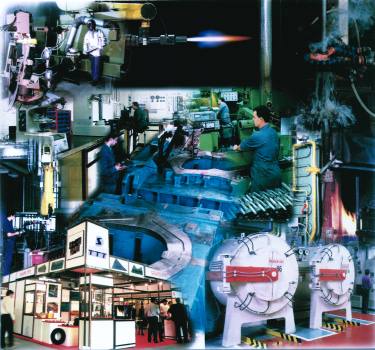

Grupo TTT de Tecnologías Integradas de Superficies, S.A. - Thermal treatment service

Heat treatments: for the aeronautical sector

The TTT group, within the wide range of heat treatment applied, has several whose scope is the aeronautics sector.

In their treatments in high vacuum, heating is done by radiation of slow and progressive reaching temperatures of up to 1,250 ° and levels of 0,0001 mbar vacuum. According to the material to be treated, warm oil, vacuum or overpressure nitrogen can be made. The treatment in vacuum, allows to obtain clean and unalterable surface chemical composition and therefore carry out treatments of totally finished parts.

'nitreg' nitriding is a gaseous nitriding of latest generation whose success lies in the nitriding potential control, which allows to get layers to the letter. The variant 'nitreg-onc' consists of a nitrocarburizing with oxidation and the Nitreg-'s ' is a specific process for nitriding with high speed steel. Depending on the application, the different layers that can be obtained will allow improving the wear resistance, corrosion resistance, thermal fatigue and the coefficient of friction.

The projection by plasma is a thermal projection which allows to apply ceramic coverings on any type of metal components without warming of these. The surface finish of the parts varies according to the needs of the client.

The projection by HVOF meanwhile is a thermal projection at high speed, using high kinetic energy released game, seeking extreme grip and density coatings capable of withstanding wear by abrasion, erosion and impact up to temperatures above 850 °.

In their treatments in high vacuum, heating is done by radiation of slow and progressive reaching temperatures of up to 1,250 ° and levels of 0,0001 mbar vacuum. According to the material to be treated, warm oil, vacuum or overpressure nitrogen can be made. The treatment in vacuum, allows to obtain clean and unalterable surface chemical composition and therefore carry out treatments of totally finished parts.

'nitreg' nitriding is a gaseous nitriding of latest generation whose success lies in the nitriding potential control, which allows to get layers to the letter. The variant 'nitreg-onc' consists of a nitrocarburizing with oxidation and the Nitreg-'s ' is a specific process for nitriding with high speed steel. Depending on the application, the different layers that can be obtained will allow improving the wear resistance, corrosion resistance, thermal fatigue and the coefficient of friction.

The projection by plasma is a thermal projection which allows to apply ceramic coverings on any type of metal components without warming of these. The surface finish of the parts varies according to the needs of the client.

The projection by HVOF meanwhile is a thermal projection at high speed, using high kinetic energy released game, seeking extreme grip and density coatings capable of withstanding wear by abrasion, erosion and impact up to temperatures above 850 °.