‘Kinetic Rain', the simbiosis perfect between the technology and the art

“The harmonious interaction go in more than one thousand drops also symbolises the a lot of people that day in day out commission that the travellers and the visitors of the airport Changi remain positively surprised and remember it with like”, comments Yeo Kia Thye, vicedirector of operations of airport of the Changi Airport Group.

The installation, composed by two fields interrelated with 608 drops each one, covers a total surface of more than 75 square metres and reaches a height in the enclosure of more than 7,3 metres. The artistic concept of this little usual installation is of the agency Art+Com of Berlin. The technical realisation of the complete project and the programming were assumed by the MKT AG of Olching, near of Munich, Germany. For the programming and the realisation of the system of control, this skilled company in kinetical installations had the support of Beckhoff. “With ‘Kinetic Rain' have realised the most demanding project of this type of our history”, comments Axel Haschkamp, member of the managerial board of MKT AG: “In this project invested more than 2.000 hours of work of engineers. One of the most special challenges was the transport until Singapore of the installation of 30 tonnes, entirely smart”.

The precise movement of 1.216 axles posed requirements extremely elevated to the system of control of ‘Kinetic Rain'. Besides they were necessary a high availability, a form of compact construction of the components, as well as the replacement of components without direccionamiento. “One of the most important conditions of our customer, the airport Changi, went that the installation worked during the 24 hours of the day. Although an individual axis fail, the show has to continue”, adds Peter Haschkamp, also member of the managerial board of MKT.

How they control 1.216 axles of form synchronised?

“The movement synchronised of 1.216 axles is one of the most stood out points of this project”, stands out Raphik Shahmirian, of the department of sales of Beckhoff in his headquarters in Munich, the one who was manager of the technical realisation of ‘Kinetic Rain' in narrow collaboration with MKT. Besides it had to fulfil with high requirements of dynamics, precision and speed of the movements. The drops move with a speed of 1,5 m/s and an acceleration of 1,4 m/s². The movement has to be dynamic and at the same time continuous and not presenting any type of shakes. MKT Found the solution for this task in the platform of control of Beckhoff based in PC and EtherCAT, with compact technician of servoaccionamiento.

An industrial PC head office of type C6525 commissions of the control. This communicates with the computer GUI special of MKT through TwinCAT ADS. Simultaneously, the computer controls the 1.216 axles centralmente through TwinCAT NC PTP and acts like teacher. Through the function of disks of levy, the master computer coordinates the distribution of the data of position in the six computers slaves, each one of which have assigned 192 or 208 axles respectively, and commissions of the synchronisation of all the axles by means of fixation of a master axis like reference (see the chart). The communication takes place in real time through EtherCAT until the accionamientos. The computer GUI of MKT serves for the visualisation, but also contains the show in shape of a table, where find determined the data of position of each drop, at intervals of 200 ms. This corresponds to five images by second. The movement without shakes and perceived like continuous by the human eye, generates by means of interpolation in TwinCAT NC PTP. Here they calculate respectively 100 intermediate positions for each drop using an algorithm Spline in a task NC of 2 ms. These calculations take place in each computer slave for the local axles that were him assigned.

The artistic intention to move the drops of form synchronised in a species of film 3D only is possible by means of the use of EtherCAT and TwinCAT NC PTP. Whereas the teacher keeps all the axles synchronised between yes, the computers slave calculate each 2 ms the positions of the axles that were them assigned and communicate them in real time to the servoaccionamientos through EtherCAT.

Servoaccionamiento Compact in terminal of 12 mm

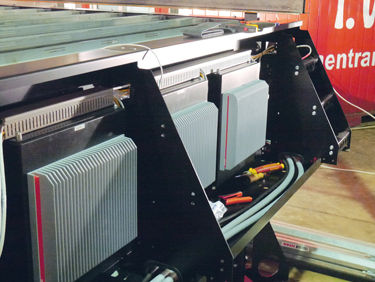

The accuracy of movement of the individual axles is extremely precise and reaches a value of 1 mm, for a total length of 7,6 m. The desfasaje maximum between two drops is of 0,25 mm. Each drop is controlled by means of a terminal of servomotor EtherCAT THE 7201 and a servomotor of type AM3121. “With the servoterminales, that situate impecablemente in the stretch of terminals EtherCAT, have found an extremely compact solution, that fulfils perfectly with the constructive conditions for a space of setting limited in the ceiling of the building”, stands out Peter Haschkamp. The technology of the servoaccionamiento offers besides dynamic advantages and allows continuous transitions.

The modularidad of the system of control facilitates the set up

“For us also were important the modularidad of the solution of the system of control and the fact that an individual axis can substitute without direccionamiento. This allowed, for example, a set up partial, that is to say that we could work simultaneously in the software, the hardware and the mechanics, what allowed us fulfil with the short period of time of the that had for this project”, stands out Peter Haschkamp. TwinCAT NC PTP Allows besides “move” by the complete show, that is to say, can advance or retreat as in a film. This also has simplified a lot the set up for MKT. If an individual passage of the “film” was not 100% satisfactory, the engineers of MKT had the possibility to go back to repeat it one and again. A big advantage, as it stands out Peter Haschkamp: “other solutions do not allow it, by what one is forced to leave to run the show every time from the beginning until arriving to the position wished, what requires a lot of time”.

Unlike other comparable kinetical sculptures, realised by MKT in the past through systems of control of hardware decentralised, ‘Kinetic Rain' is controlled by means of software and a central PC and transmitted by means of EtherCAT. The function of disks of levy, that in solutions of previous control of MKT found situated locally in the amplifier of accionamiento, now is realised by the software. In this way, the data of position are managed centralmente and distributed through EtherCAT in real time to the axles.

Another important appearance for MKT in the election of Beckhoff like partner was the global presence of the company in the market. Thanks to this, Beckhoff could accompany and support the project no only through his experts in the head office of the company in Verl (Germany), but the support and the technical service also were guaranteeed locally, beside the final customer, through the headquarters of Beckhoff in Singapore.