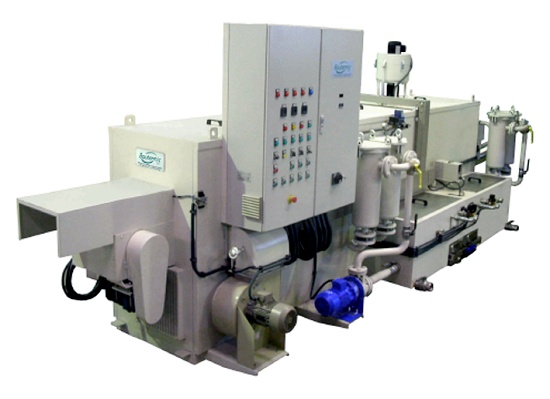

Bautermic, S.A. - Máquinas de lavado y desengrasado de piezas

Cleaning and degrease industrial: for the back setting of the pieces or for a superficial treatment of finishing

The cleaning and the degrease of pieces of rational and industrial form initiated at the beginning of the century happened because of the need to have of big quantities of pieces that had to manipulate perfectly clean, well was for his back setting or for a superficial treatment of finishing (electrochemical treatments, painted, plastificado, etc.).

The constant advances have done that this type of machines happened to be a complement accessory, almost manual and uneconomic, to turn into authentic automatic cells of indispensable production nowadays, to obtain the volume and the quality of manufacture wished.

Like the cleaning is the absence of substances no wished on a determinate surface, of what treats the industrial cleaning is to delete said substances contaminantes, as they are: the dust, rests of shavings of the mechanised, oils, fats, oxides, desmoldeantes, between others.

In front of the need to have to clean a determinate type of pieces, the first that has to determine is the degree of cleaning or degrease required, matizando the final state in which they have to remain the pieces, fosfatadas, decapadas, pasivadas, or with only a cleaning of intermediate type, wet, dry, blown or aceitadas, etc. And if it treats of an absolute cleaning, marking besides the maximum percentages of granulometry and admissible superficial gravimetry.

-Factors that influence in the degrease and cleaning.

Type of cleansing agent:

- By means of dissolvent organic, mineral, in liquid phase, steam...

- By means of aqueous solutions with alcaline detergents.

- By means of emulsions of dissolvent type oil, nafta, white-spirit;

in half aqueous.

- By means of immersed ultrasounds in liquid phase.

Factors that influence in the methods of cleaning:

- Form, size and weight of the pieces .

- Manipulation, form of load and download.

- Back operations: Galvanised, painted, thermal sensors treatment.

- Production.

Factors that influence in the election of cleaning products:

- Nature of the pieces (Faith., To the., glass, plastic...).

- Type of dirt to delete, quantity, complexity, adherencia .

- Final state required (intermediate cleaning, wash calibrated, aceitado,

dried...).

- Maximum temperature of utilisation allowed.

- Form in that it realises the cleaning: by immersion, projection, agitation …

Factors that influence in the election of a system of cleaning:

- Production, volume and weight of the load.

- Nature and quantity of the contaminantes to delete.

- Composition of the material (metal, plastic...).

- Form of the pieces (curvadas, with holes pasantes or blind, unseen

surfaces....)

- Cycles of necessary work (wash, enjuague, pasivado, dried...).

Factors that influence for the election of a machine:

- Method of cleaning (static, continuous, intermittent...).

- Production (seriada, diverse pieces...).

- Degree of automation (with or without hand-held need of work).

- Space and available energies.

- System of cleaning (aqueous, with dissolvent, ultrasounds...).

- Price of acquisition and maintenance.

- COMPLEMENTOS OF AUTOMATION To TAKE INTO ACCOUNT:

- Decanters separadores of oils, shavings and fangos.

- Automatic filters and extractores of slimes.

- Dosificadores Of products detergents.

- Condensers of vahos.

- Recycled and depuración of waste water...

By all the exposed, understands that for each type of piece to clean, as it was the production, size, weight, degree of automation wished, etc., can use different types of washing machinees:

Thus, to choose the best or more economic solution, is necessary to have good knowledges on these matters or attend to a skilled company, since they can be valid diverse solutions, some simpler and at the same time economic, other more sophisticated and automated that they can save space, hand of work, consumables power, water, detergent, electricity… To end of rentabilizar to the maximum the processes for the cleaning and the degrease industrial.