They motan will be exhibiting at Fakuma and Powtech its product enhancements

September 20, 2011

The number of generators of dry air and proven performance, 250 to 2400 m3/h expanded with three new measures: 80, 120 and 160 Luxor models. With these new teams, the range has ten models and all of them designed for centralized all kinds of plastic granules drying; in particular, for high-end materials and plastics engineering in sizes of batches that are changed frequently. New features have been added as the transport of up to 16 containers of drying and 24 wheel loaders material for machines. Also, you can use up to three transport blowers. Any of these advanced versions may incorporate all systems drying on drums offered by Motan. In addition, these series of 100 at 2,400 liters drying drums have expanded with the drums of the LBA system, with a capacity of 15, 30 and 60 litres. As well as higher volume models, they are equipped with all the basic options.

Luxor 80/120/160 models have been updated to obtain an advanced version with the addition of a dual circuit with two blowers and a system of closed-circuit heat regeneration process. On the other hand, the inclusion of pneumatic valves improves the stability of the process. Luxor 80, 120 and 160 models generate 80, 120 and 160 m3/h of dry air with a point of constant dew up to - 40 ° c. Molecular sieve cartridges installed function as an alternative. In this way, gets a provision, continuous and assured of uniformly dry material for processing machines. The three new models were designed to achieve a maximum capacity of up to 70/100/140 kg/h of material.

In Motan ensure that his users have confirmed that this technology offers a stable management of the process, a minimum use of energy and a process of dried that it does not see affected by the air of the environment. Of this form, "the mark can guarantee the best results of dried, even in tropical climates. These characteristics satisfy the increasing demand of technology of processing of advanced in the sector of the small dryers. With these models, attains the simultaneous processing of a variety of prime matters of high degree or the fast changes of material of sustainable way. They do not exist time of arrest and is not necessary to expect by the prime matters that have to process ", they affirm.

In this small system, the package of saving of energy ETA plus puts in operation for the dried of materials. In this case, the function of organisation/organization of dried combines with the control of the flow of air. The quantity of air of the process and the adjust of the temperature of dried control of analog form according to the needs of energy of the capacity of treatment of the material. ETA plus avoids the dried in excess or insufficient and guarantees the maximum quality of dried possible of the granules with minimum levels of residual humidity. If it compares them to him with the conventional dryers, now is possible to attain a reduction of the consumption of upper energy to 60%.

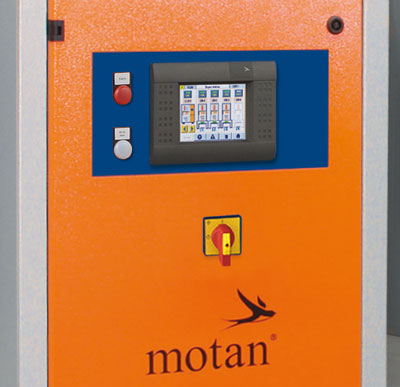

The monitor colour/color with screen TFT tactile allows the interactive navigation of the menus, what facilitates considerably the operation of the teams. The users can select all the essential parameters for the material of his election from a bank of data precargado. Likewise, the own formulas can store in a bank of independent data. Once that the user has selected in the granule of his election, the system ETA plus assumes the automatic control of the process. All the necessary parameters for the process of dried store in the database. The team adapts (in the appearances of quantity, conditions, summer, winter, day or night) and continues with the process of dried fulfilling/fulfilling all the requirements and doing an efficient use of the energy.

Spectrocolor G, sustainable extrusion

So much the industry of the processing of plastics like the one of manufacturers of machinery for plastics confront the double challenge to satisfy the most demanding requirements of quality in the production and attain, at the same time, keep the fixed costs in a systematically low level. The mix and dosage of different materials for his processing occupies the first place in the list of priorities: the precision of the formulations and his proof are fundamental to reach the quality of the products and, in definite, attain the profitability.

In addition to the know-how of Motan in the systems of mix and dosage with the units Graviblend and Graviplus, the system Spectrocolor G now ingresa to the market of the extrusion with his volumetric version Spectrocolor V. Motan, of this form, expands his offer of products, designed to cover all the areas of the mix and volumetric dosage and gravimétrica of materials.

The modular and compact design of Spectrocolor G for the dosage by loss of weight (LIW) of remolidos and granular materials that flow easily offers him to the user a unit with a good relation between price and performance. The areas of traditional application are the one of extrusion with an alone husillo with feeding by flood and the one of extrusion with double husillo with feeding by husillo empty. This means that it remains covered all the variety of production, included the tubes, the profiles, the flat films, the films coladas and the irons of plastic. According to sources of the company, "a series of exhaustive proofs, in conditions of continuous operation, confirm a high exert of dosage accompanied of a proof of dosage of until 0,5%. This allows to guarantee a repetibilidad precise and reliable, in addition to a high confiabilidad in the process".

The Spectrocolor G is apt for the addition of six components with a respective capacity of between 0,2 and 1200 kg/h by axis of dosage. All the metallic pieces that go in in contact with the granules of material are built in stainless steel; all the hoppers of pesaje are instrumented with finders of glass to allow the visual inspection of the level of filled. The calibración automatic and the storage of data of recipes for a series of formulas of mixes are standard functions. To end to monitor the quality of the product, the heavy quantities and mixed compare of constant way with the nominal values by means of the control of feedback.

The exchange of data, the control of data and the connection in network of the registers of data of the process LIW attain by means of an interface Ethernet that allows a handle complete of the materials. A small PC, with a tactile screen of 5,7" colour/color communicates with Soft-SPS. The technology Spectrocolor G can exchange information with databases and systems of management of the process BDE by means of a server OPC optional.

Hoppers Metro P feeders

When it treats to attain the safe and economic control of the process in the manipulation of dusts (like PVC and CaCO3) for systems of formulation and/or extrusion, the family of feeders of hoppers Metre/Meter P, that Motan presented in the market to ends of 2010, exerts, as they affirm, "a fundamental paper". The visitors of Powtech 2011, that will carry out of the 11 to 13 October 2011, in Nuremberg, Germany, will be able to see still more in the stand of Motan (7-431, in the pavilion 7).

The feeders of hoppers Metre/Meter P developed specifically for the continuous operation, clean and safe during the 24 hours of the day, the 7 days of the week and require little maintenance when they transport prime matters type N (that they do not flow easily) and type F (that they flow easily). To attain east exert, the systems are instrumented, like integral units of the range of products of Motan, with interfaces of control and mechanical of tested exert. To go back to fill the units of 15 and 50 litres/liters, the lengüeta of active download the bomb of empty by means of a signal.

The reason of the success and the confiabilidad of the process root in the fact that, as they affirm, "it results impossible that form obstructions or grumos". The geometries of the lengüetas of download calculate of empirical way, by computer and under conditions of laboratory; therefore, it guarantees a confiabilidad sustainable. The units of greater volume, that reach a capacity of production of 1000 kg/h, have an abertura of 260 mm of diameter for the flow of material.

The series Metre/Meter P is available in three measures: the compact unit, with a production of 200 kg/h and a capacity of 10 litres/liters (cycle); the average unit, with a production of 500 kg/h and a capacity of 25 litres/liters; and the unit of greater volume, with a production of 1000 kg/h and a capacity of 50 litres/liters. The classifications F, for dusts that flow with ease, and N, for prime matters that do not flow with ease, apply to the three units. The high containers, cylindrical and thin produce with stainless steel electro polishing and this does them resistant, extremely durable and easy to keep.

The quality of the filters is the initial point and the end in this technology of processing. The transport of sustratos and substances in dust demands the use of microfiltros in the air of transport. In the units Metre/Meter P, Motan uses several cartridges of filter. These filters of star characterise/characterize for having an extremely wide surface and a revestimiento of Teflon, by means of which capture , accumulate and filter the particles of dust finer and diminutas inside the rank of the micrones. With the model Metre/Meter P compact, that has a production of 200 kg/h and 10 litres/liters of volume, use four cartridges of filter. In the average unit (with a production of 500 kg/h and 25 litres/liters of volume) and the biggest unit (with a production of 1000 kg/h and 50 litres/liters of volume) use seven cartridges of filter.

Thanks to the decision of Motan to use a system of catchment of dusts with automatic nozzles of air, so much during the operation as in the process of transport, the cleaning, the safe maintenance and the care of the team in the range of products Metre/Meter P improved still more. Inside a clear-cut sequence and programmed, the current of return of the nozzle downloads of pneumatic way the cartridges indicated, that is to say, groups of four or seven that activate of selective or sequential way so alone a second before finalising/finalizing the cycle of transport.