Siemens, S.A. - Smart Infrastructure - Software for the metalworking industry

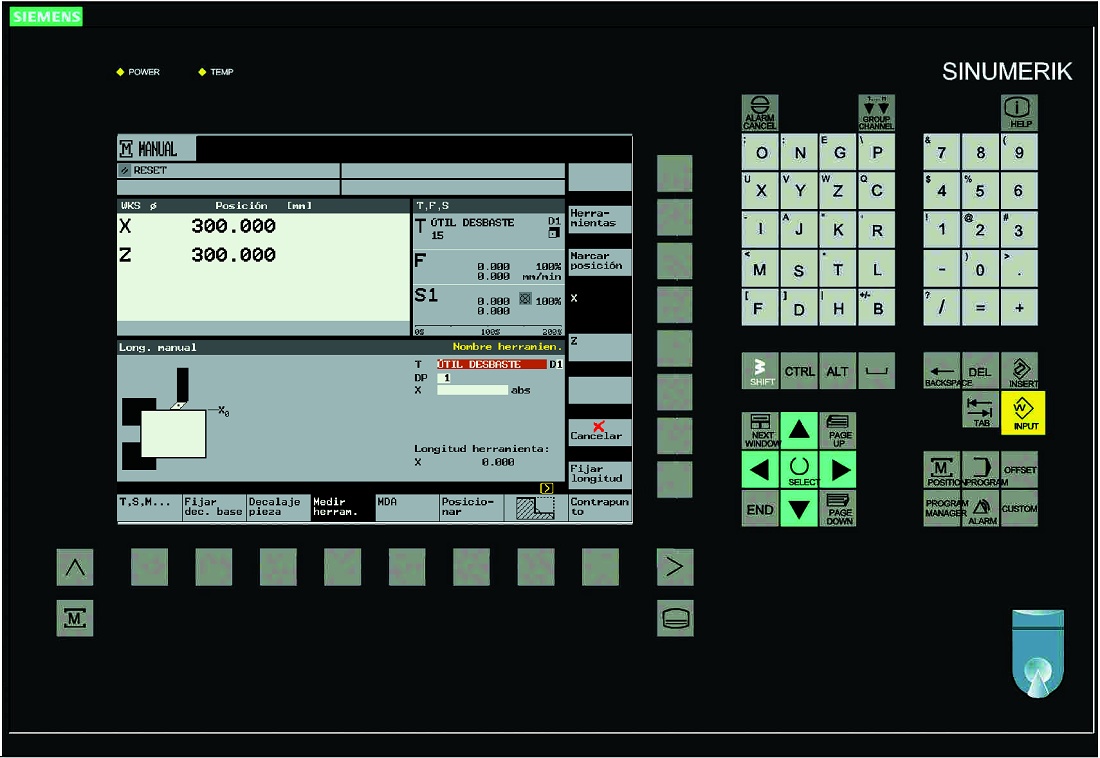

Siemens ShopTurn

Programming for lathes: greater production

In addition to the already known systems of programming had a conversation ShopMill for fresadora and ManualTurn for lathe, Siemens complete his range of conversational with the new ShopTurn, with own functions of fresadora in lathes with motorised tool.

Milling with ShopTurn.

ShopTurn No only allows to do the classical operations that can do with a motorised tool in a lathe, but besides it allows to program in our lathe even cashiers with islands in the frontal of the piece. This achieves that our machine was much more productive, since operations that had to finish in a fresadora can llevar directly on the lathe, with the big saving that this supposes. All this programmed on some conversational surroundings that does very simple his programming.

The operations that can llevar in a fresadora can now also realise on the lathe thanks to his interpolation between the axis X and the axis C thanks to the ShopTurn. For this also has of the most common cycles of milling for greater ease of handle, like cashiers, vástagos, slots and milling poligonal (to do a hexagon for example). Also it can mill with the tool motorised the surface of the cylinder programming in 2D.

Turning with ShopTurn.

Besides, the functionality of turning is studied cuidar all the details, allowing even the classical operations of desbastado, ranurado, throats, tronzado, threads and review of threads, can program directly the counterpoint, the tray of pieces and the loaders of bars and even a second cabezal, whenever the machine was prepared for this.

The cycle of desbastado is optimised to the maximum, allowing define the piece in the rough to desbastar of 3 different ways, like cylinder, like demasía of outline (for pieces of smelting) or defining we the form of the piece in the rough that we want to desbastar. Of this way save time of mechanised to the not mechanising in empty.

Also in the desbaste can desbastar the piece with a tool whose angle does not allow us realise all the desbaste, and afterwards, with another different tool. The control recognises automatically the residual material that remains without mechanising and finishes it with another tool. This is not exclusive of the cycle of desbastado, but the cycles of ranurado also can detect the residual material to use distinct tools.

Goratu With ShopTurn.

So much the ShopMill like the ManualTurn already are a classical in the models of Goratu, and from does time already offers in his model of bancada bent GST4 the ShopTurn of series. Of this way, Goratu offers with each machine the solution of suitable programming for each need in workshops of mechanised.

The simulation 3D of ShopTurn.

ShopTurn Offers a powerful simulation 3D with possibility to realise a cut to be able to see in 3D the mechanised inner of the piece, as well as rotar the piece 3D in the space with the cut chosen. Besides his representation in screen is own of authentic programs of CAD offering a resolution 3D surprising.

Ease of handle.

The functions of programming and of creation of plans of work of ShopTurn have designed following the principle to happen the before possible of the plane to the piece finished. The software bases in the functions "Look-and-Feel" of ShopMill, the software of handle for milling machines. Thanks to this philosophy and the functions of manufacturing simplifies the work of the technician of mechanised, attaining a greater profitability even with series of a piece.

Milling with ShopTurn.

ShopTurn No only allows to do the classical operations that can do with a motorised tool in a lathe, but besides it allows to program in our lathe even cashiers with islands in the frontal of the piece. This achieves that our machine was much more productive, since operations that had to finish in a fresadora can llevar directly on the lathe, with the big saving that this supposes. All this programmed on some conversational surroundings that does very simple his programming.

The operations that can llevar in a fresadora can now also realise on the lathe thanks to his interpolation between the axis X and the axis C thanks to the ShopTurn. For this also has of the most common cycles of milling for greater ease of handle, like cashiers, vástagos, slots and milling poligonal (to do a hexagon for example). Also it can mill with the tool motorised the surface of the cylinder programming in 2D.

Turning with ShopTurn.

Besides, the functionality of turning is studied cuidar all the details, allowing even the classical operations of desbastado, ranurado, throats, tronzado, threads and review of threads, can program directly the counterpoint, the tray of pieces and the loaders of bars and even a second cabezal, whenever the machine was prepared for this.

The cycle of desbastado is optimised to the maximum, allowing define the piece in the rough to desbastar of 3 different ways, like cylinder, like demasía of outline (for pieces of smelting) or defining we the form of the piece in the rough that we want to desbastar. Of this way save time of mechanised to the not mechanising in empty.

Also in the desbaste can desbastar the piece with a tool whose angle does not allow us realise all the desbaste, and afterwards, with another different tool. The control recognises automatically the residual material that remains without mechanising and finishes it with another tool. This is not exclusive of the cycle of desbastado, but the cycles of ranurado also can detect the residual material to use distinct tools.

Goratu With ShopTurn.

So much the ShopMill like the ManualTurn already are a classical in the models of Goratu, and from does time already offers in his model of bancada bent GST4 the ShopTurn of series. Of this way, Goratu offers with each machine the solution of suitable programming for each need in workshops of mechanised.

The simulation 3D of ShopTurn.

ShopTurn Offers a powerful simulation 3D with possibility to realise a cut to be able to see in 3D the mechanised inner of the piece, as well as rotar the piece 3D in the space with the cut chosen. Besides his representation in screen is own of authentic programs of CAD offering a resolution 3D surprising.

Ease of handle.

The functions of programming and of creation of plans of work of ShopTurn have designed following the principle to happen the before possible of the plane to the piece finished. The software bases in the functions "Look-and-Feel" of ShopMill, the software of handle for milling machines. Thanks to this philosophy and the functions of manufacturing simplifies the work of the technician of mechanised, attaining a greater profitability even with series of a piece.