This news article was originally written in Spanish. It has been automatically translated for your convenience. Reasonable efforts have been made to provide an accurate translation, however, no automated translation is perfect nor is it intended to replace a human translator. The original article in Spanish can be viewed at

Entrevista a Noel Hugo Carlos, jefe de producción de TecnimoplásInterview with Noel Hugo Carlos, head of production of Tecnimoplás

"The idea is to make molds from 6-10 weeks depending on the size and complexity"

How many people work in the company? when was created?

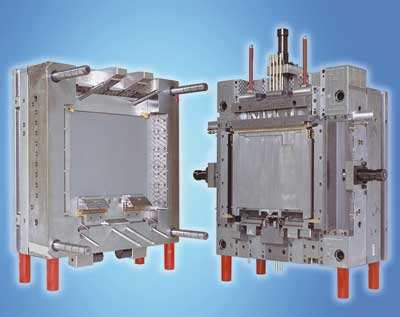

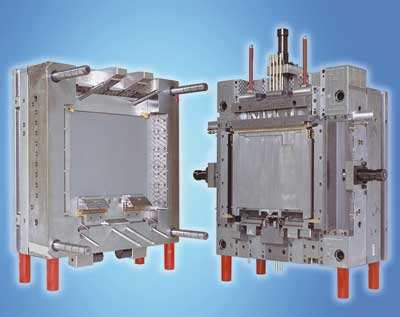

Tecnimoplás, Indústria technique of mould LDA., is a company established in the moldista industry since 1971, in the area of Marinha Grande. We design and produce moulds from precise steels for plastics of a maximum size of 2500x industry 1600 mm and 15 tons. The "know-how" of 80 skilled workers and the most up-to-date technology positions us in the leadership of Portuguese companies.

What kind of moulds are manufactured?

Major markets are the automotive industry, storage and household appliances. Specialists in molds of flats, moulds 2 K, gas injection moulds, mould of cored and moulds of multicavidades. End-users are original of Netherlands, Sweden, France, Spain, Germany, England, Switzerland, Israel, Saudi Arabia, USA, Brazil, Argentina, Colombia, Venezuela, Peru, Guatemala

There are many differences between the requirements of quality of the customers of each sector? What make the difference?

All (normally companies injectors) customers are looking for partners in the moldista sector to find economical solutions. This means a mold made in the shortest time that fits in the smallest fuel transfer, good quality and a precise mould, with a short cycle, with a simple maintenance and finally, in a competitively priced. By the customer of the automotive industry and household appliances customer demands the same and Tecnimoplás they have exactly the same treatment.

What has been the evolution of the industry and your company during the last years?

At the beginning of the Portuguese moldista industry we vendíamos moulds based on workers with low salaries and low level technology. This situation continued for decades, but during this time, the best companies have retained "know-how", equipment and expertise to manufacture molds complexes. Since the quality of the Portuguese molds have increased and improved based on the "know-how" and experience of employees, their salaries have also been increasing over the years. Today the wages are very high in comparison with Asia.

That is why today we cannot compete with Asia in what refers only to the manufacture of moulds. We must develop new capabilities based on new technologies and innovation. Today the challenge is not only produce the mold, but that the most important thing is to seek solutions using our knowledge and experience. Tecnimoplás and other Portuguese seamstresses are changing its internal structure; Today the Department of CAD/CAE/CAM has more staff compared to the production, exactly as opposed to at the beginning of the moldistas industries. We are also buying new machines because they are more accurate and quicker, and selling old machines.

What threats or difficulties faced by the sector today?

The main threat is Asia. With Korea we have the same prices and higher production cycles; to compete with that country we are reducing the production time and using the advantage of being close to Europe (less time for transport). With China we compete not directly because they are using price as its main attraction, something with which we can not compete. The only solution to compete with China is to make high-quality molds.

Portuguese moldistas industries are working with customers and partners from the beginning of the development of the product. This service can be developed by companies with "know how" such as the Portuguese moldistas.

It is very important to reduce production cycles so you have to change the working day from 7.00 to 24 hours. The idea is to make molds from 6-10 weeks depending on the size and complexity.

It performs all the machining or subcontract part?

We offer complete solutions to the internal client.

It also carries out engineering? What technical and human resources does?

Milling machines with high-speed France (Huron) and Japan (Mori Seiki), CNC milling machines of Spain (Anayak).

Switzerland (Agie) wire EDM machines.

Machines of EDM by penetration of Spain (Ona) and Switzerland (Agie and Charmilles), Germany (Ixion) drills, lathes of Japan (Mori Seiki), presses of adjustment from Italy (Millutensil).

It also carries out engineering? What technical and human resources does?

Our projects Department is composed of six engineers (mechanical, and specialized materials) and seven designers of moulds. The Department of CAE employs software Moldflow CAD Department develops 3D with Unigraphics, Solidworks and Mouldworks mold design. We also have Autocad 2004 for further production. The Department CAM - milling machines with WorkNC (Automatic Complex Surface Machining) and CamWorks.

He also built special moulds?

Specialized in mould of flats, by gas injection moulds, moulds of cored and molds multicavidades.

Has also injectors for testing of injection?

Currently we have no injection machines. We are looking to invest in this equipment. There are currently several companies specializing exclusively in testing of injection.

For which geographical markets do they work? how much is spent to Spain?

Netherlands, France, Spain, Germany, England, Switzerland, Israel, Saudi Arabia, United States, Brazil, Argentina, Colombia, Venezuela, Peru, Guatemala

Tecnimoplás has a long tradition in countries of Eastern Europe, but taking into account the value of the dollar (currently 25% less than the euro) we have to base our business on European countries. We are looking for new customers in Europe, mainly in Spain (by proximity), but the process may take a year to learn about the market and find new customers. For this reason, the year that comes this percentage will grow, I hope.

How was the last year for the company?

We have reduced the volume of sales by 20% up to four million euros. The main reason is the competition with Asian, European recession and the low value of the dollar. The volume of work was the same but the prices were lower. Now we are transforming our company to adjust costs to the new reality.

Where you think that you must move a company like yours to improve business?

We are currently in full "revolution". Thanks to the new communications world is very small; our competitors can only be served by telephone or computer, therefore we must take advantage of being in Europe and show our customers communication is simple, the distance for the meetings is less and the time and cost of the displacements are small compared to Asia.

Now, we must use innovation, knowledge and new technologies to develop complex products, not only the transformation of steel in a mould.

We are also making changes in the company to reduce delivery times.

Related Companies or Entities

Dassault Systèmes España, S.L. - SolidWorks

Hexagon Production Software