Hasco Ibérica Normalizados, S.L.U. - Other complementary equipment for moulding

Hasco Z457/... y Z/4651

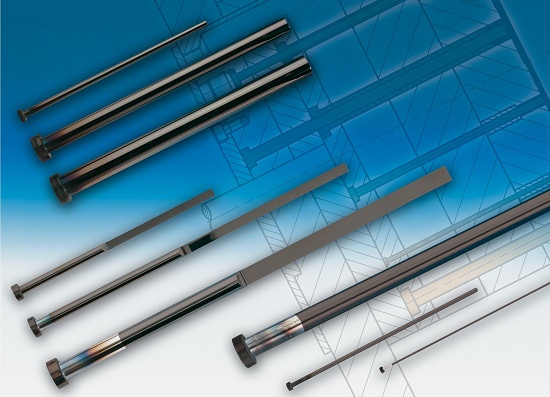

Ejectors: ejector sleeve and flat ejector pin with DLC coating

Ejectors are some of the parts that are subject to the most stress in the mould. With its extensive range of ejector elements and numerous combination options for ejector pins and sleeves, either with or without a coating, Hasco offers individually-tailored solutions for functional component removal from injection, compression moulding and die-casting moulds.

Hasco's versatile standard range of hardened, nitrided and plasma-nitrided ejector elements has now been extended by Z4651/... DLC-coated flat ejector pins with two corner radii and Z457/... standard sleeves. The advantages of the DLC coating can now be used to the full by combining the new sleeves with the Z400/... ejector pins that are already available.

The DLC coating combines a high hardness with the very best tribological properties, thus keeping friction and wear down to a minimum. The new ejector pins and sleeves are especially suited to use in the food and medical sectors, since production can be run without lubricants, making it compatible with a clean room environment. The high coating hardness and the low coefficient of friction of the coated ejector sleeves in combination with the DLC-coated ejector pins clearly improves the mould service life and thus contributes towards boosting mould productivity.

The use of DLC-coated demoulding aids has a positive impact on component quality, improves the operation of the mould and hence also optimises the production process. In addition to the standard ejector range, HASCO also offers customised versions for specific applications.

Hasco's versatile standard range of hardened, nitrided and plasma-nitrided ejector elements has now been extended by Z4651/... DLC-coated flat ejector pins with two corner radii and Z457/... standard sleeves. The advantages of the DLC coating can now be used to the full by combining the new sleeves with the Z400/... ejector pins that are already available.

The DLC coating combines a high hardness with the very best tribological properties, thus keeping friction and wear down to a minimum. The new ejector pins and sleeves are especially suited to use in the food and medical sectors, since production can be run without lubricants, making it compatible with a clean room environment. The high coating hardness and the low coefficient of friction of the coated ejector sleeves in combination with the DLC-coated ejector pins clearly improves the mould service life and thus contributes towards boosting mould productivity.

The use of DLC-coated demoulding aids has a positive impact on component quality, improves the operation of the mould and hence also optimises the production process. In addition to the standard ejector range, HASCO also offers customised versions for specific applications.