HMI Native on the platform iPad

Joan Lluch Zorrilla, founder of

Already is possible interactuar with a PLC (or miscellaneous) directly in an iPad without the need of a server intermediate web. Up to now virtually all the solutions that existed to visualise data of programmable robots (PLC) on mobile electronic tablets were based in web technology or of remote desk. The web applications have seated a tendency in the last years —possibly because it treated of a technology of low cost already existent— but the reality is that this type of solutions hardly presents a degree of optimum efficiency. The fault of provision is been due to a crowd of factors that derive of the execution in some surroundings —the browser web— that never was thought for monitoring of data in real time, and to the forced need to have of a ‘server web' or another device of hardware that mediate between the PLCs and the electronic tablets. When it treats to represent information using an iPad, the technology used conditions to a large extent the final result that can expect, so much from the functional point of view like aesthetic-visual. It is not surprising that a company like Linkedin replaced does a time his ancient web application by a totally native application. The difference is more than remarkable. Apply the same concept in the field of the interfaces man-machine (HMI) for electronic tablets provides clear advantages.

The system HMI Pad

The new system HMI Pad of SweetWilliam for the platform iPad of Apple breaks with the existent diagrams to date, when having been designed from the beginning like a native application. It contributes a series of characteristics that are not near at hand of the traditional solutions, based in web. HMI Pad Positions like the most adapted platform in those cases in which it prevails the experience of the user and does not want to or can depend on servers or intermediate hardware to have of an advanced interface man-machine of high provision on the devices iPad of Apple. The iPad of Apple with HMI Pad installed is an alternative to the classical tactile panels that contributes functionality, mobility and suitability. Using one of the protective available in the market, the group turns into even more robust that a lot of classical screens of signpost.

In the following table enumerate some of the important differences that characterise the platform HMI Pad in relation to the systems based in web:

| HMI based in Web | HMI Native (HMI Pad) |

|---|---|

| Efficiency conditioned to the availability of big bandwidth, and to the provision of the browser. The application is monoproceso (single-thread). | Application entirely multiproceso (multithread). It is designed from the base with the aim to achieve the maximum efficiency and speed. It is then , substantially distinct, in this appearance, to the rest of solutions. |

| Interfaces based in ancient designs already existent, in occasions little flexible or with limitations. | Interface of better user and more adaptabland to special needs. Excellent experience of the final user. |

| Interactiveness limited, sometimes even with scarce realimentación of the actions of the user. | Immediate answer to actions of the user or changes in the PLC. |

| Depend on a PC, or another intermediate device, generally of an only manufacturer. | Direct communication with the automatons. Do not need intermediate devices. |

| Do not take advantage of the technical characteristics or the own visual styles of the mobile device. | Bears the sensors of the iPad: of acceleration, gravity, geolocation, rotation of the device, as well as the provision multi-touch, recognition of gestures, and the standard controls of the mobile device. |

| The complete solution requires multiple components of hardware and software. | Needs an only component hardware: an iPad. |

| Difficult or committed hygiene. Only possible to the level of the browser web. | hygiene implemented to all the levels. |

| Difficult control of updates particularizadas and of personalización of projects. Philosophy of the coffee for all. | Implementation and simple update of projects in devices of customers or particular users (with a simple ‘tap'). |

A machine or a plant of process can be monitored or controlled directly from an iPad thanks to the application HMI Pad.

Components of the system HMI Pad

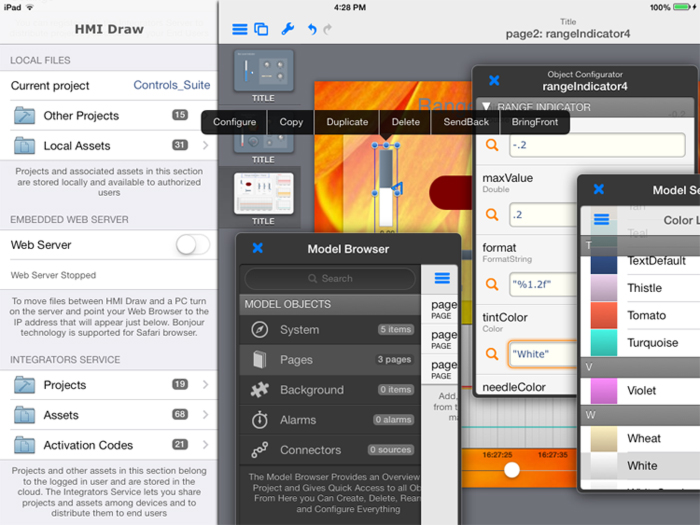

The system HMI Pad consists in three components of software: HMI Draw, HMI Pad Service and HMI View.

| HMI Draw | it is the program (app) that allows to the integradores of automation or manufacturers of machinery develop projects of interface man-machine directly in an iPad. |

|---|---|

| HMI Service | it is an available server in the cloud that allows store projects HMI with his archives associated (for example images). The projects stored can be implemented in-line to the customers or final users. |

| HMI View | it is the application used by the final users for execute the interfaces HMI developed specifically for them. |

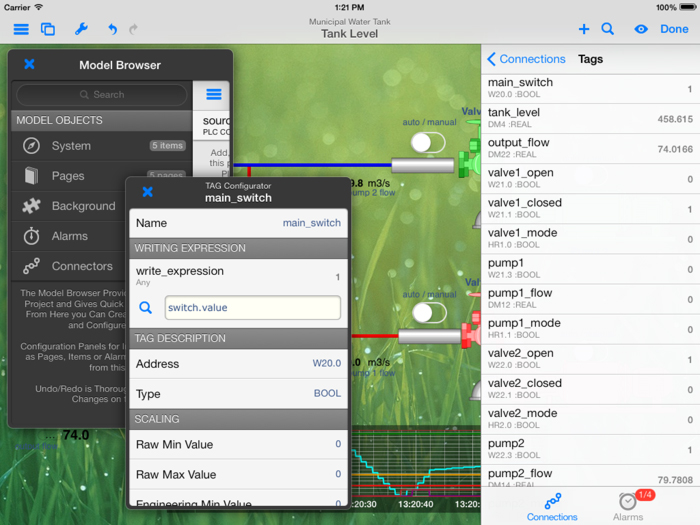

The surroundings of development

The interfaces HMI on HMI Draw build to base to create pages and add visual elements or other objects in pages. The objects connect between himself or with the variables of automatons by means of expressesions. Virtually all the objects can connect between them by means of expressesions —or mathematical relations— of an analogous form to the cells of a leaf of calculation. The project HMI executes finally of native way in the iPad, no through a browser web. This architecture, extremely powerful, provides some fantastic surroundings for the creation advanced of HMI.

The surroundings of development offers complete functionalities for the edition of projects. It is possible to copy/hit/duplicate elements, pages, variables of PLC, connectors, etc. individually or in group, even between different projects. It has in addition to boundless capacity to undo/redo that it extends to all the actions of the process of development.

HMI Pad Uses different elements and his connections for modelar the systems that allows to supervise.

Conceptually, the process of creation of an interface HMI with HMI Draw seems to the of creation of a leaf of calculation, except that instead of connecting cells connect the properties of objects, and that the engine of expressesions of HMI Draw allows much more. All the process of development is consistent with this simple principle to connect objects and, therefore, is very easy to learn. The application provides realimentación immediate of any action and even continues updating values in real time during the way edition.

The subsystem of expressesions bears all the types of common data, including 'strings', 'arrays' of any type, and arrays asociativos (dictionaries). The syntax is based in the language of high level Ruby and bears an important subset of the same which provides an unprecedented functionality in the field of the HMIs.

The integradores advanced can choose export his projects in an archive of text and do changes in an editor of standard text to matter them again to the application.

The application is compatible with the PLCs of the main American manufacturers, Europeans and Japanese including: Allen Bradley, Mitsubishi, Omron, Opt22, Schneider Electric, Siemens, Wago and Beckhoff. The controllers of communication use the protocols of native communication of the manufacturers and are highly efficient.

The subsystem of communications employs technicians advanced of agrupamiento of variables and optimisation of the plots of communication by means of the calculate automatic of the conjoint minimum of necessary commandos to complete a cycle of reading. Also, of exclusive way the application commissions to determine at all times cual is the minimum group of variables that is necessary to communicate to keep the integrity of the interface, without that in any moment effect requests of reading that are irrelevant for what is visualising .

The system of development allows a personalización graphic complete of the model, that helps to the user to identify his correspondence with the real objects that represents.

Remote implementation of projects

The projects and other archives related can store in the 'cloud' by means of the integrated service HMI Pad Service which facilitates the installation of interfaces HMI to final users and his back maintenance without need of physical presence.

The procedure bases in the creation of codes of activation that once delivered to the customer or final user allow the automatic download of the projects associated. It guarantees the privacy and conservation of the 'know how' of the integrador by means of the transmission and storage enciphered of the projects in the electronic tablets of the final users.

Cost

The system HMI Pad has an especially competitive cost. The applications

The projects enable for his installation in iPads of final users by means of the purchase of codes of activation. The price depends only of the number of installed projects in iPads of customers or final users; between the €130 by a simple activation and the €72 by the activation of a project in 10 tablets.

Competitive advantages

- Immediate answer to the actions of the user and excellent interactive experience. Complete integration with the characteristics of the mobile device (iPad).

- Connects directly with automatons (PLCs)

- native and direct Support of the main marks of automatons.

- High reliability and hygiene.

- Easy to use.

- Remote installation of projects in devices of final users with a simple 'pulsación', saves costs of installation and travel.

- An iPad of Apple can replace to traditional tactile screens to a very inferior price. It does not need any additional hardware. Application 100% native for iPad

- The total mobility provides advantages to his users.

- Cost of entrance extremely low, does not pay until the project installs in the iPads of the final users.