Sumalla, S.L. (División Textil) - Overflow and Jet machinery

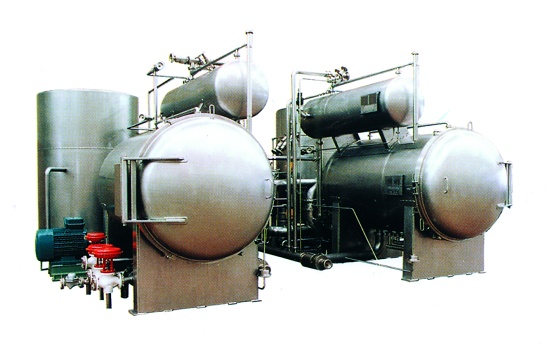

Noseda Serie TFS / TSF

Machines and integrated cheese cheese systems: for the treatment and dyed of hilados

Noseda, mark represented by Sumalla, S.L., it offers complete technological equipment to dye hilados.

The hydraulics components of all the machines to dye possess common characteristics, guaranteeing a complete hydraulics similarity. Each operator can individualizar the most adapted machine to his exigencias technological and industrial. The technology of dyed with machines HPF has been created especially for the treatment of hilados in coil of high density, microfibras and hilados continuous of low torsion. Besides it allows to increase the density and/or the diameters in the coils of hilados traditional guaranteeing the highest qualitative standards. The characteristics of the series HPF are the following: increase of the dimension of the games in comparison with an equal machine, increase of the quality, better conservation of the material, reduction of the times of procedure, reduction of the costs of production and reduction of the times of delivery of the material.

The automatic control of the capacity and of the differential pressesure offers a new perspective in the dyed of hilado in coils, copos, top and folding machines of warp. Noseda Has three different models that adapt to different exigencias. The systems allow: constant control of the hydraulics parameters, control of the modifications of the hilado during the manufacturing, adecuación automatic of the capacity/differential pressesure when changing the characteristics of the material treated, increase of the flexibility and reliability of the process and possibility of manufacturings with high variation of the density during the cycle for example in the descrudado of the silk and the decortizado of polyester in coil.

Noseda Offers also a wide range of portamateriales with bars of equal length or of different lengths, which allows to optimise the installations as well as also expand the already installed equipment in where the maximum scope of the relation productive capacity/busy surface results fundamental. The dosajes of the products and the control of pH realise with drops and high temperatures, with linear increase and with positive and negative progressions.

These machines are instrumented also with the exclusive system of Noseda Flex 10, that allows to treat, in the same machine, games of distinct capacities, keeping constant the relation of nominal bathroom. Therefore, this series allows to optimise the costs of production in each productive period, with each type of hilado and coil, and answer in immediate way to the increasingly frequent variations and sudden of the exigencias of the current market.

The production monitory and selects the parameters of work thanks to the system Datawin, a fundamental support for the users of the machines of dyed of hilados. This system allows besides guide to the operator in the election of the ideal parameters; calculate the value of the ideal and real capacity (l/min x kg), optimising the cycle time/temperature; calculate the relation of real bathroom facilitating the control of costs; analyse the characteristics of the hilado of agreement to the density of the manufacturings. It can be used with Windows.

Regarding the systems of centrifugation, exist two adaptable types to different exigencias: with monobobina or with more than a coil, each one on his bar, with cesto of small diameter or in column with cesto of big diameter. Also they have two systems of dried: with camera or with radiofrecuencia.

The hydraulics components of all the machines to dye possess common characteristics, guaranteeing a complete hydraulics similarity. Each operator can individualizar the most adapted machine to his exigencias technological and industrial. The technology of dyed with machines HPF has been created especially for the treatment of hilados in coil of high density, microfibras and hilados continuous of low torsion. Besides it allows to increase the density and/or the diameters in the coils of hilados traditional guaranteeing the highest qualitative standards. The characteristics of the series HPF are the following: increase of the dimension of the games in comparison with an equal machine, increase of the quality, better conservation of the material, reduction of the times of procedure, reduction of the costs of production and reduction of the times of delivery of the material.

The automatic control of the capacity and of the differential pressesure offers a new perspective in the dyed of hilado in coils, copos, top and folding machines of warp. Noseda Has three different models that adapt to different exigencias. The systems allow: constant control of the hydraulics parameters, control of the modifications of the hilado during the manufacturing, adecuación automatic of the capacity/differential pressesure when changing the characteristics of the material treated, increase of the flexibility and reliability of the process and possibility of manufacturings with high variation of the density during the cycle for example in the descrudado of the silk and the decortizado of polyester in coil.

Noseda Offers also a wide range of portamateriales with bars of equal length or of different lengths, which allows to optimise the installations as well as also expand the already installed equipment in where the maximum scope of the relation productive capacity/busy surface results fundamental. The dosajes of the products and the control of pH realise with drops and high temperatures, with linear increase and with positive and negative progressions.

These machines are instrumented also with the exclusive system of Noseda Flex 10, that allows to treat, in the same machine, games of distinct capacities, keeping constant the relation of nominal bathroom. Therefore, this series allows to optimise the costs of production in each productive period, with each type of hilado and coil, and answer in immediate way to the increasingly frequent variations and sudden of the exigencias of the current market.

The production monitory and selects the parameters of work thanks to the system Datawin, a fundamental support for the users of the machines of dyed of hilados. This system allows besides guide to the operator in the election of the ideal parameters; calculate the value of the ideal and real capacity (l/min x kg), optimising the cycle time/temperature; calculate the relation of real bathroom facilitating the control of costs; analyse the characteristics of the hilado of agreement to the density of the manufacturings. It can be used with Windows.

Regarding the systems of centrifugation, exist two adaptable types to different exigencias: with monobobina or with more than a coil, each one on his bar, with cesto of small diameter or in column with cesto of big diameter. Also they have two systems of dried: with camera or with radiofrecuencia.