/60, a PPA degree base strengthened with 60% of special glass fibers with high mechanical resistance.

Laramid G/60 is able to reach a burden to the rupture of 280 MPa, which has a resistance 25% larger than a common compound of PA66 with the same wording, and 40% higher than similar degrees based on PPS. In addition, outstanding elongation shows the capacity of the compound to withstand deformations without reaching the yield strength. One interesting application is the accessories of pipelines and structures.

Also, base resins offer unique advantages such as its low moisture absorption, high chemical inertia against organic products, as well as with the majority of acids and bases, very high thermal performance, allowing the compound to withstand continuous temperatures of 150 ° C without changes.

For these reasons, Laramid G/60 is "the best candidate to replace the aluminium and its alloys, steel or bronze in the manufacture of accessories for piping or parts under the hood, in the field of automobile, among others".

Structural materials with improved aesthetics

Today, more and more extreme mechanical applications require an improved aesthetic of the molded part. For this reason, LVL has introduced a range of structural compounds made to measure called Latigloss, its peculiarity is a special formulation that allows to obtain parts with shine and without surface defects.

Latigloss are compounds based on PA6 and PA66 reinforced with 30-60% of 30% of fibres of carbon or glass fibre, characterized by outstanding mechanical properties that do not generate marks of fibers in the surface normal materials reinforced normal.

Materials with good surface finish, but also with high dimensional stability, thanks to its good and homogeneous contraction are not only achieved with Latigloss. In addition, the company has special versions with a behavior improved flame and, soon, degrees for applications in contact with food and water.

The surface termination that can be obtained with these materials allows to compare the Latigloss with products of high performance. The appearance is, in fact, perfectly regular in the coloured versions. Low roughness offers best landslides to move the pieces, but, above all, gives the opportunity to avoid the aesthetic optimization of parts moulded as a painting, metallization or subsequent to the moulding techniques.

As a result, certain degrees of Latigloss are suitable for embellishment post manufacturing processes, as shown in the chrome parts of the image.

The correct balance between mechanical, thermal and aesthetic properties, good dimensional stability and ease of process, make the family materials Latigloss "a perfect substitute of more expensive compounds, such as semi-aromáticas polyamides or mixtures similar, especially frequent in molding processes simple and cheap".