Study of the drilling of carbon fibre

University of Cádiz. Dept. mechanical engineering and Industrial Design. ESI.

C / Chile s/n, 11003-Cádiz. Tel. 956015123 e-mail: mariano.marcos@uca.es

01/12/20021 Summary

In that regard, one of the alternatives more force has gained in recent decades has been related to the hybrid structures fibre of carbon/substrate metal, which have given rise to the so-called laminated materials or MLF. The usefulness of these materials, its range of applicability in the aerospace industry and its use in various structural elements of the aircraft are in continuous growth.

In this context, due to the requirements of Assembly of the aircraft, such materials should be subjected to a multitude of drilling processes. However, this kind of process is particularly problematic in the previously referred materials.

In most cases the main problem of the machining of these structures is supported by the drilling of the sheets of carbon fiber (FC).

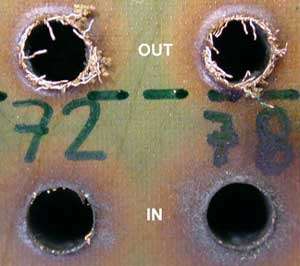

Thus, the main problem with the drilling of carbon or glass fiber sheet is the peeling in the input and output of the tool, Figure 1.

In addition, due to the high sand of this material, can have effects of wear and breakage tools, Figure 2. Similarly, if conditions of machining are used in dry and without inclusion of aspiration devices, can be locks the channels for the disposal of the cut material, as shown in Figure 2.

This work presents the results to study different cutting conditions the drilling of sheets of carbon fiber of various thicknesses, in conditions of maximum aggressiveness machining.

According to the results obtained, the tools with coating of CrN and the toilet are which have maximum performance, measured from the number of taladrados made prior to the replacement of the tool.

another in the drilling of FC