Dominate the situation in the workshop with a 'Tool Management' intelligent

Swen Hamann, director of Zoller

22/07/2013Exist in the market for highly efficient solutions for large, small and medium-sized businesses to manage easily from the high of a tool in the system until the preparation for machining machine. Simple processes which can be better organized with a smart Tool Managment. So costs for tools and accessories that are not controlled and do not increase downtime's machining by long periods of implementation to point are not generated.

A secure process for tools

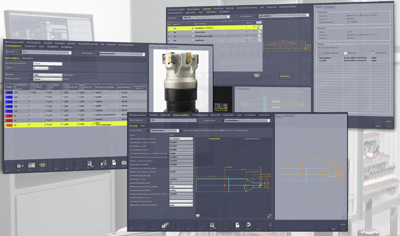

Intelligent software modules such as management tools, the management of warehouses, data transfer and management of NC programs, guarantee, combined with a Zollermeasuring machine, a safe tool process.

With a system existing CAM generates is the NC program, always using the same surface CAM tools stored in the management of TMS tools. This management tool saves standardized workshop tools and helps the CAM programmer in the selection of the tool. If necessary you can check shocks and then generate process sheet. In the next step are mounted according to the orders of manufacturing tools and will be measured on an automatic measuring machine, simple and independent of the operator.

Simply better organized

The generated process sheet contains all the information necessary for the manufacture of a part X. Here you will find the tools and their components, data data of the machine and the NC program and data regarding the piece as planes, tools, measuring, etc. This sheet process is not already passed as before in the form of cards or folders, but quick and secure way through the company's network. So they are available in the place where there is really the need for this information. Money management tools and stores be deducted tools or components necessary for part X. If the operator wants a list of required elements, which makes it easy for the tools can be printed.

Enormous savings potential

Storage tools such as individual components carries a very large savings potential, since expensive tools and components do not have to be duplicated because they are fitted to a particular Assembly. In every moment you can tell where are tools that have emerged from the store, according to cost, order or machine center. You can also generate a full inventory at any time and see the references used in the workshop.

Independent operator and secure manufacturing process

The measurement and verification of the tool is done fully automatic or manually according to the selected machine. Data output - format machining machine controlled - is carried out by pressing a key and then sent to the company's network. Errors of bad entering values in numerical control disappear.

Support for the organization with little cost is the use of barcodes in the leaves of process or the list of needed items. This allows you a quick and easy way riding starting from individual components or find tools mounted a tool.

Also for small and medium-sized enterprises

This process already works with a Zoller smile 400/pilot 3.0. Does not lack that is the version most comprehensive and automated; It depends above all until the level of control you want to arrive at the workshop. As it is a modular solution you can enter system step by step and thus ensure a good acceptance of the workers. The Zoller Management Tool is available in three packages, bronze, silver and gold offering transparency in the Organization of production. The user always has the correct process data at any time and thus dominates the situation at the workshop.