Mechanised of aerospace components of titanium using the advanced strategy of mechanised for a greater volume of extraction equipment equipment of metal

The complex design of the pieces and the increasing demand has forced the development of new technologies and solutions of mechanised, so as to assist to the small and medium enterprise so that his production was more competitive.

The utilisation of titanium for the structure of the aircraft has not stopped to grow from the years 80, began to use in military programs, happening afterwards to the commercial sector. The alloys of titanium are a strong competition for the ferric alloys, of nickel and aluminium, so much in the military industry as in the aeronautical sector component manufacturing sector component manufacturing commercial.

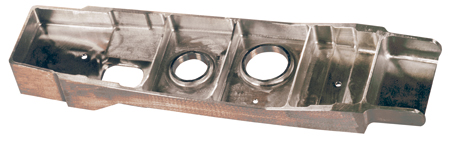

These applications cover entirely the range of all the structural pieces; from the structures of the wings, subjected to strong tensions, and components of the trains of landing, to small but critical components like hydraulics tubes, springs and abrazaderas. The new products of titanium, alloys and methods of manufacture employ increasingly in aeronautical sector component manufacturing sector component manufacturing, by what the utilisation of the titanium is in process of continuous expansion.

The ingredients that do that the titanium was special

The election of the titanium for aeronautical sector component manufacturing sector component manufacturing applications is due to the specific properties of this metal, as they are:

- Relation between weight and resistance

- reliability

- resistance to the corrosion

- excellent mechanical properties

- thermal sensors expansion

Characteristics of the mechanised of titanium and his limitations

The titanium 6To THE-4V is the most used material in aeronautical sector component manufacturing sector component manufacturing because of the existent relation between his light weight and his high resistance. The mechanised of alloys of titanium requires some strengths of greater that the necessary for steel. However, the alloys of titanium present some metallurgical characteristics that do that his mechanised was more difficult that the one of steels of equivalent hardness.

The titanium is known by his capacity of hardening. This condition forces to employ angles of positive cut in the mechanised, that does that the surface of contact of the shaving with the zone of cut of the tool was very small. The high pressesure together with the friction generated by the step of the shaving gives like result an increase of the temperature in a zone located of the tool. The heat generated during the mechanised of titanium does not dissipate quickly, because of the scarce conductivity. Therefore, a substantial quantity of heat remains trapped between the edge of cutting and the frontal surface of the tool.

This combination of high strengths of friction and temperature produces a mechanism of wear by craterización in the vicinity of the edge of cut, giving as resulted a fast break of the tool.

Given his relatively low modulate of elasticity, the titanium is more flexible that the steel, by what the area that is cutting tends to refuse the tool, unless the tie up of the piece was the ideal or that apply conditions of mechanised heavy. The pieces of thin walls tend to curvarse under the pressesure of the tool, ocasionando vibrations, erosion in the tool and problems of tolerance. The solution is to guarantee the rigidity of all the system and use tools with edges of alive cut and the correct geometrical characteristics.

To worsen the things, the alloys of titanium have a strong tendency to alearse or react chemically with the material of the tool to the temperature generated during the mechanised, and to ocasionar wear by transfer of material, since the shavings sueldan to the edge of cutting.

Milling trocoidal, solution advanced for a high extraction equipment equipment of metal

A strategy that is earning strength to obtain some high indexes of extraction equipment equipment of metal in the mechanised of titanium is the milling trocoidal. The mechanised of cavities in titanium, already are of little or a lot of depth, is a difficult task. To start with, a big portion of the tool is continuously in contact with the piece, by what the strengths of cutting and the heat generated are very high. A second point to take into account is the uneven load of shaving by tooth, more elevated in the point of the tool that more has advanced, and lower in the rest. The last point is the evacuation of shaving, since the tool occupies almost all the width of the slot. It remains very little space, by what the possibility to go back to enter shaving in the cut is very high and at all recommended, having to avoid in the possible.

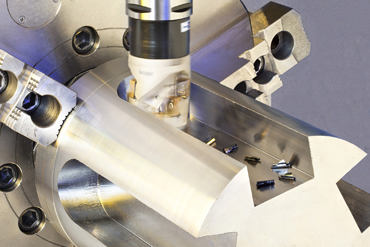

The centre of investigation and development of Iscar promotes and recommends the milling trocoidal and has improved the development of milling cutters with mango of integral hard metal and milling cutters multidiente for a high productivity using plaquitas interchangeable.

In this sense, the milling trocoidal can apply easily using a big variety of milling cutters Iscar. However, to obtain some excellent results recommends use the new development Chatterfree (Antivibratorias) of Iscar, and the lines Helido or Helimill (helicoidal geometries) with plaquitas interchangeable.

The challenge in the mechanised of titanium is still greater when the slots are relatively deep in relation with his width, since the evacuation of the shaving is more difficult. This point hampers even more in the case of slots curves.

Usually these difficulties do necessary that work with low advances and depths of cut, to avoid vibrations and a premature break of the tool. These conditions do that the productivity diminish. Even with low advances, the length of the tool is lower when they mechanise slots.

Milling trocoidal, a potential solution

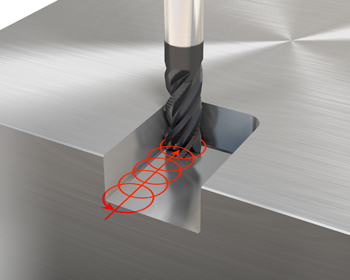

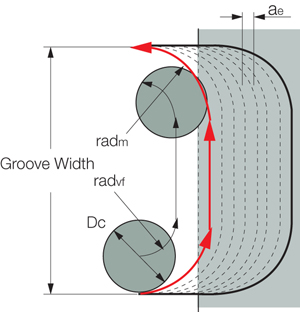

The milling trocoidal, or spiral, offers a potential solution to this problem. The basic idea is that the strawberry move following a pattern circulate in which each circle advance in the cut. A key advantage of the milling trocoidal is that only a small part of the strawberry is in contact with the piece. The advance is constant. Besides, the milling trocoidal makes possible to use a strawberry of lower diameter that the slot or cashier and facilitates the evacuation of shaving (see fig. 1 and 2)

The milling cutters Chatterfree of Iscar, with configuration in passing variable, no only deletes the harmonic vibration during the milling trocoidal, also has showed to have an extraordinary capacity to open complete slots and cavities, regarding the indexes of extraction equipment equipment of metal. Chatterfree Also offers the additional advantage to have a more prolonged length thanks to the reduction of vibrations. Chatterfree Can mechanise complete slots of until 2xD with 4 or 5 lips, even in machines of low power with adaptations ISO40 or BT40, without reducing the productivity.

The exceptional quality IC900 of Iscar with the advanced coating PVD TiAlN offers some incomparable mechanical properties that do that this strawberry of integral hard metal was the optimum selection for the milling trocoidal.

An alternative is the utilisation of plaquitas interchangeable, like the lines Helido or Helimill of Iscar, with milling cutters multidiente. Once that the strawberry multidiente has initiated the milling trocoidal, each edge of individual cutting goes in in the piece generating a heat and a minimum effort. The advantage to use milling cutters multidiente is the high advance by tooth that can apply , what translates in an a lot greater productivity.

In spite of his potential, the milling trocoidal also presents some challenges. The strawberry has to realizar a complicated movement that can go further of the capacity of the systems of programming CNC conventional. Besides, the machine has to be the sufficiently rigid and fast for the milling trocoidal. The strawberry has to be able work to high speeds and be adapted for the material. The rigidity of the machine determines the degree of possible aggressiveness of the milling trocoidal. Other factors that influence are the size of the strawberry, the material of the piece and the depth of cutting.

The basic idea of the mechanised trocoidal involves a substantial increase of the speeds of cutting and of the indexes of advance; the shavings cut to his maximum thickness at the beginning of the cut and goes diminishing to the end of the same (milling in concordance). The path of each tooth bases in the results of cycles of mechanised previous, deleting movements in the air and minimising the movements of retracción.

Profits of Costs

One of the profits is that they can mechanise slots of greater diameter that the one of cutting. This wants to say that they can mechanise different widths of slots with the same diameter of tool of an efficient form. Like the depth of cut is small, can use milling cutters with greater number of teeth, what involves greater advances and speeds of cutting that in conventional applications of milling of slots.

Milling trocoidal, challenges of programming

The software of programming CNC conventional usually can not generate programs for the milling trocoidal. The only form to realizar this type of milling for the programmer was to encode manually the complex movement that had to realizar the tool. However, the programmer could not check visualmente the program without executing it in machine. For this reason the milling trocoidal does not use a lot. Recently the designers of software CAM have added sections of routines for the milling trocoidal so as to reduce the necessary time of programming CNC. This option gives to the programmer access to other tools like the graphic simulator of mechanised.

The proofs realizar have showed that it is faster the milling trocoidal that the conventional system of milling of slots, since they can apply some a lot greater conditions.

An example of how the milling trocoidal can improve the productivity and reduce the cycle of mechanised, as well as the costs associated, is to see the strawberry Chatterfree of Iscar in action.

Real case of mechanised of an aeronautical sector component manufacturing sector component manufacturing piece of titanium by means of milling trocoidal

The milling trocoidal improvement substantially the productivity of operations of milling of slots. The usual practice of milling of slots is to apply an advance of roughly 20% of the that would use for a milling normal side. The milling trocoidal allows to increase the advance until 80% of the used for milling conventional. The intention is to show clearly how the milling trocoidal reduces the tensions and the heat generated during the mechanised. Although the speeds and the advances are a lot greater that for a milling of conventional slots, the wear of the tool is identical. The material used has been titanium You-6To the-4V (Quality 5), Recocido.

Milling Trocoidal

Mills Iscar: ECH160B32-6C16

Quality of hard metal IC900

Diameter of strawberry: 16 mm

Vc=115 m/min

Fz=0.12 mm/d

Ap= 22 mm

Ae=1-1.5 mm

Refrigerante: Emulsion

Time to produce a piece: 33 minutes

Length of the strawberry: 4 pzas.

Adaptation: BT40

Notes: Substantial reduction of the load of the machine. The machine realizar easy and soft operations, as if it worked with material of easy mechanisation.

Milling Conventional

Mills Iscar: EFS-B44 16-34W16-92

Quality of hard metal: IC900

Diameter of strawberry: 16 mm

Vc=45 m/min

Fz=0.04 mm/d

Ae=12 mm

Ap=12mm

Refrigerante: Emulsion

Length of the strawberry: 4 pzas.

Time to produce a piece: 55 min

Adaptation: BT40