Redex Spain, S.L. - Speed regulators

Redex DRP

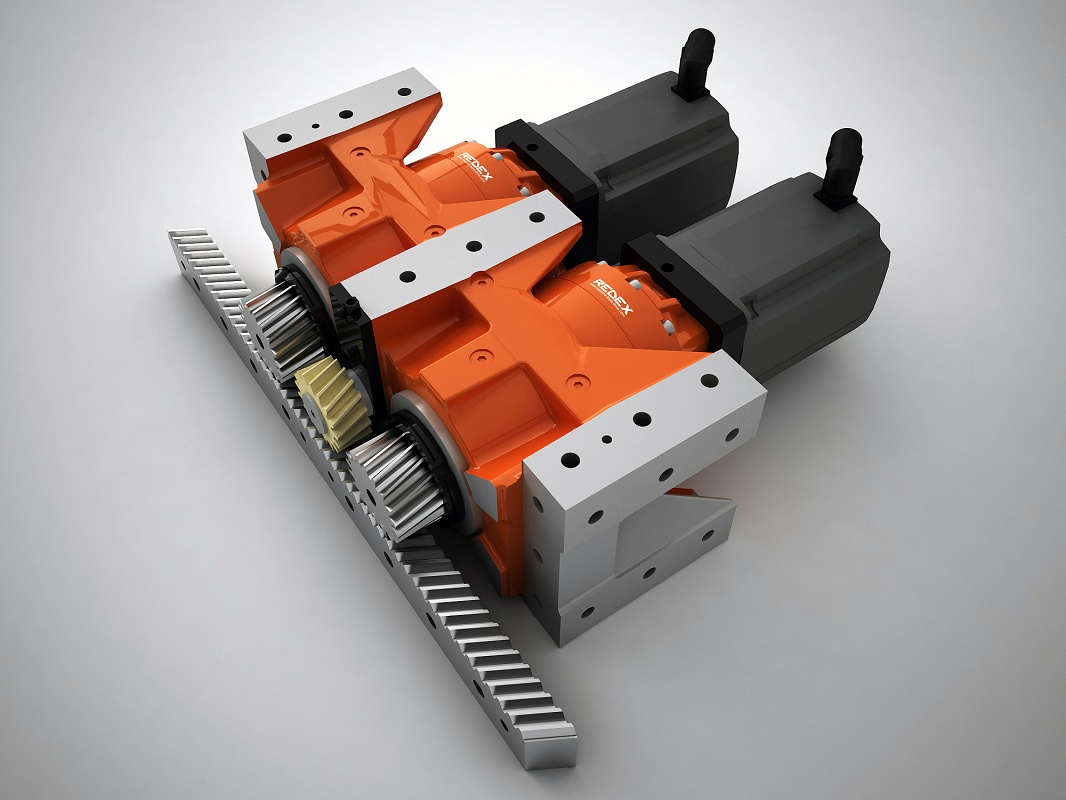

Cubic concept for rack and pinion drives: range consisting of 5 sizes of planetary gearboxes high rigidity and low game

With an eye on costs and other benefits, most of the leading manufacturers of machine tools have become a "cubic concept" invented and developed by Redex to improve axle drives solutions.

The "cubic concept" implies that the structure of the machine where the gearbox is mounted becomes part of the drive itself. Unneeded intermediate pieces between reducer and machine and, on many occasions, it avoids the need to extend the truck where it is mounted. The implementation of the single mounting requires simple machining of a flat surface to fit the reducer mounting interface. The main objective is to save design and Assembly costs and substantially improve rigidity.

The DRPng range consists of 5 sizes of gearboxes planetary of low game and high rigidity, fully integrated in a cubic enclosure ready to be mounted on machine as part of its own structure.

Redex DualDrive system allows cancellation of 100% of the game throughout the system rack and pinion via a profitable mechanical pre-charge with single-engine layout. Also you can have a system of cancellation of the game using the function master slave of electrical preload using two engines (Redex TwinDrive system).

The patented solution of Redex carving in the same output shaft sprocket, offers the ideal combination of transmissible torque and linear stiffness. The package of bearings that support the output pinion consists of two preloaded and notably oversized angular contact roller bearings. This construction allows supporting point to be as closely as possible to the point of load on the engine, since only the thickness of the preload nut separates the pinion bearings Pack. This unique design greatly reduces radial flexion, which is responsible for 60% of the total distortion, which tends to be the weak point of the majority of existing systems on the market.

Thus, the natural frequencies of the shaft drives that incorporate the DRPng increase significantly, having the machine of high KV levels that allow greater Dynamics (up to 25 m/s2) without need to implement electronic filters. The result is a greater ability to move heavier loads at a higher rate in the most demanding requirements of position.

The "cubic concept" implies that the structure of the machine where the gearbox is mounted becomes part of the drive itself. Unneeded intermediate pieces between reducer and machine and, on many occasions, it avoids the need to extend the truck where it is mounted. The implementation of the single mounting requires simple machining of a flat surface to fit the reducer mounting interface. The main objective is to save design and Assembly costs and substantially improve rigidity.

The DRPng range consists of 5 sizes of gearboxes planetary of low game and high rigidity, fully integrated in a cubic enclosure ready to be mounted on machine as part of its own structure.

Redex DualDrive system allows cancellation of 100% of the game throughout the system rack and pinion via a profitable mechanical pre-charge with single-engine layout. Also you can have a system of cancellation of the game using the function master slave of electrical preload using two engines (Redex TwinDrive system).

The patented solution of Redex carving in the same output shaft sprocket, offers the ideal combination of transmissible torque and linear stiffness. The package of bearings that support the output pinion consists of two preloaded and notably oversized angular contact roller bearings. This construction allows supporting point to be as closely as possible to the point of load on the engine, since only the thickness of the preload nut separates the pinion bearings Pack. This unique design greatly reduces radial flexion, which is responsible for 60% of the total distortion, which tends to be the weak point of the majority of existing systems on the market.

Thus, the natural frequencies of the shaft drives that incorporate the DRPng increase significantly, having the machine of high KV levels that allow greater Dynamics (up to 25 m/s2) without need to implement electronic filters. The result is a greater ability to move heavier loads at a higher rate in the most demanding requirements of position.