Interview to Doroteo González, manager of Acatec

To start with, it could explain which are the works of Acatec for the aeronautical sector component manufacturing sector component manufacturing sector?

Acatec Is a company with more than 20 years of experience in the aerospace industry. From our origins like manufacturers of elementary metallic and originally sheet metal pieces coined and conformed have gone incorporating progressively new productive processes as mechanised, superficial treatments, essays no destructive, instrumented of groups and settings of structural elements.

At present our ‘core business' or main activities are the complete manufacture of elements mechanised and the setting of structural groups of aircraft, including in the activity the complete gestión of all the necessary processes, realised internally or with the collaboration of companies especially certified in the same.

Until the moment, for which companies work or have worked?

Between our main customers stand out Airbus, EADs, Aerometallics (group Aernnova) group Aciturri, CEASES, group Alestis, Burulan, Composystem, between others. The experience in the aeronautical sector component manufacturing sector component manufacturing sector is very wide, standing out the activities in the following programs:

- Airbus in all his families and especially: To320; To330 To350 and To380.

- EADS in the programs C-235, CN-295, Eurofighter.

- Embraer In the programs 145, 170 and 190.

In his opinion, which requirements has to fulfil a company mecanizadora so that a ‘big ‘' of the aeronautical sector component manufacturing sector component manufacturing bet by her?

If we want to resumirlo in only three words would say: offer complete solutions, qualities that offer distributors like Makino.

Originally the big companies requested individual and isolated solutions focalizadas to the necessary operations for the realisation of his products, that is to say requested the realisation of the works of each one of his productive sections, reserving the gestión and the control of the whole of the process.

At present request solutions more complex including no only the control of quality of the processes individualizados (or gestión), but the realisation of the group of the processes that allow the realisation of the complete elements.

To offer this level of exigencia is necessary to possess the technological capacity to realise it, but besides with the most advanced technologies and that allow us move us in some costs adjusted. Also it is necessary to have an able human team, no only with technical knowledges but with the capacity of interactuar in the processes and organisation. We do not forget that it is the following step requested by our customers. The once adjusted processes and optimised guarantee us the stability of production and the fulfillment of the characteristics demanded, but is the human team the one who, with his influence in them and in his sequence, obtains the best result of the group.

Besides, is vital to do a bet decided by the quality, hygiene and continuous improvement. These three concepts are indispensable in the industry in general but especially in the aerospace sector. And, on the other hand, we have to understand the terms of delivery like a characteristic more than the service requested. Any provider puts in doubt the characteristics of the products or services requested by a customer and reflected in the planes and specifications, but sometimes forget us of the date of delivery like requirement.

But our customer needs also our flexibility to adapt to the rhythm demanded. To date we have been accustomed to the challenges of reduction of costs and elements increasingly complex, but at present demands us increasingly changes and terms increasingly reduced, the dates of delivery adjusted are becoming more important. This exigencia that at first sight looks to be a big problem could be ours alternative to the deslocalización of our products.

With which machinery explain to fulfil with the requirements demanded?

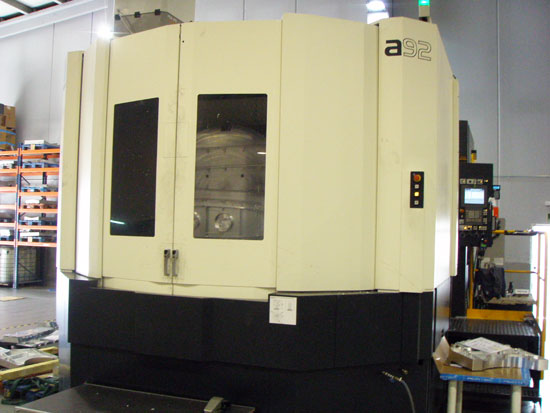

Ours installations are adapted with the most advanced equipment that have considered in each moment. If we centre us in the mechanised, in our installations have 21 machines of four manufacturers of first level.

Always have considered that have of a number reduced of manufacturers of our equipment is a value added when simplifying so much the needs of learning of our operarios, achieve a polivalencia of programs and operarios, as well as the reduction of the gestión of the maintenance.

The distinct capacities and specialisations can classify them of the following way:

- Machining centres by numerical control of high speed, vertical and horizontal paletizados of: 3 axles until 800 x mm; 4 axles until 630 x mm, 5 axles until 1.650 x mm.

- Lathing centres by numerical control: 2 axles, 3 axles, 4 axles, 5 axles, with route from 250 x mm until 450 x mm.

If we centre us in the models Makino, what contribute them?

Makino Is the last of the manufacturers of machine-tool that have incorporated to our catalogue. By our experience would stand out the versatilidad of the numerical control when contributing us additional characteristics to the standard control although we work with software of extraneous programming to the of the manufacturer of the machine. They are machines that resaltan by his big robustness, that allows them work with conditions of mechanised more demanding without losing the reliability, obtaining like this some costs of maintenance reduced, no only by the direct cost of the performances but also by the reduction of stops no programmed.

To finalise, can stand out some current project or that it have supposed a technological challenge for you?

The diversity of available processes in our installations does that the challenges are continued and very shoot.

If we centre us in mechanised, the last technological challenge for Acatec was to llevar our project of OEE (Overall Equipment Effectivenes) or general Efficiency of equipment that consisted in the installation of a software for the control, gestión and monitoring of CNC in real time, for which was necessary to connect machines of distinct manufacturers, with distinct technologies and distinct controls CNC.

The big challenge supposed it the fact that each manufacturer is hermetical with the technology of his machines and hire distinct partners for the manufacture of his controls, to this it is necessary to add the fact that they offer solutions OEE only for his machines and of a very limited way. In this project was necessary to find, on the one hand, a solution in the market with able universal technology to connect with each machine, without mattering the model, the manufacturer, the year and that had the experience showed in the electronics equipment dealers equipment dealers of each one; by the another, put of agreement to distinct competitors so that they collaborated of an open and constructive way in the tuned of each one of the machines of the project.

With the cooperation and expert knowledge of our providers the project was llevar successfully.