SolidWorks plastics: The mechanical design is not alone metallic, is each more plastic day

During the past year, SolidWorks announced the availability of SolidWorks plastics. The product is not the fruit of a long process of internal development, but it treats , in this occasion, of an adaptation of the software SimpoeWorks of the French Simpoe. Like this, it achieves split of a mature product and tested, add the experience of a company devoted almost in scoop to the simulation of the injection of plastics and go out to the market with the maximum guarantees.

The key points of SolidWorks plastics

- One very wide database of plastic materials, with all his properties. More than 4.000 materials, easily personalizable.

- A wide range of capacities of analysis

- The capacity to guide to the user in the approach of the analysis and the interpretation of the results

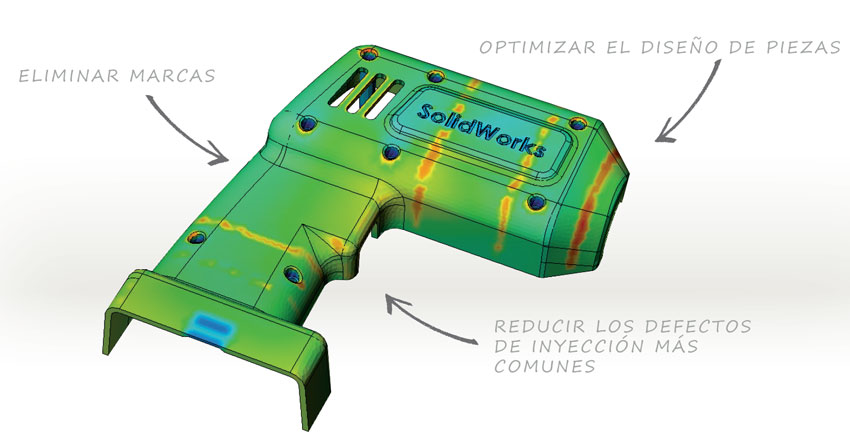

For the designers of pieces, allows:

- Answer to the basic questions:

- The mould will fill ? The piece is really inyectable?

- Where will produce the lines of welding?

- There will be bubbles of air?

- Simulate the filled of the mould

- Optimise the form of the pieces to facilitate his manufacture

- Determine the optimum points for the injection of the material

For the designers of and manufacturers of moulds:

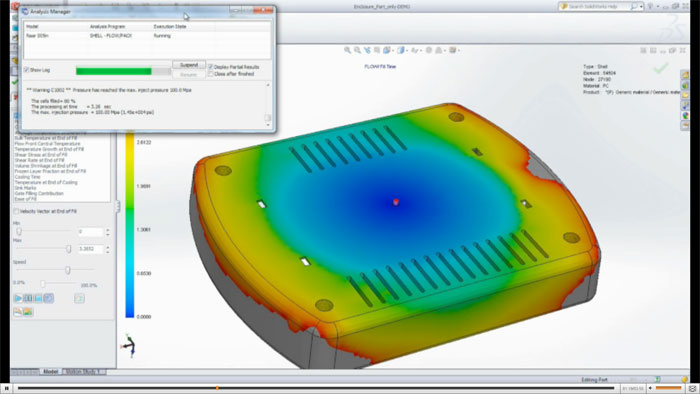

- Simulate the filled and compressesion of the mould

- Optimise disposals of one and multiple cavities

- Balance systems with multiple moulds

- Determine the pressesure of necessary injection and the strength of necessary closing of the inyectora

- Analyse and simulate sophisticated conditions: sobremoldeo, moldeo two-phase, moldeo aided by gas, valves, ...

The competitive advantage of SolidWorks plastics: the software are not only programs, also is service

Obviously, the second advantage is the complete integration inside the surroundings SolidWorks.

Available versions

SolidWorks plastics Professional

SolidWorks plastics Professional allows to perfect the feasibility of manufacture of pieces of plastic injected in the first phases of the process of design. It treats of an easy software to use and learn and that is integrated cheese cheese to the complete with the surroundings CAD of SolidWorks, what allows to analyse and modify the designs at the same time that perfects the form, the adjust and the function.

SolidWorks plastics Premium

SolidWorks plastics Premium provides to which design or manufacture moulds of injection a way to optimise them precise and of simple use. It allows to create and analyse with rapidity moulds of an only cavity, of several cavities and even families of moulds, including channels and entrances of injection. Even it can balance systems of channels and calculate the length of the cycles, the strength of closing and the grammage of injection. In summary, allows to optimise the design of the system of feeding and avoid the high cost to have to retouch moulds.

The prices of reference (in EE UU) are: 4.995 USD for the professional version, and 14.995 USD for the Premium.