New products presented by the machinery of production European, S.L. company

Mecof

The new vertical milling premium model with linear motors are presented with all the options available, including the new Twin head with continuous positioning. The premium range will be completed with large solutions from the 165 Airone and Airone 220.

Premiums and Airone represent the State of art of a technology of linear motors, which together with a wide range of electro-husillos and options, carry out tests of various materials with high dynamic machining.

The accurate line of high speed milling machines was released in the EMO with three versions: accurate CSX (mobile column), Precisa MX (fixed bed and mobile column) and accurate (fixed bed and mobile column) MZX. Accurate series is mainly dedicated to the machining of precision, where power, dynamics and Thermo-symmetrical structure are required.

During the fair Mecof also presented the new heads of milling recently developed by the company. In addition, the system B.R.A Wonder, which is capable of eliminating deviations from the RAM in the horizontal machines, with routes up to 1,500 mm.

Another important event for the Mecof group is the presentation of the new company Mecof GM, company that will manufacture machines of large dimensions for applications in General engineers, energy and industrial of the mold. Have presented models: FAMM: drilling machine and milling with mobile column, travelled vertically up to 6,000 mm, PML: milling machine gantry with planks on the sides of the table, FAQ: milling machine gantry with fixed structural support and mobile table and PMM: milling machine gantry with support (adjustable in height with an appropriate system) mobile structure.

Salvadeo Srl, Member of the Group Mecof, specializing in the buying and selling of second-hand and rebuilt machines (electric, electronic, mechanical part) machines took part in the show where he presented the best opportunities available.

In the field of design of PLM Solutions and software, is welcomed to Spaziosystem Spa, which introduced the new Matra Datavision. During the EMO, we saw the new CatiaV5/Enovia/Smarteam and all products PLM, with demonstrations based on Catia V5 Manufacturing.

Saporiti

Somex

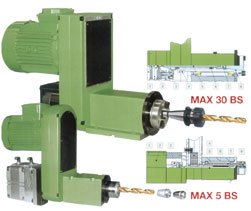

Head top-break revolver ETR 36 6 spindles, particularly compact and robust construction, has been designed to be implemented in advance UA5 unit, or the module 3 axes CNC Triax 4 PB 36 base plate. Integrates a spindle cone HSK 50 porta-herramientas and has options of lubrication centro-husillo, another servo motor, another type of spindle adaptor for multi-spindle heads, and forwarding of angle.

On the other hand, it introduced the module 3-axis CNC Triax 4 on which it can be implemented in the Z axis a rotating spindle type Max 45B or a head revolver ETR 36, it is in fact a Centre for machining 3-axis Cnc numerical control autonomous in optimal performanceprecise and small. Caucus, the bandwagon and support stabilized cast are strong section and extensively ribbed. These components are mounted roller of roller, greased for life and preloaded ball spindles of high precision and reliability. By Triax 4 support can be implemented in an upright position to the horizontal. Among their options include centralised greasing of ball spindles.

Machining unit Max 5 BS is equipped with a system of clamp ER25 porta-herramientas integrated in the spindle. Fixing strength is developed by the packing of disk of elastic washers. The unblocking of the system of the gripper is performed by a pneumatic cylinder's short career. Max 30 BS unit enables the quick-change system porta - tools ISO 40, based on the same principle as the drive Max 5BS by adding a double pneumatic cylinder.

In addition, Somex unveiled the unity of threaded autonomous, programmable type Max 12T, with an electronic speed variation, a time of reduced cycle of less than 2 seconds, without change of spindle pattern and high cutting speed. Integrates a control box Somex for control of the engine and the system of advances, with the variable frequency drive added, entries of data using a PC or adapted control, two connections by 5 meters of cables supplied, connected to the Toolbox control Somex and only one source of energy: tension 230 volts. Step modifications are simple and economic are made through the change of toothed pulleys. All the steps are achievable from 0.2 to 1.75 mm. Programming mode allows to enter the data for: start position, the beginning of the screw, the length of the screw, the speed of rotation of the male and the fast runs. The unit of threaded Center is the differential system.

The position of the cutting tool is directed and controlled by a linear potentiometer and the in-depth of threaded as well as their positions can be modified in each cycle. The engine, according to the ISO standards, is coupled to a variable drive speeds; You can be implanted rat or behind. It has a carte de transmission adjustable to 360 °.

Röders

Trevisan

All guides of the axes are equipped with a crossed ball roller and the cinematics of movement mechanisms consist of husillos of preloaded double spiral debolas recirculation and engine type Bruschless. All the mechanical elements plate turning sound of robust construction to ensure the machining with high extraction of chips. All movements are controlled to CNC. During the phase of checked the tool works in their best conditions with continuous Court program. Cane spindle (E) comes out from underneath the plate of turning (A), only when it last is blocked. The rotary table of 360,000 divisions in continuous, is equipped with lanes and links the pallet carrying equipment.

Sauter

Another innovation that launched to the international market has been the technology of axis (b), the complete machining with a single tool that increases accuracy and reduces non-productive times. Increases productivity thanks to the high-performance turning and milling of complex parts and also runs the milling also during rotation. Compact spindle has big benefits: configured for a fast and automatic tool change (HSK or capture), skilled exceptional charge for the operations of milling operations, through the blockade with teeth Hirth, a mñinima possibility of collision (only a tool) and extension of the term due to the controlled load of the bearing. The unit of rotation without game allows a high precision positioning in continuous by AC servo motor and gear gear preloaded (210 degrees rotation angle); lock position of spindle with teeth Hirth in increase of 5 degrees (precision of repetition ± 0,0008 mm), and you get a precise machining of the outline required through a system of measurement of angle.

The turret of Crown for tools, was also submitted by Sauter, which brings a high benefit in machining for transfer machines and special. The turret of Crowns is designed to improve productivity: with up to 8 individual tools or head of multiple spindle, the rapid employment of sophisticated tools, with total flexibility through programming of spindle. Some of the advantages are. Requires a single AC servomotor for the indexing of the turret and the tool drive; locking and unlocking of the revolver times can be arranged in parallel in the course of the Guide; the chance of collision with the "Crown" provision of tools; It is suitable for the operations of milling and drill, speed of spindle up to 18,000 pm, super-fast switching, resistance to shocks in the rotation, due to the limiting Board of labour; large series production and the porta tools not rises during indexing, because the teeth of circular zipper.

Rollomatic

The GrinSmart 620XS is a centre of grinding of precision to 6-axis fully automated CNC, destined to the production, in a setting of Rotary cutting tools in hard metal, high speed steel (HSS) or any other material. Extending the range of diameters from Ø 0.1 mm to Ø 16.0 mm Conception system only "offline" tools, equipped with high precision functions, is possible to produce all kinds of tools, equipped with high precision functions, it is possible to produce all kinds of tools ranging from strawberries to drill bits, passing through reamers, staggered and shape and other tools files swivel female employees in the sector medical in small or large series with the same effectiveness. 2-Axis CNC high-speed (65 m/min) robot can produce up to 1,000 pieces with a minimum of human intervention. It is possible to automatically switch the tools of total length 300 mm.

The unique concepts of maintenance of the tool, such as the guidance of the handle of the tool through a centering device, the support from court and others V allow the production of tools can quality and superior reliability. Grindsmart 620XS is delivered with the with the set of programs Rollomatic mainly the powerful 3D Simulator, the integrated robot. The user obtains thus a return on your investment with a quality high in a short period of time.