Branson Ultrasonidos, S.A.E. - Plastic welding machines

Branson

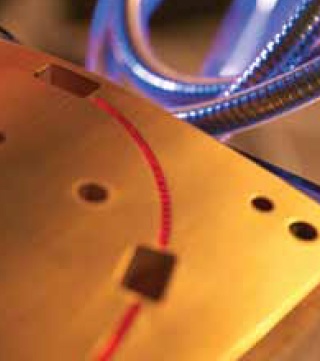

Infrared welding: assembly non-contact procedure

The infrared welding it is a non-contact Assembly procedure, in which areas of welding of the parts to be bonded are fused by heat of radiation that are provided by go wave radiators long sheet metal and that adapt to the contours of the parts. This provides greater freedom of creation, for example with parts with interior walls and curved welding areas. The procedure provides strong, watertight weldings outdoor with a homogeneous and solid edge and with a very good quality of expulsion.

Compatible with the majority of thermoplastics, the infrared welding is suitable especially for temperatures higher manufacturing and usable with semi-crystalline plastics such as polyethylene and polypropylene. The infrared heat source can be controlled with precision, which is important when parts are sensitive to heat.

Compatible with the majority of thermoplastics, the infrared welding is suitable especially for temperatures higher manufacturing and usable with semi-crystalline plastics such as polyethylene and polypropylene. The infrared heat source can be controlled with precision, which is important when parts are sensitive to heat.