Maconse - Liquid dispensing

Dosing oil and brine: for lines of canned fish, vegetables and olives

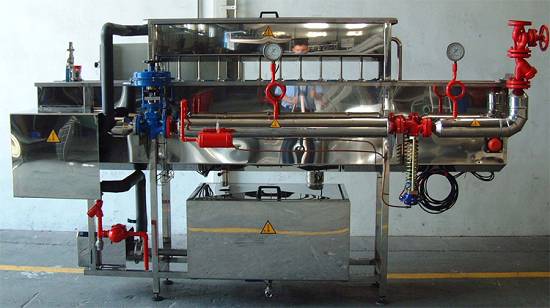

Dosing of liquids; whether Government, oil or brine fluids, the established quantities it dosed for pre-llenar a set minimum amount of liquid prior to definitive filling.

The dosing of liquids, is primarily intended for the food industry, bringing together all the features to apply to containers a very important in the filling phase point, as it is the dosage of liquids for better conservation of the product.

The functioning of this dosing of liquid consists of containers entering the inside of the machine, to use a preset amount of liquid in these containers.

Containers come into the machine in a row and are displaced by its interior thanks to the conveyor that is located inside it. This carrier is in charge of placing the containers under different dosing valves.

Once located the containers under dosing valves, they are filled with the desired fluid fluids shall be deposited in the raft of storage than at the bottom of the machine and using a pump fluid from the raft is sent to a titanium plate heat exchanger, so that the desired temperature is reached, Once the fluid is hot is sent to the top of the machine, where there is a deposit, which spreads the liquid in various metering valves. This deposit in addition to being the intended to spread the liquid over the dosing valves, also consists of an input and output flow constant, so that the liquid will be always recirculating all the circuit flow heating, thus, there is never any variation of temperature.

The dosing of liquids, is primarily intended for the food industry, bringing together all the features to apply to containers a very important in the filling phase point, as it is the dosage of liquids for better conservation of the product.

The functioning of this dosing of liquid consists of containers entering the inside of the machine, to use a preset amount of liquid in these containers.

Containers come into the machine in a row and are displaced by its interior thanks to the conveyor that is located inside it. This carrier is in charge of placing the containers under different dosing valves.

Once located the containers under dosing valves, they are filled with the desired fluid fluids shall be deposited in the raft of storage than at the bottom of the machine and using a pump fluid from the raft is sent to a titanium plate heat exchanger, so that the desired temperature is reached, Once the fluid is hot is sent to the top of the machine, where there is a deposit, which spreads the liquid in various metering valves. This deposit in addition to being the intended to spread the liquid over the dosing valves, also consists of an input and output flow constant, so that the liquid will be always recirculating all the circuit flow heating, thus, there is never any variation of temperature.