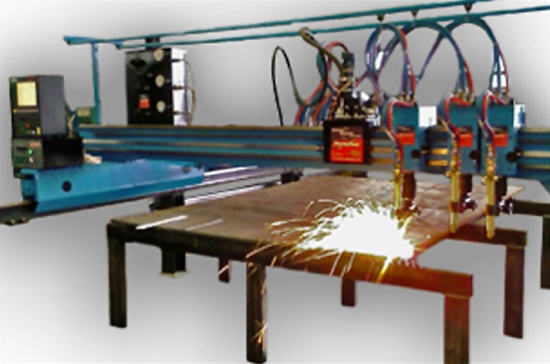

Microstep Spain, S.L. - Oxy-fuel and plasma cutting systems

Microstep N

Machine of oxicorte and of cut by plasma: for the cut of all class of pieces through the control CNC

The basic configuration of the system Portico N composes of:

• A portico of structure very robust guided by both sides on lanes mechanised and accionado by one or both sides (optional) by means of zips and motors cc., being one of them at least floating to compensate the possible errors of parallelism in the longitudinal guides.

• 4 m of lane that provide a longitudinal useful career of 2.000 mm.

• 1 cabezal model P-150, motorised in X and Z and guided on the portico (axis X) by means of zip, threads and metallic strip.

• CNC Edge Especially conceived for machinery of cutting that includes:

• 40 figures parametrizadas

• allows to do Nesting manual

• screen of visualisation

• disquetera 3,5 “ and USB.

• Protection and guided of cables and hoses by chain carries-cables.

• Head office of regulation of automatic gases with regulation systematically electronic from cupboard CNC. And with control of discharge.

Expandable the longitudinal career and the number of cabezales P-150 or S-200 until a total of 4.

The system of cut can be plasma, oxicorte or both systems combined, not having of limitations regarding the last technicians of cutting.

• Control of height capacitivo and lit automatic of the soplete of oxicorte for the cabezal S-200.

• Electronic control of the voltage of reference THC for antorchas of plasma in cabezal S-200.

• Double longitudinal motorisation to reach speeds more elevated in applications with equipment of plasma.

• Connection RS-232 between CNC.

• Software of CAD / CAM: program Post-Processor, conversion of files, manufacturing of attacks and outlines.

The normal speeds of series establish between 0,025 and 6 m/min for simple longitudinal motorisation and between 0.05 and 12 m/min for double longitudinal motorisation (under demand of the customer can be upper).

Technical specifications

Speed máx. pos. Of the cabezal of cutting: 12 m/min

Acceleration of the cabezal of cutting: 1m/s2

mechanical Precision on 1 m: ±0,10 mm

Repetibilidad: ±0,05 mm

hygiene: Mushroom of unemployment of emergency

Motorisation: Motors of C.C. In X, And and Z

Traction: By zips of precision in axles X and And – By husillo in axis Z

Guided: Rails and threads

useful Careers

Axis X: See table

Axis And: Without limit

Axis Z: Cabezal P-150: 150 mm / Cabezal S-200: 200 mm

Protection guided: Scrapers.

Electrical power

Machine: 4 kW.

Plasma: Variable in function of the team

Feeding of the Oxicorte

Oxygen: Pressesure: 6 bar Discharge: 30 m3/h

Propano: Pressesure: 2 bar Discharge: 1,5 kg/h

Feeding Air Compressesed: Dry Air

Discharge dry air: 400 l/min by distributor

Pressesure: 4 to 5 bar

Capacity of load: 150 kg/m2

Colour: RAL 5015.