Simulation of the cutting of ductile materials with defined geometry tools

(1) Dept. of engineering mechanics - school Superior of engineering of Bilbao

c/Alameda de Urquijo s/n E-48013 Bilbao. e-mail: imaceega@bi.ehu.es tf: + 34-946017235

(2) Fundación Tekniker - Dept. of processes of manufacture Avd. Otaola, 20 E-20600 Eibar, Guipúzcoa.

01/12/20021. Introduction

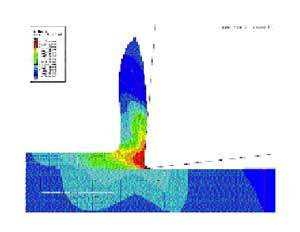

The work aims to achieve a better understanding of the formation process of the chips that will be useful for the correct definition of the cutting parameters. The modelling of the process will make it possible to tackle a route of analysis more convenient than the one based on the method of trial and error, as usual in machining processes.

For the simulation of the process of cutting a finite element method has been used explicit rating.

The validation of the model has been through testing of orthogonal cutting, mecanizing hollow cylinders of steel operations of refrentado, under the same conditions in which is the modelizado.

2 Experimental

3. Results and discussion

The factor of greatest influence at the Court is the angle of detachment of the blade, thus corroborating the simulation results from experiments.

4 Conclusions

5 References

[2] K. Komvopoulos and S.A. Erpenbeck, Finite Element Modeling of Orthogonal Metal Cutting, Journal of Engineering for Industry, 113 (1991), pp. 253-266