This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Análisis Numérico de la Laminación Plana en Frío del Aluminio AA3004Other

Analysis numerical of the flat rolling aluminium cold AA3004

R. a. Ortiz, C. Vallellano and f. j. García-Lomas

Department of mechanical engineering and materials

School of engineering, University of Seville

Path of discoveries, s/n, 41092 Seville, Spain

Tfno.: 954 48 73 11; e-mail: carpofor@us.es

01/12/2002 1. Introduction

This paper presents a study of the process of forming flat cold of aluminium AA3004, focused on the particular case in which we work with values of and high friction. The parameter was defined by Li and Kobayashi [1] as the radius of the rollers and the initial thickness of the material.

These authors noted that, in order, the distribution of pressure in the contact zone presents two highs well defined as opposed to a single peak as usual. This paper analyzes the evolution of the tensions in the contact in such situations, as well as the distribution of residual stresses that appear in the product with different reductions in thickness.

2. Numerical simulation

For this study is a 2D finite element model in deformation flat of the lamination process. The commercial package ABAQUS is used. Analysis done rating considers, among other things, an elasto-plastic behavior with isotropic hardening aluminum, friction, heat generation by friction and plastic deformation and heat exchange between the rollers and the working material.

3. Results and discussion

Upon validation of the model with experimental results in the literature, have been tenso-deformacional and thermal States in stationary regime during the rolling process.

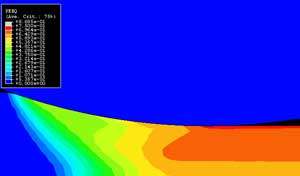

Figure 1. Def. Equivalent plastic. (40%)

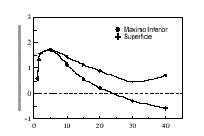

Figure 2. Residual stress vs. reduction.

Finally obtained and discussed distributions of voltage in the contact, the situation of the neutral point and the evolution of residual stresses (Figure 2) using different reductions.

4 Conclusions

The obtained conclusions are aimed to evaluate the applicability or otherwise of the classical analysis of rolling to the type of situations discussed in this paper.

5 References

[1] Li g., S. Kobayashi, Rigid-Plastic finite-element analysis of plane strain rolling, j. Eng. Ind. 104 (1982) p.55.