Interview to Hendrik Abrahams, scientist of the Institute of Technology of Mechanised (ISF) of the Technical University of Dortmund

They are arising a crowd of new materials. When and how it goes in at stake the cryogenic technology, that is to say, cool using technical gases?

The cryogenic cooling in himself is not at all new since in the years 50 carried out in EE UU the first essays of cooling with CO2. To finals of the decade of the 90, the University of Columbia realizar a big project of investigation with twelve industrial companies on cooling with nitrogen. In 2003 the ISF began with steels of high alloy, and in the last years has been working acutely in the cryogenic cooling for the mechanised of special materials like the alloys of titanium and of nickel. The cryogenic cooling is an intelligent election for the alloys of titanium, especially because when it treats of material used in the palettes, our options are very restricted. Here only they can employ hard metals for the tools, since the palettes manufactured in ceramics and CBN wear out immediately after a brief time of cutting. With the end to increase the levels of production during the mechanised of titanium with tools of hard metal, is fundamental to have of a concept of cooling that adjust to perfection. Here, for example, we have checked that the lubrication with cooling to high pressesure is effective.

Hendrik Abrahams, engineer graduated and scientist in the Institute of Technology of Mechanised (Technical University of Dortmund): “With the cooling by CO2 all reduces to a simple reality: it needs a deposit for the machine and a resistant pipe to pressesures”. Photo: ISF

What other reasons have carried them to adopt new concepts of cooling?

Allow to increase the useful life of the tools or the speed of cut, increasing the productivity of the process in question. This is certainly a factor highly motivator in the industry of aircraft that so fast is growing, since for example, the increase of the proportion of the fibre of carbon involves an increase in the use of the titanium.

Which concepts of cooling have examined, and which have been the results?

In ISF have realizar essays with cooling with stream of snow of flood, to high pressesure and CO2, in addition to combinations of cryogenic technology and lubrication of minimum quantity. In the case of Inconel 718, an alloy of nickel for a rank of high temperatures, checked that with a cooling CO2 pure and simple, the fault of lubrication causes a severe wear. When combining with the lubrication of minimum quantity (mechanised almost dry) reduced the wear in the open zones, as well as the wear in the slots. Nevertheless, the success depends of the type of feeding used, of the pressesure of the feeding of minimum quantity and to having chosen the correct oil for the lubrication of resistant minimum quantity to the cold. It keeps on being necessary to work in the design.

With the cryogenic cooling, you concentrate only in the CO2, what occurs then with the nitrogen?

Depends of the type of system of cooling of tool that use . For the cooling of internal tool, that requires a quite elaborated engineering because it is necessary to have of perforaciones for the refrigerante, can employ alone nitrogen. The reason is that the nitrogen remains to a temperature of almost –200 °C during all the process of feeding. For the external feeding of the refrigerante through the filters, so much the nitrogen like the CO2 are suitable. When it uses CO2, his temperature is of less 82 °C, and even not being a so low temperature like the one of the nitrogen, the specific heat capacity is greater, since the CO2 keeps in liquid state until it goes out by the filter.

What does him think that the cryogenic cooling is a genuine tendency and no only an advertising bass drum, like other technical developments realizar previously?

In the first place, the aeronautical sector component manufacturing sector component manufacturing industry has a significant demand regarding processes more efficient, and second, from the point of view of a researcher, have identified the main advantages of the cryogenic technology like option of improvement for the levels of productivity. The interest centres in this appearance, as it has showed it Premium Aerotec GmbH, one of the providers of components leader of the sector, that already has purchased machines with cryogenic cooling and is testing the technology in question.

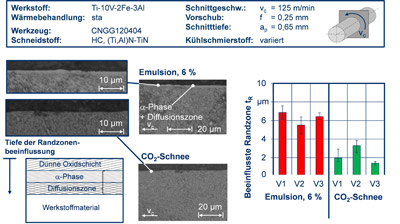

The snow guarantees an effective cooling. The ISF of Dortmund has showed experimentally that, in comparison with the conventional cooling and of high pressesure, the wear reduces significantly when working with snow of CO2. Chart: ISF

And regarding the costs that this involves?

The profitability of the cryogenic cooling depends of the consumption of CO2. To reduce the costs of the consumption of carbon dioxide, have carried out different studies. In this sense, have checked that if it diminishes significantly the mass flow of CO2 —more exactly of 2,7 to 0,6 kilograms by minute—, the mechanised can give place to results equally good. When it attains optimise and reduce the consumption of CO2, together with a considerable increase of the productivity, can assume that the cryogenic cooling gives good results.

They will be necessary new tools for the cooling with stream of cryogenic snow?

New tools no, but it will be necessary to modify the existent. They can use the tools designed for the cooling of high pressesure, and adapt his filters to the stream of snow of CO2 in terms of holgura, form, diameter and, as it correspond, also of position.

In other words it treats of something that the manufacturers of tools carry long looking for: the intensive cooperation between manufacturers of tools and manufacturers of machines-tool

Now, in the initial phase, the optimum stage would be to create a big project in collaboration with the manufacturers of machinery, several manufacturers of tools, a manufacturer of filters and an entity researcher like the ISF. Here they would have fit also projects sponsored by the government.

The ISF has showed the fundamental suitability of the cooling with stream of snow of CO2, go tackle now the details of design of the important parameters of the process?

Already have established some key statistics, like the possible increase of the useful life: the task now is to design and improve the concept for the production in series. In this sense, all the disciplines involved have to work in narrow collaboration.

It goes to be necessary to modify the machines-tool?

Is necessary that the feeding of the stream of snow of CO2 through the revolver —and in case of the milling, through the husillo— was tight to the gas and resistant to pressesures. The engineer commissioned of the design, however, does not have to concern by the thermal sensors compensation when designing the machinery, since in comparison with the cooling by nitrogen, has some extremely low temperatures some —200 °C. With the cooling by CO2 all reduces to a simple reality: it needs a deposit for the machine and a resistant pipe to pressesures. Therefore, it is relatively easy to add with hindsight this type of cryogenic cooling, turning into an obvious option for the manufacturers of machinery that want to obtain initial experience. In the case of the nitrogen, all the execution is more complicated.

Which is for you the strong point of his work?

Have tested experimentally that in the case of the alloys of titanium, the wear can reduce substantially in comparison with the cooling of high pressesure. Besides, thanks to the effective cooling of the point of action and to the trip of the oxygen, reduces the influence in the peripheral zones.