This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

La muela, derivada del perfil del estátorMachining

The grinding wheel, for the profile of the stator

A.R. Gonzaga

ETSIIT - Universidad Pública de NavarraArea of engineering of the manufacturing processes

C / Campus Arrosadía s/n. 31006 Pamplona (Navarra), Spain.

RA.Gonzaga@unavarra.es

01/12/2002 1. Introduction

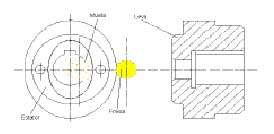

In the operations of grinding of profiles [1], a wrong selection of the grinding machine grinding wheel affects greatly as a whole and the profiles of the stator sheets. For this reason, the diameter of the grinding wheel depends primarily on the spokes of the profile of the stator. The consideration and analysis of this unit is required to avoid deformations on the surface of the profile during the grinding process, which may arise as a result of the uncertainty in the dimensions of the grinding wheel [2]. Also, the roughness on the surface of the profile of the stator leads us to search for a method suitable for the selection of this. A procedure that allows the optimal selection of the diameter will be displayed in this work.

2 tools employed

The program Matlab and Qbasic to simplify results and extraction graphs [3] has been used in this analysis.

3. Results and discussion

The results obtained are indication of accuracy of the analysis made in this work. In the table I different radii are obtained to select the grinding wheel. Take the child and is rounded up to the next integer. The mathematical expression for the obtaining of these radios, this given by the function of the characteristic of curvature RADIUS for the role of the analyzed profile.

4 Conclusions

1. The method used in this work, for determining the diameter of the grinding wheel to carry out the grinding of the profile, is the most appropriate method to reduce the roughness in the rectified surface of stator.

(2) If the diameter of the grinding wheel is inappropriate for the grinding of the profile of the stator, this will influence the geometric integrity of the profile and, as a result, will produce great vibrations in the fluid of the stator. For this reason, your selection should be conducted in such a way that guarantees a correct grinding.

Figure 1. Grinding of the profile of the stator.

5 References

[1] Storz, g. e., "Theoretical model of contour grinding". Master Thesis North Carolina State University, Raleigh, NC, 1994

[2] Gonzaga a. C., Mishlevski, l. M., "A Comparative Investigation of Profile for Stator of Driving Pump." Master thesis, Moscow, 1999

[3] Gonzaga a. C. Gates I, manufacturing of profiles for stator (part 1: analysis of the profiles for stator), sent to the Rev. IberoAm. deIng.Mec