Plastics and moulds

Application of the carbon fiber reinforced thermoplastic laminate resistance welding

I González Requena, J.M. Sánchez García del Toro, f. Cruz García

Department of materials and aerospace production. Aeronautical ETSI. UPM.Cardinal Cisneros Plaza, 3 28040 Madrid. 91 3366330. IGR@Aero.UPM.es.

01/12/2002 1. Introduction

The objective of this paper is to characterize the process of welding carbon fiber inserts by electrical resistance of thermoplastic material (PPS and PEI) parts reinforced with fibers of carbon.

It aims to achieve the merging of the thermoplastic from the heat dissipated by Joule effect in a resistance (carbon fiber).

The fact of replacing the metal inserts (mostly stainless steel mesh) [1-5] that you have been using so far by carbon fibre inserts is intended to eliminate all the problems of the incompatibility of materialsput that in the parts manufactured by electric welding insert remains in the interior of the final piece.

2 Experimental

Control of process parameters are as follows: current that flows through the Insert (indirectly), thick inset, value of the applied pressure and time of application, amount of material contribution and duration of the trial [1]. For its part, the data from each trial will be the working temperature reached and the quality of the obtained Union.

Instruments used in the taking of temperatures were a pyrometer Raytek MX4 infrared, and a camera Thermographic FLIR SC2000.

3. Results and discussion

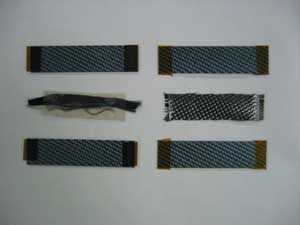

One of the main results refers to the placement of the fibers that are inset. It should be avoided as far as possible that there is intermingling or twisting of fibres, as decreases in length caused by high temperatures reaching carbon fiber because it has a negative coefficient of thermal expansioncause efforts of inflection in them that lead to breakage.

4 Conclusions

The results achieved so far can ensure that the carbon fiber inserts are suitable for use in welding of thermoplastic matrix composites highlighting the fact that do not introduce any foreign EU material as main virtue.

5 References

[1] I. González, D. Iñesta.; J.A.Urbano, Proc. AMPT'01 (4) (2001) p.1

[2] I. Fernandez, M. Frövel, l. Rubio, j. Diaz, i. González. Proc. 22nd International SAMPE Europe Conference, Paris (2001) p. 357.

[3] A. Offringa, D. Myers, a. Buitenhuis. Proc. 22nd International SAMPE Europe Conference, Paris (2001) p. 331