Energetic efficiency and compact solutions

10 May 2012

“Especially in the automotive sector notice an additional increase of the importance of the thermoplastic elastomers and also a general increase of his use. With our compact solutions and energetically efficient treat to do justice simultaneously to both worlds and establish standard in the injection by moldeo and in the vulcanización”, affirms Rudolf Eisenhuber, director of the Technical Area of Maplan.

Vertical machines with high repetibilidad

The MTF400/100 Edition S has a unit of injection of high precision Fifo with a volume of dosage of 400 cm3 guarantees a precision of upper dosage and a relation L/D constant. A very short filter provides maximum pressesure of injection directly on the mould. Besides, when being refrigerada, no precise withdraw. In the practice the unit plastificadora extensible simplifies noticeably each change of material. The series Edition optimised offers a high performance in a space reduced thanks to the surface of support with which explains, of only 2,3 m², and to that likewise the surface of subjection has been expanded in 20%.

But the most notable is definitely his level of energetic efficiency: the controls servo-hydraulics Cool-Drive II, that already formed part of the equipment of series of the version S, make possible that it reach an energetic saving of until 70% regarding other controls of conventional machines. And also the level of noise of this concept of accionamiento marks new standards. The version of the atemperadores DCI with energetic saving provide an atemperación optimum of the mould during all the cycle. Besides, the machine has of the system Cure², only to attain the optimisation of the process when reducing drastically the time of warming. It cure² analyse and it optimises for the user all the fundamental parameters of the process: atemperación of the mould, temperature of the cold channel, temperature of the cylinder of plastification, pressesure, contrapresión and revolutions of the husillo. And with this obtains an identical quality of the piece moldeada. The new characteristics of the device of control of the machine PC5000touch V3 will show in Nuremberg. “We are proud of our control, and no only by his interface Cure². In general it is very transparent and simple to use”.

Between his new characteristics find : the multimedia support, the new diagnostic on line, the function of cleaning, the additional statistical functions. It makes possible the execution of an optimum diagnostic. Ours last version aúna the precision with the high repetibilidad, “what does that the process with a machine Maplan was absolutely sure”, explains in this regard Rudolf Eisenhuber. Only it remains to mention the application: a piece manufactured with an elastomer fotoluminiscente of last generation. The prime matter from Beele Engineering, Aalten (NL), possesses a persistence lumínica of several hours. This material results interesting for elements of hygiene, objects for fast orientation or even from the point of view of the design.

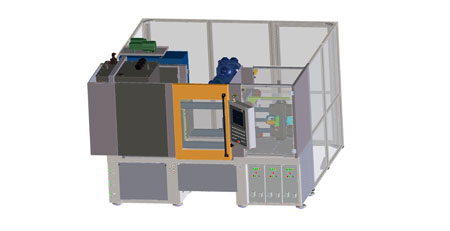

Automation of inyectoras for elastomers taking like example the horizontal machine 200 to Edition

The model MHF400/200 Edition puts of self-evident the subject of the automation with a robot of six axles. In general, a robot of 6 axles for the transformation of elastomers is rather little frequent up to now, admits Rudolf Eisenhuber. “To measure that increases the quantity of cavities or the complexity, the subject puts more interesting. Anyway, in the automation of finishings with elastomers exists still a potential height. Another contribution to the consolidation of the level of the production in Europe”. The model MHF400/200 Edition also finds instrumented with the newest technology of control PC500touch V3 with interface Cure². In this case it uses also a unit of injection of high precision Fifo, but here has of horizontal way. This gives like result a busy space of 3,6 m² without considering the mechanisms of desmoldeo. They manufacture bangles of rubber of silicone. The mould of injection with cold channels supplies it RO-RA Aviation Systems, of Schörfling am Attersee (Austria). The mould has a channel of cooling of double entrance puntiforme actively regulated with two cavities. Like robot of extraction equipment equipment employs a Fanuc M710iC/50And of 6 axles, with harp of RO-RA. The cell of manufacture works of way entirely automatic, without leaving rebabas and without need of mechanised back.

Vulcanización And revestimiento of finals of last generation

Maplan Develops also the model MTTF100/40C with freamers in shape of C. It treats of a machine inyectora vertical for elastomers, with upper closing. The freamers in C without columns characterise by an enormous rigidity of forms. The machines Maplan with freamers in C offer ergonomic advantages and of manipulation: they allow to the operator a free access to the space of setting of the moulds. The machines of this type are done for the vulcanización of finals, the encapsulamiento of glasses, for insulating elements, pieces of mould, caps or pieces of 2 K. There is available an alternative to the vulcanización, a version TPE in shape of unit inyectora valid for thermoplastic.