Maspa installed injectors Kraus-Maffei in Ruby

The company transforms almost 1,000 tonnes per year of high impact polystyrene

The company Maspa, traditional manufacturer of material termoendurecido, got a year ago an order to produce the covers of the printers in inkjet that Hewlett Packard building in Sant Cugat, Barcelona. In less than three months, Maspa installed three injectors Kraus-Maffei and now transforms, at full capacity, around 1000 tonnes per year of high impact polystyrene.

Maspa, subsidiary of the German company Heinrich Baumgarten KG company, was installed for 24 years in Spain to manufacture accessories for batteries of kitchen and other pieces of material termoendurecido. For many years, this type of pieces represented the greater part of its production, as well as its parent company.

Production rate increased dramatically during the 1970s and 1980s, in parallel with Spanish battery of kitchen market and the rise of the manufacturers in our country of this type of product. The steady increase in its production made that Maspa return twice its factory, first in Granollers and later in Rubí, Barcelona industrial belt.

Maspa is an approximate market share of 25% of the material termoendurecido which becomes Spain. The Executive Head of the company, Hartmann H. k. Pahl, acknowledges that it is very difficult to increase current production, especially in the context of deep crisis in the production of kitchen in Spain batteries for many years.

The leap of Accountants

The Maspa solution to the problem of the decline of its traditional market went in the early 1990s to penetrate other markets. And he found one that now represents almost a third of its production: the manufacture of shells of electric meters.

Figure 1 The director of Maspa, H.K. Pahl, shows the cover of the printer that is manufactured with the fuel transfer Krauss-Maffei.

Figure 1 The director of Maspa, H.K. Pahl, shows the cover of the printer that is manufactured with the fuel transfer Krauss-Maffei.

The shells of the electric counters are a black square box of bakelita, with an open end and on the other hand with a window transparent thermoplastic enclosure that allows the reading of the counter of consumed electricity. Initially, counter tops were metal, with riveted glass window. Later were built of baketila and the window, plastic, adhered instead of riveting is.

Attached plastic window problem consists that it is very easy to take off her and manipulate the reading of the counter. Maspa solved this problem by injecting the window in the cover of bakelita, so the only way to separate the transparent window is completely breaking the lid.

Maspa system, to eliminate the possibility of fraud in the reading of the counter, has been very well received by manufacturers of counters and the company manufactures the covers for various manufacturers, including for the production of Siemens in Germany.

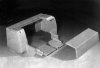

Figure 2 Cover of the printer Maspa manufactures with its plant in Rubí, Barcelona.

Figure 2 Cover of the printer Maspa manufactures with its plant in Rubí, Barcelona.

The manufacture of counter tops made unavoidable Maspa moved to a new ship. For three years, Maspa has a new ship of 1600 square meters in Ruby, about 30 km from Barcelona.

The opportunity of HP

The great opportunity of Maspa came, however, in April of last year, when Hewlett Packard proposed making the covers of your ink-jet printers. Hewlett Packard manufactures printers for all of Europe at its plant in Sant Cugat, which is less than 10 km from the Maspa.

Hewlett Packard requirements are very high, both in price and quality in delivery of the material. Responsible for Maspa, Hartmann Pahl, accepted the challenge involved in manufacture to HP, although he had less than half a year to design the entire facility and manufacturing at full pace, with the summer of medium.

Maspa put their trust in the German company Krauss-Maffei for the supply of the key machinery of the entire process: the fuel transfer. In the election, confesses Pahl, decisively influenced the prestige that have on the market the injectors of Krauss-Maffei and the appropriate support that for thirty years performs exclusively on Spain of these machines Coscollola commercial firm.

Maspa has in its production hall of some thirty of injectors, which serve for the production of thermoplastic parts and above termoendurecidas. For the strict requirements of Hewlett Packard, the company required injectors for increased clamping force and, above all, to ensure total quality of the finished product.

The mold is supplied by Hewlett Packard, which is why the fundamental choice were the injectors. The installation was designed based on an island in fully automated production, in which there are three injectors of thermoplastic KM 500-2300 B1 from the company Krauss-Maffei of 500 tonnes of clamping force.

The raw material is of high impact (HIPS) polystyrene and is centralized at one point. The raw material is transported by means tyres to the individual from each of the three machines dryers. There is also an individual group of cooling for every mold.

By demands of Hewlett Packard, seeking absolute uniformity of the colour of the case, the raw is already colored and of each consignment is sent a sample the central laboratory of Hewlett Packard to give its approval.

Pahl recognizes that the production system developed is simple but effective. The operatios only intervene at the end of the chain, when the conveyor delivers the finished prodcuto and is inspected before packing it. The surplus is automatically grinds and was reintroduced in the feed system.

Hartmann Pahl summed up in four reasons for choosing a fuel transfer Krauss-Maffei: it is a European manufacturer, has the necessary technical support through the Spanish firm Coscollola for which works exclusively, meets the specified requirements and the price is adjusted.

In recent years there has been an important concentration of manufacturers of injectors. For Pahl, it is important to choose as supplier for a company to ensure the future continuity of the service and, in his opinion, Krauss-Maffei gives. The fact that Krauss-Maffei is a manufacturer of small/medium-type also guarantees a personalised service.

In fact, in the thirty years that Coscollola is exclusive to Krauss-Maffei, the Spanish company has installed and gives technical support to nearly 1,000 machines in our country. Around this time, the number of problems with the machinery has been minimal, which shows, according to the representative, the high quality and soundness of the injectors.

Maspa investment in the installation has been of some 160 MPtas and the transformation of material capacity is about 1,000 T per year. Maspa, currently has a staff of 65 people and Bill close to 1,200 MPtas a year. In less than a year, production for HP has grown to represent almost one-third of the total of the company and they are already considering expanding the ship that just three years ago opened.

Lluís Alonso

| Maspa investment has been of some 160 MPtas and their total processing capacity is of about 1,000 T/year of other 1,000 tonnes per year of thermoplastic and thermosetting material | In less than a year, production of shells of printers has grown to represent almost one-third of the total of the company and Maspa already arises expand his ship |

| The great opportunity of Maspa came in April of last year, when a major client proposed making the covers of your ink-jet printers | In the election of the Krauss-Maffei injectors influenced its prestige and adequate support and technical service that for thirty years made commercial Coscollola |