Transdiesel shown in Smopyc of John Deere equipment

on March 21, 2011

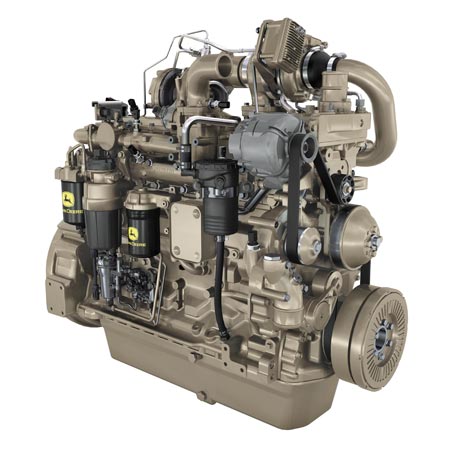

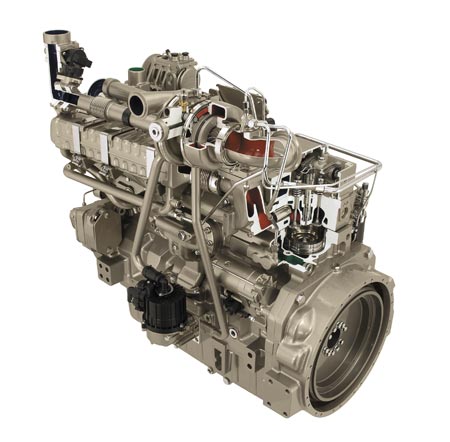

The date of effectiveness of Tier 4 provisional rules / phase III (b) for engines of 56 kW (75 HP) to 130 kW (174 HP) is January 1, 2012. For engines that develop from 56 kW (75 HP), John Deere will begin its platform PowerTech Plus Tier 3/stage III A six-cylinder in line - that includes a (EGR) cooled exhaust gas recirculation system for the control of NOx - and the addition of a filter of escape for the reduction of emissions of PM particles. These engines have fully electronic regulation, 4 valves per cylinder stock, injection of high-pressure, supercharger and cooling after air-to-air system.

The engines of less than 130 kW (174 HP), will be available with with cubic capacities of 4.5-6.8 litres and will be equipped with distributor with valve discharge or of variable geometry, depending on the size of the engine. Compared with drivers John Deere of larger size, the engines of less than 130 kW (174 HP) will incorporate smaller exhaust filters, they may be mounted in the engine or other locations to provide greater flexibility. Engines of this category of powers be used for active regeneration a dosing system in cylinders, while John Deere engines with powers above the 130 kW (174 HP) will use an external dosage system. Engine John Deere of more than 130 kW (174 HP) will be proposed with with cubic capacities of 6.8; 9.0-13.5 litres.

· PowerTech PWX 4, 5 L: 56 kW - 91 kW (75 HP - 122 HP)

· PowerTech PVX 4, 5 L: 93 kW - 129 kW (125 HP - 173 HP)

· PowerTech PVX 6, 8 L: 104 kW - 129 kW (140 HP - 173 HP)

· PowerTech PVX 6, 8 L: 138 kW - 187 kW (185 HP - 250 HP)

· PowerTech PSX 6, 8 L: 168 kW - 224 kW (225 HP - 300 HP)

· PowerTech PVX 9, 0 L: 187 kW - 224 kW (250 HP - 300 HP)

· PowerTech PSX 9, 0 L: 242 kW - 317 kW (325 HP - 425 HP)

· PowerTech PSX 13, 5 L: 298 kW - 448 kW (400 HP - 600 HP)

EGR and VGT technology

John Deere has been the leading supplier of engines in use successfully technologies of recirculation of exhaust gases refrigerated (EGR) and distributor of variable geometry (VGT) in applications for off road, introducing them into their engines type-approved under the rules of emission Tier 3/stage III A. Since then, John Deere has accumulated many hours working out of road with these technologies, and has established a proven record of reliability.

With its engines interim Tier 4 / stage III B 56 kW (75 HP), equipped with cooled EGR and VGT, technologies John Deere expects to maintain similar to their Tier 3 engines fuel economy standards/phase III A. John Deere with cooled EGR engines work effectively with diesel fuel with low sulphur content, as well as mixtures of biodiesel, owners and operators to provide optimal performance and flexibility of choice of fuels.

Choice solutions to Tier 4 provisional regulations / phase III B, John Deere dismissed the selective catalytic reduction (SCR). The solution of John Deere take the cooled EGR systems and exhaust filters provides original equipment manufacturers and end users a solution demonstrated with the best total economy of fluids. The use of the EGR system and a single fluid means that owners and operators will not have to face the cost of the diesel fuel over the additional cost of the fluid to escape (DEF) systems requiring SCR systems. "In terms of standards interim Tier 4 / stage III B, we are not only looking for the best fuel economy, we are taking into account the total consumption of fluids", said John Piasecki, global director of marketing, sales and service customer JDPS.

In addition, cooled EGR solution management does not require the intervention of the operator. It must not afford the cost and complications of a second fluid. The SCR system can be an appropriate technology in the future, it is most developed for applications outside of road; However, it is not necessary for Tier 4 provisional legislation / phase III B. "cooled EGR system and exhaust filter are the simple and proven solution requested by our clients," says Piasecki. "We believe that the cooled EGR provides our customers the best value for the Tier 4 provisional rules / phase III B".

The optimization of the size of engines

John Deere has optimised the size of his motors Tier 4 provisional/Phase III B. All the motors John Deere with EGR refrigerated and filter of leakage will occupy a similar space to the of the motors Tier 3/Phase III To with silenciadores of leakage to which substitute.

John Deere is one of the few manufacturers that designs motors and machinery of construction, forestry and agricultural, what provides to the mark an experience in the adaptation and integration of the engine, the transmission, the filter of leakage, the group of refrigeration and the unit of control of the engine (ECU) to achieve the maximum efficiency. This integrated process improves the performance, the comfort of the operator, the economy of fuel and the total value of the products John Deere and of the products of other manufacturers instrumented with components John Deere.

The motors of less than 56 kW (75 CV), that include the motors John Deere PowerTech M and PowerTech And 2,4L, carry in production from the year 2007 and already fulfil the rules of broadcasts Tier 4 provisional and Phase III To. The motors PowerTech M of 2,4 litres mount butts of 2 valves by cylinder, systems of injection with mechanical pumps and turbocompressesors of fixed geometry. The motors PowerTech And of 2,4 litres share the butts of 2 valves by cylinders and turbocompressesors of fixed geometry, but add regulation totally electronic, injectors of electronic unit and enfriadores back air-to-air. Any of these motors demands the employment of EGR refrigerated or of filters of leakage.