Redex Spain, S.L. - Other machine tool accessories

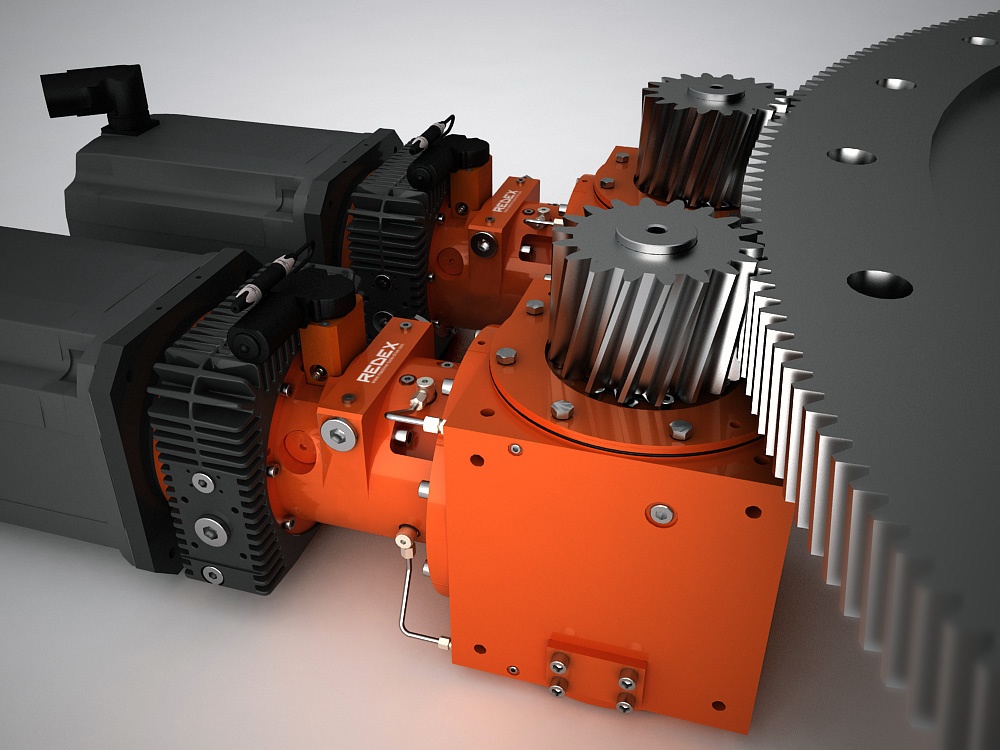

Redex MSR

Drives for torneado-fresado tables: they offer significant reductions of cost in design and Assembly

The range of drives MSR Redex is a turnkey solution for tables of torneado-fresado, which offers important machine tool manufacturers in design and Assembly cost reductions. The functions of turning and C-axis are implemented in this same drive, making the most compact machine, at a time which is substantially improved performance, accuracy and maintenance.

MSR drives radically simplify the kinematics of the mechanical transmission on vertical lathes, large size, avoiding intermediate stages between the engine and the Crown. Redex TwinDrive configuration consists of two cases of transmission with identical engines. It is a standard, economic solution and greater availability than a single large engine. In operations of turning share the torque to 50%. With the help of CNC, managed a system master-slave that eliminates 100% of the slack when it acts in "C-axis" mode, and can carry out the work of interpolation and most demanding positioning (milling, drilling, reaming, etc). I.e., there are function turning and positioned in a same drive without auxiliary components.

Machinery fabricators multitask (multitasking) so have a solution commercial, exclusively available by Redex, for dishes of torneado-fresado of high-performance drives, compatible with the latest generations of controls and commercial regulators (Siemens, Fanuc, etc).

Benefits of the MSR range cover any market need: - four sizes available - up to 9.000/18.000 (2 x 100 kW engines) Nm output torque.

-Global reduction relations (including box + Crown gear): 172/45 and 77/20.

-Pairs in the table up to 270,000 Nm - only angular forwarding option.

MSR drives radically simplify the kinematics of the mechanical transmission on vertical lathes, large size, avoiding intermediate stages between the engine and the Crown. Redex TwinDrive configuration consists of two cases of transmission with identical engines. It is a standard, economic solution and greater availability than a single large engine. In operations of turning share the torque to 50%. With the help of CNC, managed a system master-slave that eliminates 100% of the slack when it acts in "C-axis" mode, and can carry out the work of interpolation and most demanding positioning (milling, drilling, reaming, etc). I.e., there are function turning and positioned in a same drive without auxiliary components.

Machinery fabricators multitask (multitasking) so have a solution commercial, exclusively available by Redex, for dishes of torneado-fresado of high-performance drives, compatible with the latest generations of controls and commercial regulators (Siemens, Fanuc, etc).

Benefits of the MSR range cover any market need: - four sizes available - up to 9.000/18.000 (2 x 100 kW engines) Nm output torque.

-Global reduction relations (including box + Crown gear): 172/45 and 77/20.

-Pairs in the table up to 270,000 Nm - only angular forwarding option.