New trends of mooring in the aeronautical sector

Lasa Javier, Manager of SMW-Autoblock Ibérica

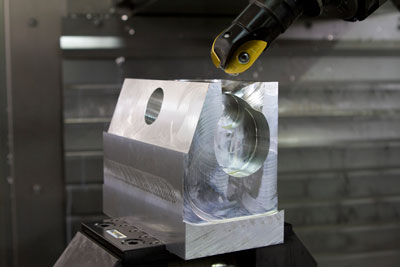

22/07/2013The engineering sector that works in the development of aerospace products and parts must comply with the requirements of reliability, quality and highly exacting tolerances. For example, machining of the workpiece completely on a single phase (mostly 5-axis machines) and save on raw materials, especially when it has a great influence on the price of the part (aluminium, titanium, etc, common in this market). Therefore, having a low clamping system but highly insurance that also prevents deformation of the clamped workpiece provides important advantages.

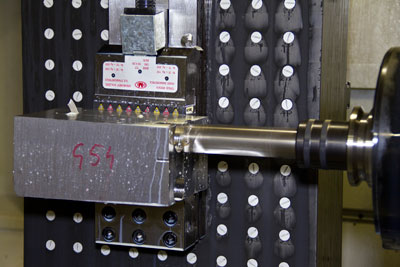

In order to respond to the high demands of the production of parts for the aeronautical sector, and thinking to better the performance of the machine and the tool - faster cutting + biggest advance = major chip cutting volume = less time to machine the workpiece - born SinterGrip. A system that allows you to tie the piece to 3.5 mm in height or even 2 mm using only a row of points. Riding the inserts Sintergrip they can tie directly, using any gag, pieces of up to a hardness of 50-54 HRC without making any prior or premecanizado marking of the piece, which is necessary with other mooring systems and generates additional costs.

At the same time, SinterGrip allows exceptional stability of mooring with total absence of vibrations.

The solution is to hard metal inserts sintered type ISO P30:P35 coated by PVD method.

Using inserts 5 by claw to tie steel with resistance 980 N/mm2 inserts penetrate 0.16 mm with 4,000 kg of clamping force.

It is worth to note that the coated hard metal currently represents 80-90% of all the inserts for cutting tools. The success of this material is due to its extraordinary combination of wear resistance and tenacity to do so add the triangular shape of the Insert, which creates a mesh virtually no game, ensuring an Assembly of precision insert the claw and turning it into a single body with the vise.

In addition, it also emphasizes special taper (5 degrees) of the section of the Insert, which creates an effect of axial thrust which is transmitted to the workpiece to be machined. This combined with the sharpening of probes is performed so that the bottom corner is more superior creates a double effect of axial thrust preventing the elevation of the piece.

In a general sense, insert with its special form of pyramid and sharpening tips help to penetrate the material to be machined and it creates a link with absolute absence of game, eliminating forces and vibrations and turning it into a unique body with the gag, the tooling of mooring and part to be machined.

SinterGrip sintered hard metal inserts exist in three versions, having the same technical characteristics, but differentiated by the type of tips sharpening and coating:

- With 12 points in the form of pyramid and TiN-coated steel insert

- Insert titanium and steel 50/54 HRC with 10 tips in the form of piramiede and TiAlCn-coated;

- Aluminum insert with 6 points with 4 lines of bumper and coated CRN/NbN pyramid-shaped.

Therefore, from the technical point of view, it proposes to the market in a way no particular restrictions for use. Simply tie the piece with a minimum force of 2,000 kg for aluminum or 3,000-4,000 kg for steel. Subject to this force, hard metal inserts penetrate automatically in the piece to tie creating a footprint of penetration points. It should be noted that each insert for steel has 12 points and, normally, 10 inserts are used in a gag (inserts 5 by claw). This allows to clamp the workpiece with 120 points that penetrate the workpiece. As a result, gag or the clamping tooling becomes a unique body with the piece to be machined.

Mooring of the piece in 3.5 mm. Using only a row of tips you may tie by 2 mm.

Another important advantage is that these inserts can be used in any clamp or tooling of berth already existing on the market, simply by mounting a pair of claws or directly using the inserts in the case of special tooling or self-centring plates. There are various solutions such as, for example, claws for gag ' All in One', a functional and innovative solution because these claws are already machined with the accommodation of the inserts, predisposed to various types of clamps with mounting holes to measure and also presented an additional plus: the coating tungsten carbide to a greater friction during the second phase of the workpiece machining. In fact, the tungsten carbide coating creates an effect of mooring exceptional, avoiding penetration into the piece that is naturally not allowed in second operation. The versatility of the mooring is maximum since at first operation it tied with inserts and in a second operation, without dismantling the claws, is moored at the bottom of high friction.