Spraying Systems Spain, S.L. (Autojet) - Greasing and lubrication equipment

AutoJet

Lubrication of sheet metal: reduce oil consumption up to 90 %

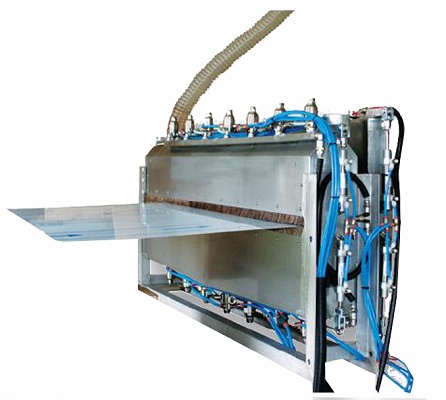

AutoJet lubrication systems enable efficient application of lubricants and corrosion-proof fluid in metal sheets, stamping, wires, tubes and other types of materials in operations of stamping, pressing or deformation.

The accuracy of the Autojet lubrication systems can provide a reduction in the consumption of oil of up to 90% and eliminate the need for further cleaning of parts.

AutoJet L210 lubrication system is suitable for low viscosity lubricants and uses no air nozzles. AutoJet patrol lubrication system is used in processes that require high viscosity oils, up to 600 cSt by spraying with air nozzles. The unique design of the system ensures an environment without pollution and free of oil mist.

Lubricant excessive oil remains inside the Lubricator of sheet metal and is returned to the storage tank. Through valves redirects the lubricant of return to the appropriate tank.

The tanks are not pressurized and can be filled up. The systems have full flow filters to ensure that pollutants do not come to the bombs or nozzles. Switching between different lubricants is easy.