Practical cases of tuned of lathes and rectificadoras

The first part of the evento was centred in the technology of dynamic measurement without contact where employ optical telecéntricas with a source of light infraroja/green and cameras CCD of high resolution, key to measure pieces with tolerances of micras, in question of seconds. Hommel-Etamic Carries more than 20 years developing and perfecting this solution with big success.

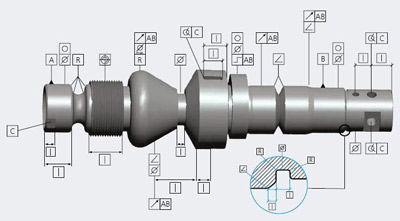

Is possible to verify dimensions (radios, lengths, angles, etc.), forms (runout, cilindricidad, concentricidad, parallelisms, conicidad, etc.), profiles (levy or CAD), etc. (see image 3). All this provision, besides in question of seconds.

Allows to save until 80% of the time with regard to traditional systems of measurement by coordinates (CMM – three-dimensional), projector of profiles, etc. The pieces type for this instrument are primary axles, tree of levy, crankshaft, valves, pieces bar-cutting. Also it is possible to measure pieces of very reduced size like dental implants.

The load of piece realises between centres, which through a system of engine-encoder turns, and in the long of the same displace both cameras telecéntricas (CCD) that register dynamically the profile of the piece in his 360º. His robust construction is thought to implant in a hostile environingingment of production to 3-5 turns.

The most common applications are so much of final control of pieces, how instrument of reference for the adjust and tuned of processes of manufacture (rectificadoras and/or lathes). It is reseñable besides, the flexibility of the instrument, since the change of a piece to measure another is question of seconds.

Division of Industrial Metrology

In the field of the industrial metrology, Jenoptik is a manufacturer and provider of solutions of metrology of manufacture of high precision with and without contact. Hommel-Etamic Is the division of Industrial Metrology of Jenoptik. The range of products and services includes complete solutions for a wide variety of tasks of measurement, such as the measurement of rugosidad, outline and form-position, as well as dimensions in piece no finished or final control, so much in production as in the laboratory of metrology. Our wallet of products complete with a wide range of services of quality consultancy, learning and assistance, that include agreements of maintenance. Jenoptik Realises besides measurements of pieces for customers and issues certificates DKD of calibración of patterns/instruments.