The challenge of the mechanised of the álabes

Technical department of

The majority of the costs of production of the turbines of gas and steam are the álabes. His geometrically complex structures are the only parts of the turbines with some character of production in series. The increase of the use of materials termo-resistant does the mechanised even more complicated and therefore more expensive. Therefore, they require innovative solutions of tools.

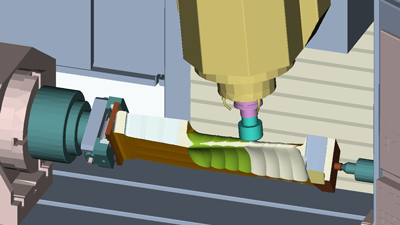

Simulation of the operation of desbaste of a álabe of turbine. Photo: IfP, University of Sciences Applied of Zwickau.

The mechanised of álabes is an own science in himself same. The mecanizadores were used to to have problems with the software or with the machine when they were milling the curvature wished, but the main headache nowadays in the material of the álabe. A wide rank of materials can be required to instrument a turbine with álabes, and therefore they are needed different tools and strategies. High temperatures are presents in the zone of high pressesures, what means that the materials termo-resistant are particularly sued. Foundries or alloys of titanium are also used in the zone of low pressesure. Here, it is not the temperature, but if the centrifuges strength the one who determines the material; other differences produce because of the type of álabes: The rotation of the álabes of the rotor generates a different stress to the that have the álabes fixed of guided, that is the reason whereby change the materials.

As it has commented previously, the big focus are the álabes of the zone of high pressesure. With the end to increase the efficiency of his turbines, the designers are allowing that the temperatures are higher in the entrance. For the mecanizadores, this development means greater costs of manufacture of álabes and pieces related. The extreme temperatures require special materials, álabes of stainless ferríticos, martensíticos or austenínicos are usually insufficient, is necessary to manufacture them in alloys termo-resistant with base in nickel. The increase of the utilisation of these materials of difficult start of shaving, also comports an increase of his time of mechanisation. The best way to keep the low costs is to use tools optimised with a maximum performance.

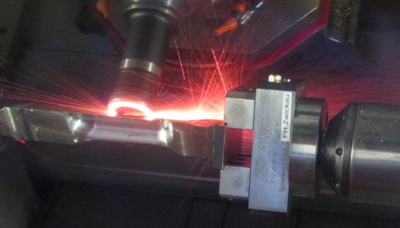

Desbaste Of álabe of turbine with plates of ceramics. Photo: IfP, University of Sciences Applied of Zwickau.

Walter is working in this, with the development of tools for the production of power that has a long tradition in Tübingen. “The production of power has been one of the main industries in which we have focused us during decades”, in words of Andreas Elenz, responsible of Development of Business in this area of Walter, provider of complete service for all the key components, that therefore it includes the álabes. “This means that we supply all the tools (and in the mechanised of álabes this means a good number), from the dishes of milling of desbaste for the maximum volume of shaving to milling cutters of integral hard metal for the traditional finishing of the lower radios”.

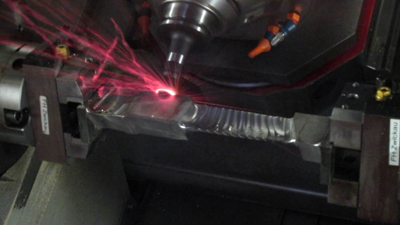

Desbaste Of the zone of union of the álabe with ceramic plates. Photo: IfP, University of Sciences Applied of Zwickau.

Tools optimised

Whereas some álabes of low pressesure are forged or melted, the majority of the álabes (particularly the ones of average and high pressesure) create milling from a solid block in special machines with axles highly dynamic. Between the 60 and 85% of the álabes are mechanised of this form. Thomas Schaarschmidt, leader of the team of Development of Energetic and responsible Businesses of the technology of mechanised of the álabes, explains that “the dishes of milling preferred for the desbaste are initially dishes of copied with round plates like our dish F2334R, that has been optimised for the mechanised of álabes”. The R is synonymous of design reinforced. A main characteristic of this dish is his high level of stability and therefore the reliability of process, and the fact that it is compatible with the mechanised in 5 axles. ”These tools”, continuous Schaarschmidt, “do charge of the 70-80 of all the process of mechanised, therefore it is in this application where produces the greater start of shaving”. Simultaneously the milling with five axles is now the norm, this means that the best geometry in relation with the strengths of cut can be established in any steering; also it is possible to approach to the outline of finishing with the tools of desbaste. The F2334R can be instrumented with the last materials of cutting. Walter has developed the degree PVD W3536 with oxide of aluminium especially developed for the mechanised of álabes. The ratio hardness/tenacity is between the standard degrees already known, WSM35 and WSP45. Other tools are of interchangeable plates like the milling cutters of escuadrar or milling cutters enterizas of finishing of hard metal, for example the external slots.

When the álabe has been desbastado totally, the semi-finished of the álabes is usually the following step. A typical tool of semi-finished is the dish of escuadrar F4042R or the new tangential dish of escuadrado Blaxx F5041, both types of dishes have the capacity to leave an ideal surface for the fine finishing. Milling cutters of ball with interchangeable plates like the F2139 or milling cutters of integral hard metal of ball or conical then do charge of the mechanised of the radii of transition. These last are at present still considered special tools.

Walter supplies the dish F2334 of round plate in a version with design reinforced like the F2334R. The tool has been optimised for the mechanised of álabes of turbine and is available with different systems of adaptation.Photo: Walter AG.

The extreme trees of the álabes (zones of back union) generally is a task of milling cutters with interchangeable plates with several edges of cutting. Since they require good surfaces of finishing in this stage of mechanised, the mecanizadores change the edges of cut of the interchangeable plates hardly appear a small wear in them. The ideal tools for these applications are the plates octogonales for example.

The finishing of the álabes of turbine is an extremely important process. The type of finishing and the curvature of the álabe determine the type of flow and therefore the efficiency of the turbine. “Two concepts of tool for this are available in Walter”, explains Thomas Schaarschmidt. ”Milling with conventional milling cutters integrals of hard metal or with our new system modulate ConeFit™ of interchangeable heads of hard metal. We use standard or special tools depending on the application”. The special tools have a big number of teeth, for example 10 teeth in a diameter of 16 mm. This means that an extreme linear advance and a good economic efficiency are achieved.

The dish octagonal of Walter that has been especially developed for the finishing of the rhombic zones of union of the álabes of turbine because of his big number of edges of cutting. Photo: Walter AG.

The ceramics has the advantage

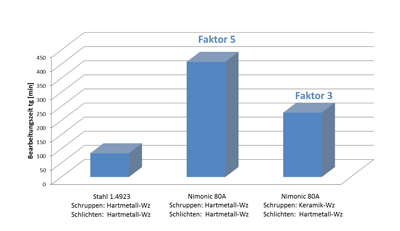

Walter collaborates closely with the Institute of Engineering of Production (IfP) in the University of Sciences Applied in Zwickau (Sajonia Western) in the development of tools and suitable strategies for the mechanised of this type of materials. The mechanised of the álabes of turbines is one of the competitions of this Institute. In the 2002/2003, the IfP llevar the first systematic study of the alloy with base in nickel Waspaloy. The result: The mechanised with tools of available hard metal in that moment was 12 slower times and expensive that the mechanised of turbines of steels. The development of the hard metal has been big. The last investigation that has llevar the IfP with the alloy in base of nickel Nimonic 80To and with the last available hard metals have confirmed that the original factor of 12 of additional costs has been reduced to 5. Even it can be possible reduce this factor in the near future. At present the specialists of Zwickau are llevar investigations on the mechanised cryogenic. The dishes to mill refrigerate with carbon dioxide in this type of mechanised. These developments, in which IfP and Walter are working elbow with elbow, are not still finished.

The specialists in álabes desvelan another thing more: only the ceramics like material of cut has reached the maximum performance in the mechanised of alloys termo-resistant more frequent. IfP Declares that thrice more than time needs for the mechanised of the conventional turbines of steel. The ceramic is a component in a global concept. Dishes with interchangeable plates of ceramics do charge of the desbaste, of the semi-finishing and of the finishing do load interchangeable tools or tools enterizas of hard metal. With the current state of the technology, the ceramic is only adapted for the operations of desbaste. Tools for other applications already are developing. These developments include tools enterizas of ceramics. “It will be possible a significante reduction of the time of mechanised when these tools of ceramics for the semi-finishing and the finishing are smart”, predicts Lucas Günther, assistant of investigation in the IfP. However, this development is totally dependent of the manufacturers of turbines. The extension of the ceramics to these applications depends on the quantity of heat that enter in the material. If they produce excessive temperatures, they will change the structural composition of a no allowed form. The requirements of the manufacturer and the possibilities from the punto of the mechanised are initially two no clear-cut variables.

Walter supplies special dishes for round plates of ceramics. Photo: Walter AG.

Going back to what is at present feasible. The high performance of cut of the ceramics bases in the special characteristics of the material of cutting. This includes hardness extremely high until 3.000 HV10 (hard metal: until a maximum of 2.500 HV10), high Resistance to the temperature of 1.100 °C (hard metal: maximum 1.000 °C), a low coefficient of friction and a low adherencia to the wear. However, these beneficial properties only can use if they fulfil several conditions. Everything depends on the good stability of the piece and of the low voladizo of the tool. The machine has to be designed to work to some revolutions between 15.000 to 30.000 rpm with the end to be able to use the pertinent strategies with high speeds of cutting. Also it has to be instrumented with a system of extraction equipment equipment with guides encapsuladas for the particles of ceramics that produce during the mechanised.

The system modulate of milling cutters enterizas of hard metal ConeFit of Walter provides a high degree of flexibility and therefore it is frequently used in the mechanised of álabes. Photo: Walter AG.

Andreas Elenz, director of the department of Development of Business of Walter in Tübingen, is engaged to a tradition: "The production of power has been one of the main industries in which we have focused us during decades”. Photo: Walter AG.

In the meantime, IfP has tested both degrees to optimise the dishes to mill and to develop the best strategies of mechanised. In accordance with Walter, the parameters of cutting more adapted for the degree Sialon WIS10 are of vc = 1.000 m/min and of fz = 0,1 to 0,4 mm/rpm and a past of top = 1 to 2 mm. “It is extremely important to determine that parameters of cutting and that strategies of mechanised are adapted for each material”, explains Thomas Schaarschmidt, ”therefore, our customers always receive a complete package that consists in tools and in technical knowledges”. In addition to the strategies, the design of the dish to mill is another form of adjust of the performance, continues the expert. Walter says that it has brought all his experience in milling here. For example, an important detail is the tie up of the interchangeable plates. Schaarschmidt Estimates that 30% of the performance of a dish with plates of ceramics is in the optimisation of the body of the strawberry.

Thomas Schaarschmidt, leader of the team of Development of Energetic and responsible Businesses of the technology of the mechanised of álabes in Walter: “The customers receive a complete package of tools and know-how”. Photo: Walter AG.

The interdisciplinary investigation of mechanised

The Institute of Technology of the Production (IfP) in the University of sciences applied of Zwickau, Sajonia Western, The department of Mechanical Engineering and Automotive sector, directs a laboratory of technology of last generation for “development of mechanised interdisciplinado for the solution of complex problems in the technology of production” under the leadership of the Doctor and professor Michael Schneeweiß. The basic competitions of the Institute include the mechanised of álabes of turbine, associate proofs for the development of tools and materials of cut, calculations of mechanised ultrasonic, of strengths and of performances for the processes of mechanised. The scope of the services also includes the optimisation of the mechanised on the base of the general analysis of the processes, the development of new technologies of mechanised and the mechanised of materials of difficult start of shaving, including new ceramic and abrasive materials. Several machining centres CNC and a wide range of materials to mechanise and of equipment of quality are available. The majority of the projects of investigation face up to tasks of the aerospace industry, to the industries of tools of cutting and to the manufacturers of machinery.

Diagram of time of mechanised. During the manufacture of álabes of turbine done of alloy to base of nickel Nimonic 80ª, the time of mechanised increases significantly in comparison with the conventional steels of turbine: it increases to a factor 5 if they use the modern plates indexables. The additional cost is lower, ej: a factor 3 if they use desbaste of milling cutters with plaquitas of ceramics. Photo: IfP, University of Sciences Applied of Zwickau.