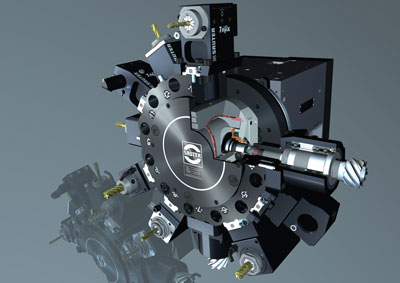

Revolver with integrated propulsion of tools

June 14, 2011

With the new Direct-Tool-Drive-Revolver, Sauter Feinmechanik has put the first stone for the complete machining in classical lathes. Engine integrated in the drive of tools get enormous performance data that allow greater profitability, better times of execution and, therefore, higher productivity of the lathe.

In the past, the physics put limits affecting the central proponent of tools of the revolver. Complex transmission with costly conical gear trains were subject to high wear due to collisions. This is seen especially in the milling operations with disrupted Court, as for example with polygonal fire.

Sauter Feinmechanik GmbH produced and patented a revolver of tools with integrated propulsion of tools: the 'Direct Tool tools revolver'. The tools of perforated, of milling and sawing of they trigger directly on the disk due to the integration of the propulsion engine tools. Why a costly transmission of the power of propulsion via propulsion trains is now unnecessary. Also reduce to minimize vibrations and the formation of heat, being clearly visible in the result of machining.

Direct propulsion of the tool allows a maximum number of revolutions in it amounting to 10,000 rpm. The best transmission of force makes you get a power of machining up to 4 times greater in comparison with conventional revolvers. Therefore, the old problems of lubrication of transmission in machining requiring a high number of revolutions belong to the past.

Therefore, with the new Direct-Tool-Drive-Revolver of Sauter can be both operations of turning as many forms of machining, for example, milling with court adjourned and milling of high performance with high volume of detachment of shavings.

Practical trials achieved magnificent performance of milling and excellent capabilities of boot of shavings. As well, with a special tool of milling it could reach a depth of cut of 5 mm, width of Strawberry 50 mm (5 mm) 0.25 mm of advance in mild steel with 1000 N/mm² tensile strength. Here is a rate in detachment of particle per unit of time for Q = 253 cm³/min. In this case the burden of the single engine amounts to 65%. Therefore still enough reserves to smooth out the cuts. Machining of high-performance with a revolver has only limits.

Another advantage is the combined use of the engine integrated in the drive of the tool for the propulsion of the same with rotating propulsion. Thus engine which was previously positioned outside is deleted and you get a compact and much shorter than the body construction. Thus, it is also possible to the integration of the revolver almost any surrounding even in situations of mounting where little space is available.

The control only requires an axis NC

Another advantage is that with the technology of single-engine an axis NC only needs to control the revolver. In the case of a manufacturer of machines, this affects on the one hand in costs and, on the other hand, the need of the wardrobe of distribution space.

To increase stability in the machining of high-performance, can be placed on standard tools drive the tool and driven in the usual accommodation DIN ISO 10889 - tools (VDI-tools) Additionally reinforced with a fixation for flange of 4 screws.

However, the expansion of the interface and the possibilities that this entails not limited the use of the usual tools DIN ISO 10889.

Performance values:

- Max speed: 10,000 rpm

- Max torque: 60 Nm

- Torque: 30 Nm (100% ED)

- Maximum power: 25 kW

- Rated power: 13 kW