Hommel-Etamic France, S.A., Sucursal en España (Jenoptik) - Measurement instruments (durometer, callipers, profilometers, etc.)

Hommel-Etamic Gaugeline

Dimensional control of crankshaft systems: based on optical technologies

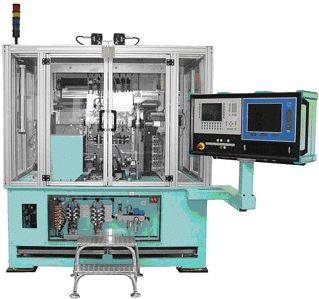

The installation is designed to inspect 100% of parts, at the end of their manufacture. Depending on the degree of automation, inspection station can charge part load manually or well is automatic.

Installation design depends on the type of part load, as well as, in the case of a load by means of robot, this is done by the upper part of the metering station. For the case of a load by means of transfer, this be done by the bottom, directly raising the piece from the transport system. The process of measurement in any case, is automatic.

The metering station is formed by inductive and incremental measurement organs, and operates according to the principle of metrology multi-dimensional. Dimensions, shape and position are determined. At the request of the customer, marking station can be integrated (ink, marked by impact or laser). If a data code is recorded in the part, this fact you can capture via camera systems and allows a single traceability of parts.

In addition to inspecting the part dimensionally, it is classified according to diameters, and recorded on the workpiece the rank or classification. Parts out of specification, are redirected to an area of rejections. The installation is ready to recalibrate automatically (according to previously defined cycle - number of parts or time.

Installation design depends on the type of part load, as well as, in the case of a load by means of robot, this is done by the upper part of the metering station. For the case of a load by means of transfer, this be done by the bottom, directly raising the piece from the transport system. The process of measurement in any case, is automatic.

The metering station is formed by inductive and incremental measurement organs, and operates according to the principle of metrology multi-dimensional. Dimensions, shape and position are determined. At the request of the customer, marking station can be integrated (ink, marked by impact or laser). If a data code is recorded in the part, this fact you can capture via camera systems and allows a single traceability of parts.

In addition to inspecting the part dimensionally, it is classified according to diameters, and recorded on the workpiece the rank or classification. Parts out of specification, are redirected to an area of rejections. The installation is ready to recalibrate automatically (according to previously defined cycle - number of parts or time.