This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Estudio de los problemas de adhesión en el torneadoMachining

Study of problems of accession in turning

J.M. Sánchez, M. Álvarez, M.S. Carrilero, J.M. González, j. Cano, M. Marcos

University of Cádiz. Dept. mechanical engineering and Industrial Design. ESI.C / Chile s/n, 11003-Cádiz. Tel. 956015123 e-mail: mariano.marcos@uca.es

01/12/2002 1. Introduction

The mechanism of adherence is one of the main drivers of the wear of cutting tools, performing in a wide range of temperatures. By this mechanism, particles of the cutting tool may be attached to the chip or the machined piece. However, this accession process can also occur in the opposite direction, through the incorporation of fragments of material of the piece to the surface of the tool. Generally, these fragments are mechanically unstable and can boot tool particles causing wear. The material of the piece attached to the surface of detachment of the tool can occur in the form of recrecido Ridge (Built-Up Edge, B.U.E.) or extending to the face of detachment of the tool's wider areas, giving rise to the so-called layer attached (Layer Built-Up)(, B.U.L.), [2,3].

From considerations on the distribution of temperatures in the tool, [1] sets out the differences between the mechanisms of formation of both effects for AA2024 alloy machining.

This paper contrasts this hypothesis for the turning of the alloy AA7050.

2 Experimental

Is tornearon with tools of TiN alloy AA7050 cylindrical bars for periods of 10 to 0.1 seconds, using speed of court between 30 and 180 m/min and advances between 0.05 and 0.3 mm/rev., with a depth of 2 mm pass

Tested tools were studied by SEM and EDS, in order to analyze the microstructure and composition of the adherent material. A new tool was used for each test.

3 Results

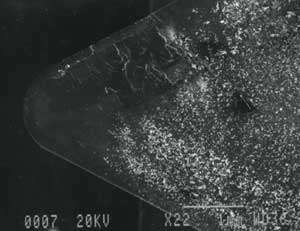

Figure 1 shows the image of the face of detachment of one of the tools employed. In the same accession of material can be seen in the area closest to the edge (BUE) and an extension of lower thickness away from the same (BUL).

Analysis by EDS in both areas has shown that the good is formed by the same material as the alloy composition of the BUL is next to the pure aluminum.

4 Conclusions

According to [1], these data confirm that the formation of the BUL is due to the softening of the matrix of aluminium which is welded to the tool and the drag of the intermetallic by chip, while the BUE is formed on the layer in the areas closest to the edge by effects of mechanical adherence.

Figure 1. SEM image of the face of detachment of one of the tools employed.

5 References

[1] M.S. Carrilero et al., Int. J. Mach. Tools & Manuf., 42 (2002) 215.

6 Acknowledgements

Work funded by CICYT (DPI2001-3747) and the Junta de Andalucía