New system of application for innovative coatings sun-gel for the aeronautical sector component manufacturing sector component manufacturing sector

Dr. Ana Valero Gómez, Unit of Chemical Technologies-

The development of new protective systems against the corrosion, sustainable with the environingingment and with properties highly adherentes that they ensure his durability, is one of the main aims in the aeronautical sector component manufacturing sector component manufacturing sector. This situation comes motivated mainly so much to environingingmental regulations [1-2], as to the high costs of maintenance associated [3], as well as the costs of labour hygiene and environingingmental management that comports said maintenance [4-5].

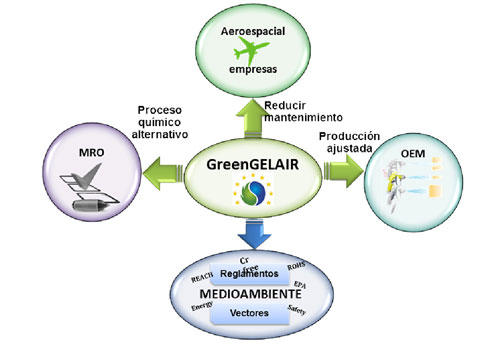

The results of the project GreenGELAIR will provide a new system of application of innovative coatings to the aeronautical sector component manufacturing sector component manufacturing sector. This system, based in developments sun-gel, will be respectful with the environingingment and will obtain high provision regarding adhesion and protection against the corrosion of the aluminium. Besides a new and versatile device of application, specific for this innovative coating, will be designed and built facilitating his utilisation so much for operations of maintenance, MRO, as in the manufacture of new equipment, OEM.

Systems of painting on aluminium in the aeronautical sector component manufacturing sector component manufacturing sector

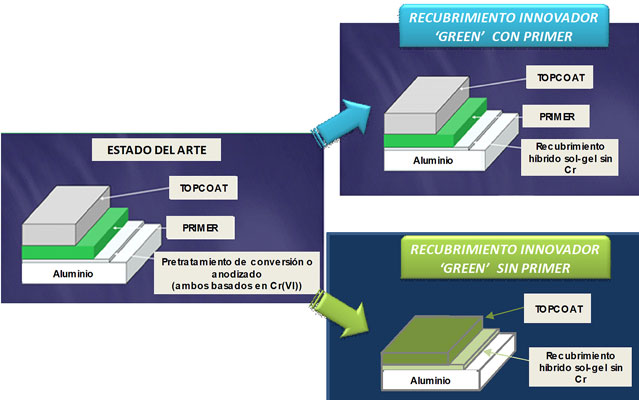

The current systems of protection against the corrosion in the aeronautical sector component manufacturing sector component manufacturing sector base in systems of painting multicapas. These systems, traditionally, base in a pretratamiento realizar on the consistent aluminium in a layer of chemical conversion that contains cromatos, to continuation adds him a first organic or primary layer (first) with inhibidores of the corrosion and promoters of adhesion whose function is the union between the metal and the system of painting. After this primary, the systems of painting can contain distinct successive layers. For the external parts of the aeroplane is usual to find systems with a secondary layer and a finishing or top-coat whereas for the inner parts of the aeroplane the intermediate layer does not be used to use. The last layer bases in polymers type polyurethane that provide properties barrier to the system as well as aesthetic. The final function of the system of painting is to warn and retardar the aggressive effects of the half on the metal.

At present the main aeronautical sector component manufacturing sector component manufacturing companies have developed alternative to said pretratamientos chromic. Between the diverse existent alternatives fit to stand out the process TSA (Tartaric Sulphuric acid Anodising) developed by AIRBUS, or the BSA (Boric Sulphuric Acid Anodising) developed by Boeing. Both are electrochemical processes that are not possible to use in the operations of maintenance and repair (MRO) or in retouchings on line of production. In these cases still is usual to use products in basic chromium, mainly AlodineTM, applied in stick for surfaces very small.

On the other hand, between the no electrochemical processes alternative, fits to stand out the system Boegel developed by Boeing and based in processes sun-gel or the process PreKote developed by Pantheon Chemical and implemented by Dassault Aviation based in bipolar organic systems.

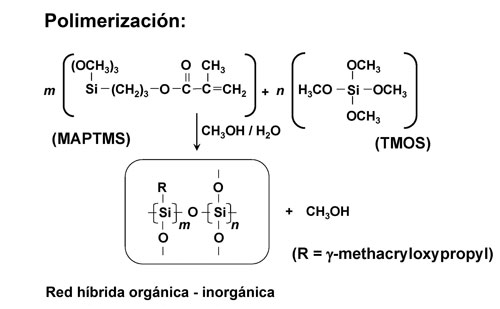

The alternative that is carrying out in the project GreenGELAIR bases in the development of a new and competitive hybrid coating sun-gel that improve the provision of the current processes. The hybrid systems sun-gel present the elasticity of the organic systems and the chemical resistance and mechanical properties of the inorganic. The skeletons formed by links If-Or have an power of link of 445 Kj/mole higher that the one of the links of the conventional polymers with links C-C with an power of 358 Kj/mole [6-8]. This comports to a greater chemical resistance, since it needs a greater power to break the link, increasing the durability of the coating as well as the resistance to the atmospheric degradation, to the heat and to the radiation UV that the organic systems as they are the polymers.

In the project testearán two systems of painting, with and without primary system. This last like alternative to the inner paintings in aeroplanes.

Project GreenGELAIR – Program Clean Sky 7PM

The main aims of the project are the development of the formulation of a new and competitive product sun-gel as well as the development of an innovative and versatile system for his application so much in operations of maintenance, (MRO) as in manufacture of original pieces, (OEM). The execution of the project will allow to obtain a more ecological alternative in the process of painted of aeroplanes. The main aims of the same show in the following figure.

Aimme, like leader of the project, has the support of the University Carlos III of Madrid, UC3M like technological partner and developing expert of products sun-gel that increase the adherencia in paintings on substrata metallic. Also it has the company Galvatec like expert partner in operations so much of MRO as of OEM in the aeronautical sector component manufacturing sector component manufacturing sector. The promoter of the project is the French company Dassault Aviation and has the financials of the 7º Program Marco and the conjoint initiative Clean Sky 2013.

Inner of the cabin of painted in Galvatec.

Structure and stages of the project

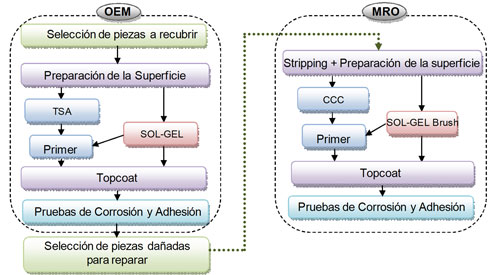

In the following figure shows the sequence of work in the activities of demonstration to validate the product sun-gel and his device of application developed in the project:

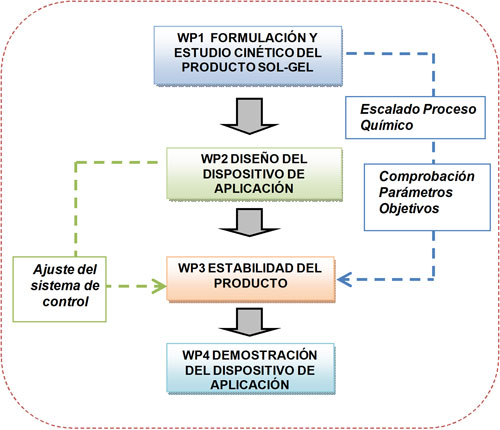

The project structures in four technical phases related between himself as it appears in the Figure 4.

Appears 4.

Degree of innovation

The system sun-gel proposed will be versatile and competitive, minimising the operations of maintenance and costs and deleting the environingingmental problems of the current systems. The results of the project are of direct application in the aeronautical sector component manufacturing sector component manufacturing sector although they also will be able to be applied in other sectors with processes of treatment of similar surfaces, as they can be the car or the one of industrial maintenance. This project has received financials of the seventh program mark (FP72007-2013) inside the program of the Conjoint Initiative CleanSky under granting of agreement n ° 620136. The promoter of the project is the French company Dassault Aviation.

Bibliography

[1] Registration, Evaluation, Authorisation and Restriction of Chemicals-Regulation REACH EC number1907/2006, http://ec.europa.eu/environingingment/chemicals/reach/reach_intro.htm

[2] OSHA, Occupational Safety and Health Administration. http://www.osha.gov/sltc/hexavalentchromium/index.html

[3] Report of the Ad hoc Committee on Life Extension and Mission Enhancement for Air Force Aircraft, Vol. 1, Executive Summary, US Air Force Scientific Advisory Board Report No. SAB-TR-94-01, Washington, D.C., 1994

[4] And.Joshua Du et al. Progress in Organic Coatings 41 (2001), 226-232.

[5]Managerial 2004/42/CE relative to the limitation of the broadcasts of volatile organic compounds (COV) owed to the use of dissolvent organic in determinate paintings and varnishes.

[6] J.M. Keijman, Properties and use of inorganic polysiloxane hybrid coatings for the protective coatings industry, in: 2ace Days gives Magazine Corrosao and Proteccao of Materiais, Lisbon, November, 2000.

[6] N.R. Mowrer, Performance Coatings and Finishes, Polysiloxanes, Ameron International, 2003, November.

[7] J.M. Keijman, High Solids Coatings: Experience in Europe and USES, in: Proceedings Protective Coatings Europe Conference, Paper 40, The Hague, The

Netherlands, March, 1997.