Renishaw Ibérica, S.A.U. - Probes and dimensional sensors

OMP400

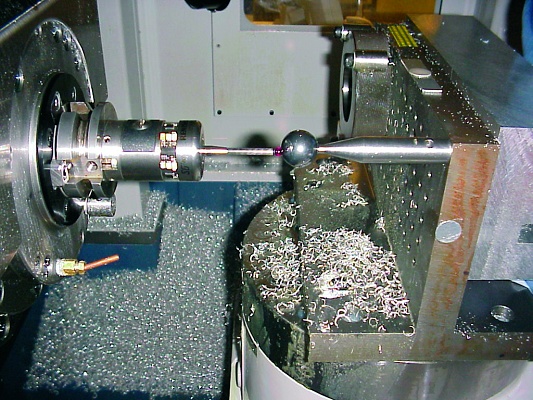

Probe ultracompacta of detection: for machining centres small

The system OMP400 of Renishaw is a probe ultracompacta of detection of effort for machining centres small, with time of reglaje reduced, lower quantity of pieces refused, lower costs in tooling, control of improved process and high precision of measurements in machine.

With some measures reduced of only 40 mm of diameter by 50 mm of length, the probe OMP400 combines the miniaturisation of the electronic components with the new advances of design of the technology of detection of effort, led by the probe of high precision MP700 of Renishaw.

By means of the technology advanced of detection of effort of Renishaw, the probe OMP400 can reach a level of precision a lot greater that the one who obtains with a standard mechanical probe, by what is the most adapted for an extensive range of applications in which it is indispensable a high precision of measure.

The galgas of effort allow that the probe can shoot with strengths of contact much lower and consistent, therefore, reduces the flexión of the palpador and the variation of trip to obtain an a lot greater precision.

Applied for the first time to the probe MP700, the technology of detection of effort is exclusive of Renishaw and offers, besides, a repetitividad improved of the probe.

The probe OMP400 has a solid design that exceeds the standard of his predecessors.

It is sealed according to the norm IPX8 to bear the surroundings of machine-tool more adverse, so that it is more resistant to the sobrerrecorrido of the palpadores and to the collisions caused by the cambiadores of tools. The length of the battery allows an uninterruptible use until 50 hours.

Thanks to his reduced size, the probe can install in the smallest machines to take advantage of the advantages that provides the high precision of the technology of detection of effort. The probe OMP400 is adapted for machines with short route of the axis Z and husillos so reduced like the HSK32.

Besides, the probe uses the system of transmission in operation of Renishaw and the new method ‘modulated', that offers a greater resistance to the interferences of the optics.

Therefore, the probe OMP400 can associate with the receptors OMM and OMI current, or with the new receptor and interface integrated cheese cheese OMI-2. It is ideal for his installation in machines that already are in operation or like a simple update of the existent probes.

The optical probe OMP400 of Renishaw is a real combination of size, precision, reliability and solidez that provides all the advantages of the inspection to a big quantity of applications of high precision.

With some measures reduced of only 40 mm of diameter by 50 mm of length, the probe OMP400 combines the miniaturisation of the electronic components with the new advances of design of the technology of detection of effort, led by the probe of high precision MP700 of Renishaw.

By means of the technology advanced of detection of effort of Renishaw, the probe OMP400 can reach a level of precision a lot greater that the one who obtains with a standard mechanical probe, by what is the most adapted for an extensive range of applications in which it is indispensable a high precision of measure.

The galgas of effort allow that the probe can shoot with strengths of contact much lower and consistent, therefore, reduces the flexión of the palpador and the variation of trip to obtain an a lot greater precision.

Applied for the first time to the probe MP700, the technology of detection of effort is exclusive of Renishaw and offers, besides, a repetitividad improved of the probe.

The probe OMP400 has a solid design that exceeds the standard of his predecessors.

It is sealed according to the norm IPX8 to bear the surroundings of machine-tool more adverse, so that it is more resistant to the sobrerrecorrido of the palpadores and to the collisions caused by the cambiadores of tools. The length of the battery allows an uninterruptible use until 50 hours.

Thanks to his reduced size, the probe can install in the smallest machines to take advantage of the advantages that provides the high precision of the technology of detection of effort. The probe OMP400 is adapted for machines with short route of the axis Z and husillos so reduced like the HSK32.

Besides, the probe uses the system of transmission in operation of Renishaw and the new method ‘modulated', that offers a greater resistance to the interferences of the optics.

Therefore, the probe OMP400 can associate with the receptors OMM and OMI current, or with the new receptor and interface integrated cheese cheese OMI-2. It is ideal for his installation in machines that already are in operation or like a simple update of the existent probes.

The optical probe OMP400 of Renishaw is a real combination of size, precision, reliability and solidez that provides all the advantages of the inspection to a big quantity of applications of high precision.